Xan . 31, 2025 05:06 Back to list

Butterfly Valves

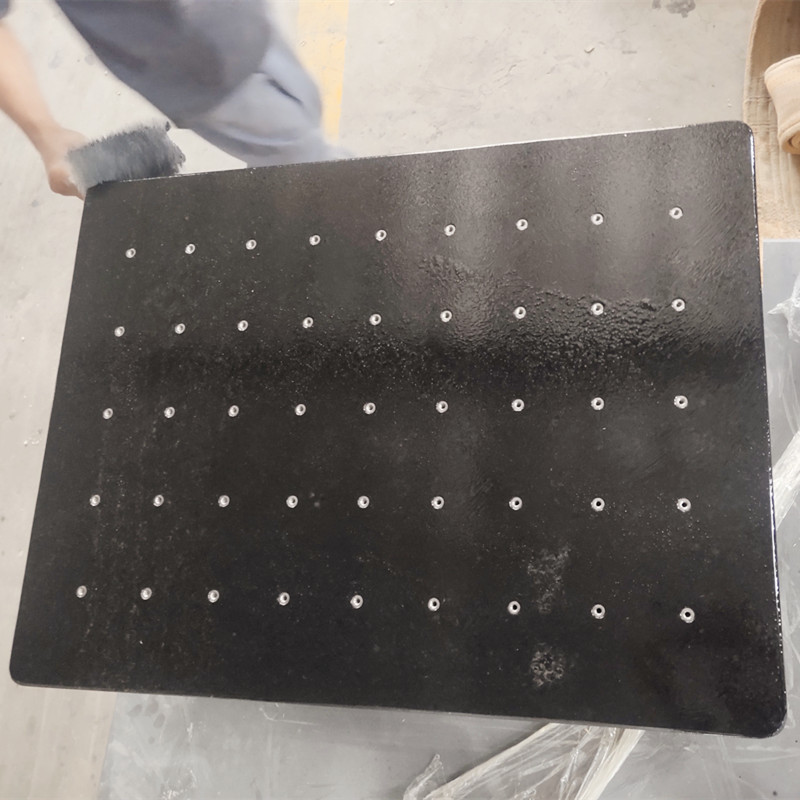

Butterfly valves are pivotal components in industrial applications that require the regulation and isolation of fluid flow. The 300mm butterfly valve holds a special place in sectors demanding precision and efficiency due to its capacity to manage substantial flow rates while remaining compact in design.

The authority of the 300mm butterfly valve in the industry is reinforced by rigorous testing and compliance with international standards such as API, ANSI, and ISO. This compliance ensures that these valves do not just perform optimally but do so consistently under regulated conditions. Moreover, the availability of diverse materials - ranging from cast iron, ductile iron to stainless steels - offers engineers the flexibility to select valves that resist corrosive environments, further boosting confidence in their reliability. Building trustworthiness, especially in critical infrastructure, extends beyond performance. It involves long-term service agreements, responsive customer support, and availability of spare parts. Valves from reputed manufacturers often come with warranties and extensive documentation to support operational parameters, installation guides, and troubleshooting, empowering end-users to maximize valve effectiveness. Investing in a 300mm butterfly valve is not merely a purchasing decision but a strategic partnership with a technology designed to enhance operational efficiencies and safeguard fluid transport systems. When evaluating potential suppliers, consider those who provide comprehensive data, transparent service histories, and customer testimonials that elucidate a balanced equation of performance, durability, and service. In conclusion, the 300mm butterfly valve combines engineering finesse with practical advantages that result in reliable, efficient fluid control. Its proven capacity to deliver under pressure, backed by industry standards, makes it an indispensable asset in achieving seamless operation across a myriad of industrial applications. Whether you are expanding infrastructure or upgrading existing systems, these valves remain a cornerstone of strategic operational planning, ensuring your facilities are equipped to meet current and future demands with confidence.

The authority of the 300mm butterfly valve in the industry is reinforced by rigorous testing and compliance with international standards such as API, ANSI, and ISO. This compliance ensures that these valves do not just perform optimally but do so consistently under regulated conditions. Moreover, the availability of diverse materials - ranging from cast iron, ductile iron to stainless steels - offers engineers the flexibility to select valves that resist corrosive environments, further boosting confidence in their reliability. Building trustworthiness, especially in critical infrastructure, extends beyond performance. It involves long-term service agreements, responsive customer support, and availability of spare parts. Valves from reputed manufacturers often come with warranties and extensive documentation to support operational parameters, installation guides, and troubleshooting, empowering end-users to maximize valve effectiveness. Investing in a 300mm butterfly valve is not merely a purchasing decision but a strategic partnership with a technology designed to enhance operational efficiencies and safeguard fluid transport systems. When evaluating potential suppliers, consider those who provide comprehensive data, transparent service histories, and customer testimonials that elucidate a balanced equation of performance, durability, and service. In conclusion, the 300mm butterfly valve combines engineering finesse with practical advantages that result in reliable, efficient fluid control. Its proven capacity to deliver under pressure, backed by industry standards, makes it an indispensable asset in achieving seamless operation across a myriad of industrial applications. Whether you are expanding infrastructure or upgrading existing systems, these valves remain a cornerstone of strategic operational planning, ensuring your facilities are equipped to meet current and future demands with confidence.

Next:

Latest news

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS