Xan . 14, 2025 13:41 Back to list

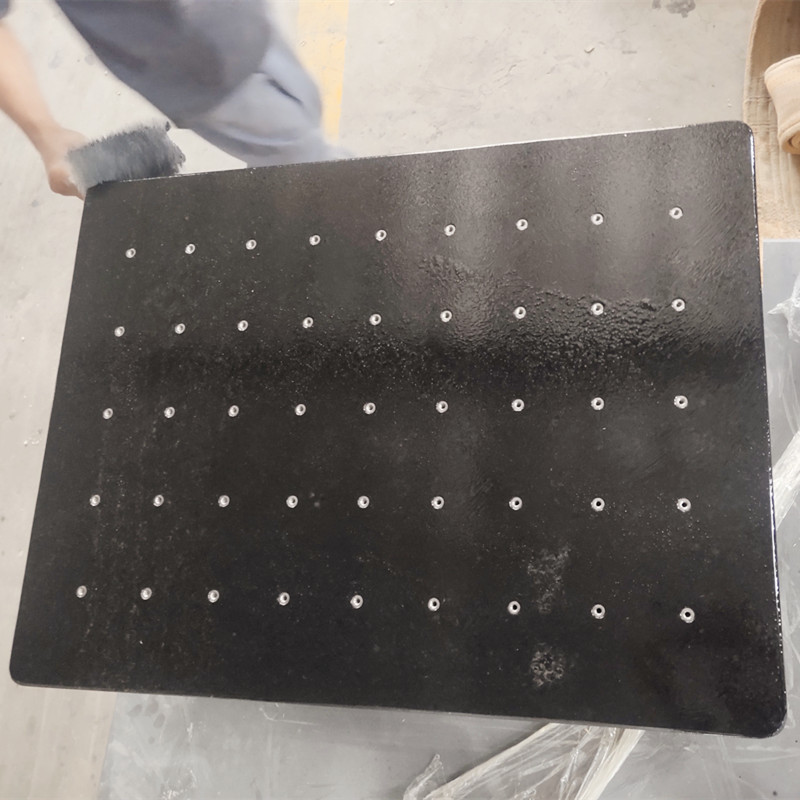

flanged strainer

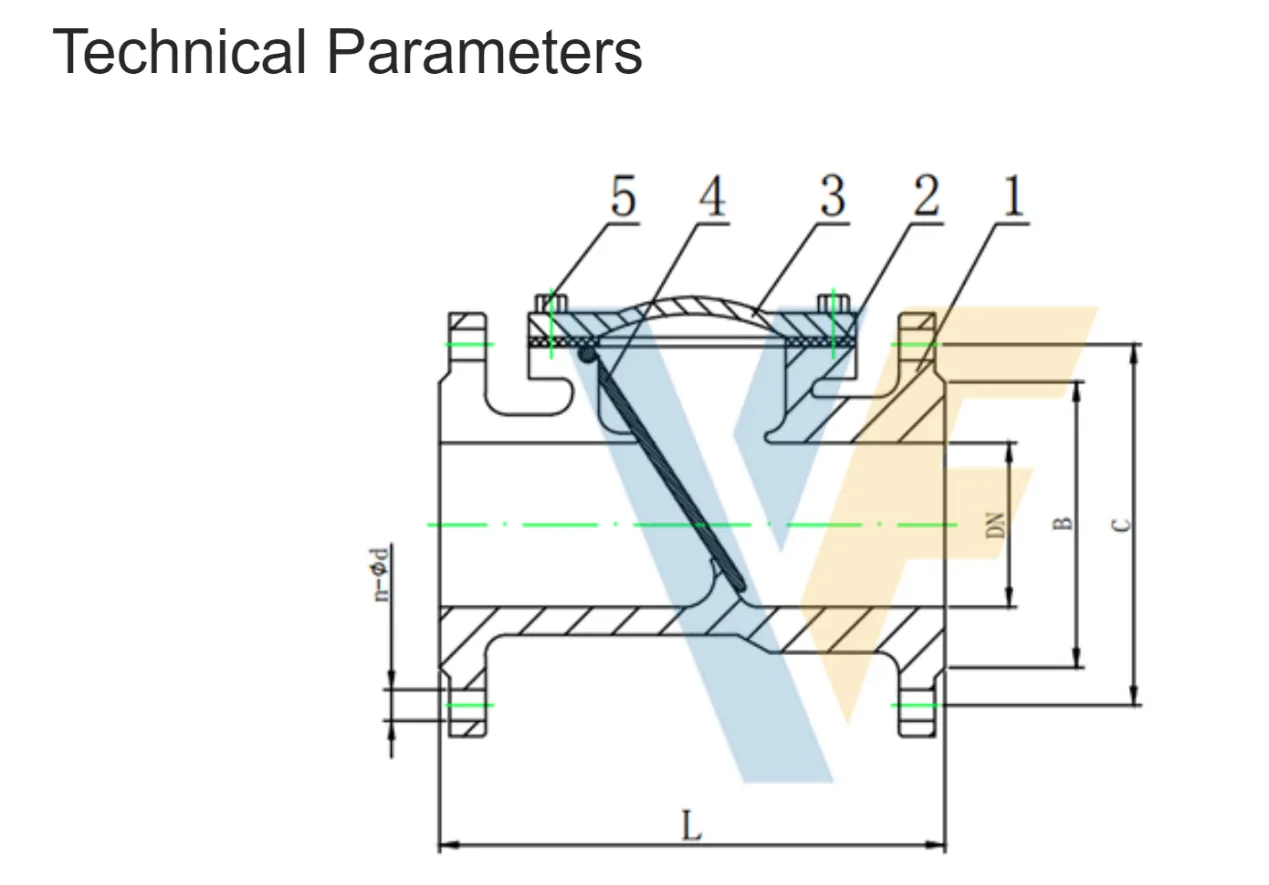

The flanged wye strainer represents a critical component in fluid management systems, offering unique benefits that ensure the longevity and efficiency of various industrial processes. Leveraging years of hands-on experience with diverse mechanical setups, it becomes evident that the flanged wye strainer is not just another industrial tool; it is a cornerstone of fluid control that combines reliability with cutting-edge technology.

Trustworthiness stems from a commitment to delivering consistent and reliable performance under varied working conditions. Engineered with precision, flanged wye strainers are subject to rigorous testing before being integrated into a system. Among these evaluations are hydrostatic testing for pressure resilience and finite element analysis to predict and enhance performance under diverse stress conditions. By surpassing these stringent tests, manufacturers reinforce trust among engineers and procurement specialists, who recognize the enduring value of investing in quality components. From a practical experience standpoint, installing a flanged wye strainer is relatively straightforward, yet it requires attention to manufacturer guidelines to maximize efficiency. Proper installation involves aligning the strainer in the correct flow direction, ensuring flange compatibility, and adequately torquing bolts to prevent leaks. Regular maintenance further boosts reliability, as periodic cleaning and inspection avert potential clogs and maintain system pressure. Incorporating these best practices fosters an environment of preventive care, minimizing unscheduled interruptions and maintaining optimal operational flow. In conclusion, as the backbone of a robust fluid control system, the flanged wye strainer epitomizes the marriage of experience, expertise, authority, and trustworthiness. Its role is multifaceted, delivering exceptional filtration performance, supporting seamless process flow, and protecting valuable downstream components. Anchored by quality manufacturing and stringent compliance with industry standards, the flanged wye strainer emerges as an indispensable asset in any sophisticated fluid management strategy. When chosen and maintained with care, it ensures the promise of operational excellence across a myriad of applications, reaffirming its place as an industry staple.

Trustworthiness stems from a commitment to delivering consistent and reliable performance under varied working conditions. Engineered with precision, flanged wye strainers are subject to rigorous testing before being integrated into a system. Among these evaluations are hydrostatic testing for pressure resilience and finite element analysis to predict and enhance performance under diverse stress conditions. By surpassing these stringent tests, manufacturers reinforce trust among engineers and procurement specialists, who recognize the enduring value of investing in quality components. From a practical experience standpoint, installing a flanged wye strainer is relatively straightforward, yet it requires attention to manufacturer guidelines to maximize efficiency. Proper installation involves aligning the strainer in the correct flow direction, ensuring flange compatibility, and adequately torquing bolts to prevent leaks. Regular maintenance further boosts reliability, as periodic cleaning and inspection avert potential clogs and maintain system pressure. Incorporating these best practices fosters an environment of preventive care, minimizing unscheduled interruptions and maintaining optimal operational flow. In conclusion, as the backbone of a robust fluid control system, the flanged wye strainer epitomizes the marriage of experience, expertise, authority, and trustworthiness. Its role is multifaceted, delivering exceptional filtration performance, supporting seamless process flow, and protecting valuable downstream components. Anchored by quality manufacturing and stringent compliance with industry standards, the flanged wye strainer emerges as an indispensable asset in any sophisticated fluid management strategy. When chosen and maintained with care, it ensures the promise of operational excellence across a myriad of applications, reaffirming its place as an industry staple.

Next:

Latest news

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS