Nov . 25, 2024 05:01 Back to list

Essential Measuring Instruments for Precision in Metalworking Tasks

The Essential Measuring Tools in Metalwork

Metalworking is an intricate craft that demands precision and accuracy. Whether one is involved in welding, machining, or fabricating, the success of a project often hinges on the proper use of measuring tools. In this article, we will explore the essential measuring tools utilized in metalwork, highlighting their significance, applications, and how they contribute to achieving high-quality results.

1. Calipers

Calipers are one of the most versatile measuring tools in metalwork. They come in various forms, including vernier, dial, and digital calipers. These tools are designed to measure the dimensions of an object, including internal and external diameters, as well as depth. For instance, a digital caliper provides precise readings with ease, allowing for quick measurements without the need for manual calculations. The accuracy of calipers can significantly reduce errors in cutting or machining processes, making them invaluable for metalworkers.

2. Micrometers

Micrometers are specialized tools designed for measuring small thicknesses or diameters with extreme precision. Typically used for measurements in the thousandths of an inch (or hundredths of a millimeter), micrometers are crucial in applications where tight tolerances are required. Available in various types, such as external, internal, and depth micrometers, these tools help ensure that components fit together correctly and perform as intended. The meticulous nature of metalworking makes micrometers indispensable for high-precision tasks.

Steel rulers are fundamental measuring tools in any workshop. Made from durable materials, they resist bending and damage while providing accurate measurements. Steel tapes, on the other hand, offer flexibility, making them ideal for measuring larger workpieces. Both tools are essential for layout work and initial measurements, allowing metalworkers to mark and cut materials accurately. Their simplicity and reliability make them a staple in every metal shop.

measuring tools in metal work

4. Levels

Levels are crucial for ensuring that workpieces are aligned and properly positioned. A spirit level, for example, helps determine whether a surface is horizontal or vertical. In metal fabrication, maintaining the correct alignment is vital for both aesthetic and functional purposes. Using a level ensures that parts fit together seamlessly, which is especially important in structural applications where integrity is paramount.

5. Angle Finders and Protractors

Angle finders and protractors are essential for measuring and marking angles accurately. In metalwork, many projects require precision cuts and joints at specific angles. Whether it’s for creating a complex metal frame or ensuring that welded joints are aligned correctly, these tools provide the accuracy needed to achieve the desired results. Digital angle finders have also become popular, offering quicker and more precise readings, which can be a huge advantage on the shop floor.

6. Measuring Square

A measuring square, often referred to as a framing square or combination square, is a tool used to check and mark right angles. It allows metalworkers to create accurate layouts and ensure that parts are square to each other during assembly. This tool is particularly useful when cutting and fitting materials, ensuring structural integrity and precision in finished products.

Conclusion

In summary, the right measuring tools are essential for successful metalwork. From calipers and micrometers that provide precise measurements to reliable rulers and squares that assist in layout and alignment, each tool plays a critical role in the fabrication process. By employing these instruments effectively, metalworkers can enhance their craftsmanship, reduce waste, and deliver high-quality results that meet the demands of their projects. As technology advances, the evolution of measuring tools continues, further augmenting the precision and efficiency of metalworking practices. Embracing these essential tools will undoubtedly lead to improved outcomes and greater satisfaction in the artistry of metalwork.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

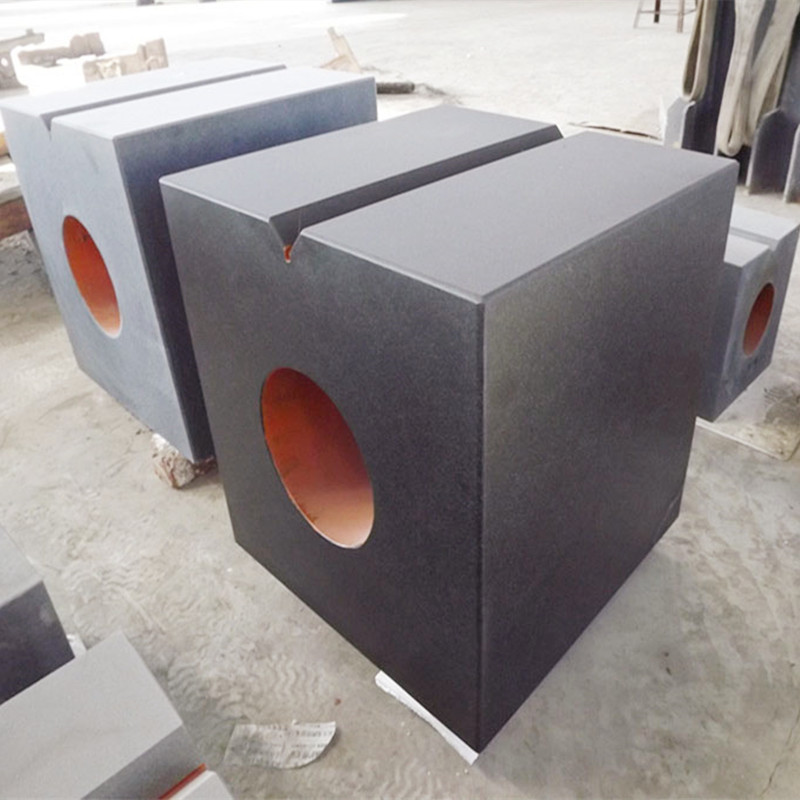

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS