Dùbh . 05, 2024 01:32 Back to list

Explore a Variety of Ring Gauges Available for Purchase Online

The Importance of Ring Gauges in Precision Measurement

In the world of precision engineering and manufacturing, the need for accurate measurement is paramount. Among the tools used for this purpose, ring gauges play a vital role. These cylindrical measuring instruments are essential for ensuring the accuracy of hole diameters in various parts and components across different industries. With advancements in technology and manufacturing methods, there is a growing market for ring gauges, both for sale and for specific applications. This article will delve into the significance of ring gauges, their types, and considerations when purchasing them.

Understanding Ring Gauges

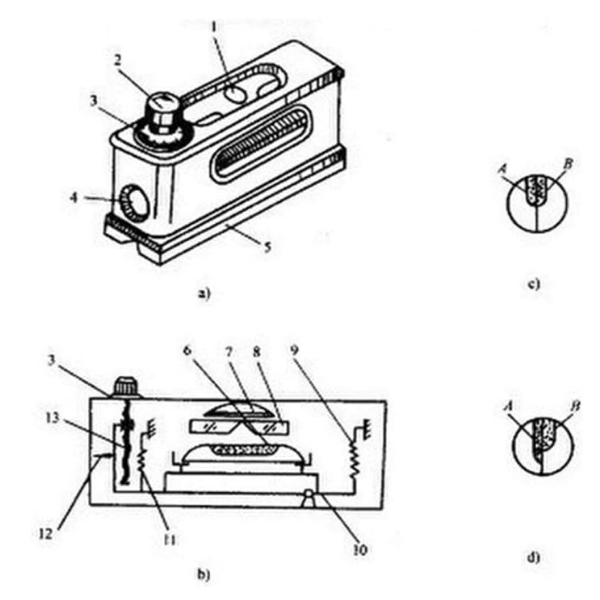

Ring gauges are designed to measure the external diameter of a workpiece, specifically components like shafts, pins, and other cylindrical objects. They are typically made from high-quality steel or other materials resistant to wear and distortion. Two main types of ring gauges are commonly used go gauges and no-go gauges.

1. Go Gauges These are designed to check whether a piece fits correctly within a specified tolerance. If the component passes the go gauge, it indicates that the piece is within acceptable dimensions.

2. No-Go Gauges These assess whether a piece exceeds the upper limit of the tolerance. If the component fits into the no-go gauge, it signifies that the object is out of specification and thus unusable.

These gauges are pivotal in maintaining quality control as they help manufacturers ensure that their products meet stringent dimensional standards.

The Need for Quality

When considering ring gauges for sale, the quality of these measuring tools is of utmost importance. High-quality ring gauges must meet international standards such as ISO and ASME. Purchasing from reputable manufacturers or suppliers guarantees that the gauges have undergone rigorous testing for accuracy and durability. The material used also matters significantly; hardened steel gauges exhibit superior wear resistance, which prolongs their lifespan and retains measurement accuracy over time.

Types of Ring Gauges Available for Sale

Today, the market offers a wide range of ring gauges suited to various applications

- Standard Ring Gauges These are produced according to standard sizes and tolerances.

ring gauges for sale

- Custom Ring Gauges For businesses requiring specific diameters or tolerances, custom gauges are available, providing tailored solutions.

- Measuring Tools with Different Coatings Some ring gauges come with specialized coatings to improve wear resistance or reduce friction, which can enhance measurement accuracy.

- Interchangeable Ring Gauges These allow for flexibility in measurement and are particularly useful in environments where various sizes are frequently needed.

Considerations When Purchasing

When looking for ring gauges for sale, potential buyers should consider several factors

1. Calibration and Certification Ensure the gauges come with calibration certificates, confirming their accuracy. Regular re-calibration is essential for maintaining reliability.

2. Supplier Reputation Purchasing from established suppliers can provide peace of mind regarding the quality of the gauges. Look for companies with a good track record and positive customer feedback.

3. Delivery and Support Consider the supplier's delivery terms and whether they provide post-purchase support. Access to customer service can be crucial for addressing any issues that arise with the gauges.

4. Price vs. Quality While it might be tempting to opt for cheaper gauges, the long-term costs associated with inaccuracies can far exceed the initial savings. Investing in high-quality ring gauges is more economical over time.

Conclusion

Ring gauges are indispensable tools in precision engineering and manufacturing, ensuring that components meet exact specifications and quality standards. With a growing market for these essential measuring tools, it is critical for businesses to understand their importance and wisely consider their options when purchasing. By focusing on quality, supplier reputation, and the specific needs of their applications, manufacturers can enhance their operational efficiency and product reliability. Whether standard or custom, ring gauges play a crucial role in maintaining the integrity of manufacturing processes, making them a worthy investment in any precision-related field.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS