Dec . 26, 2024 00:35 Back to list

vee blocks

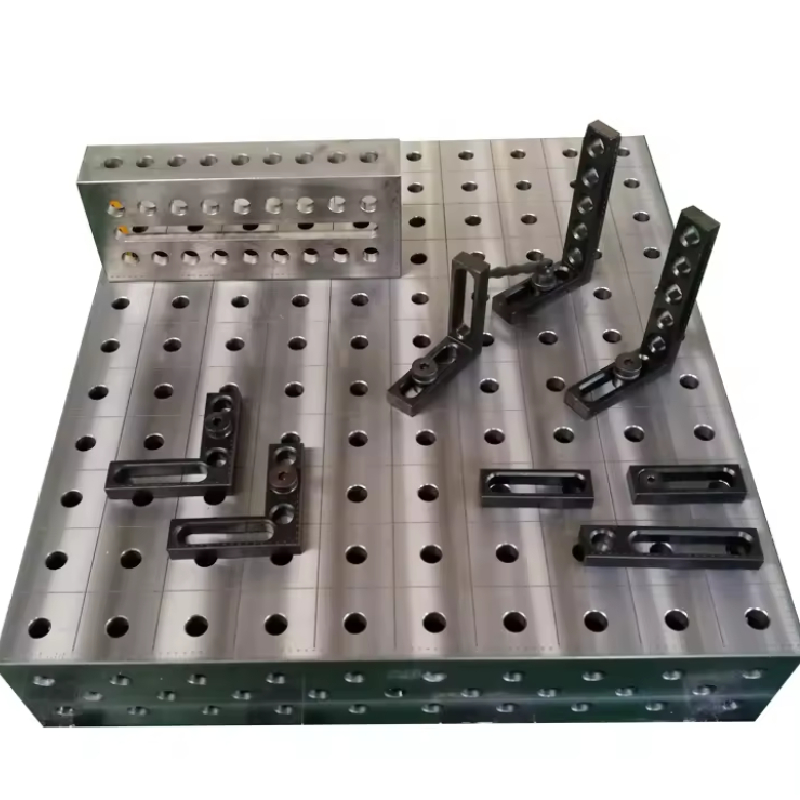

Understanding Vee Blocks Essential Tools in Precision Engineering

In the realm of precision engineering and manufacturing, the importance of accuracy cannot be overstated. Every component that is produced must adhere to strict tolerances to ensure optimal performance, especially in industries such as aerospace, automotive, and machinery. Among the tools that aid engineers and machinists in achieving and verifying such levels of precision are Vee blocks. These fundamental tools play a critical role in the layout and measurement of cylindrical objects, making them indispensable in various machining processes.

What Are Vee Blocks?

Vee blocks are precision tools that typically consist of a block of metal, often made from hardened steel or other durable materials, with one or two accurate V-shaped grooves running along their length. These grooves provide a stable and secure way to hold cylindrical objects, such as rods, pipes, or shafts, in place during machining, inspection, or assembly processes.

The primary function of Vee blocks is to support and stabilize round workpieces, allowing for precise measurements and machining operations. The grooves are designed at specific angles to accommodate various diameters, making Vee blocks versatile for different applications.

Applications of Vee Blocks

Vee blocks have a wide array of applications across different sectors of manufacturing and engineering

1. Machining Setup In the machining process, accurate setups are vital for ensuring that each cut is made according to specifications. Vee blocks provide a solid foundation for cylindrical components, allowing machinists to perform operations like drilling, milling, or grinding with higher accuracy. By securing the workpiece in place, they reduce the risk of movement that could lead to misalignment and subsequent errors.

2. Measurement and Inspection In quality control settings, Vee blocks are paramount in the measurement of cylindrical objects. They are often used in conjunction with micrometers, calipers, or dial indicators. By holding the workpiece securely in the Vee block, inspectors can obtain more accurate readings and ensure that components meet the prescribed specifications.

3. Assembly Work When assembling components that involve rods or shafts, Vee blocks help ensure that everything is aligned and properly fitted. Their stability encourages precision during the assembly process, reducing the likelihood of future mechanical failures.

vee blocks

4. Versatile Applications Beyond cylindrical objects, Vee blocks can also be used creatively in holding various shapes and items. Their design accommodates different workpiece sizes, allowing machinists to adapt and use them for a variety of tasks.

Understanding the Design

The design of Vee blocks adds to their effectiveness. The V-shaped grooves are typically ground to precise angles, ensuring that they can hold cylindrical workpieces firmly and accurately. Some Vee blocks may feature additional elements, such as magnetic bases or accompanying clamps, enhancing their functionality and stability during operation.

Moreover, Vee blocks can be purchased in pairs, allowing for the clamping of a workpiece securely from both sides. This feature is especially useful when working with longer components, ensuring they are immobilized effectively during processing.

Care and Maintenance

While Vee blocks are robust tools, ensuring their long-term accuracy and functionality requires proper care and maintenance. Here are a few best practices

- Cleaning Regularly clean the Vee blocks to avoid the buildup of debris or machining residues that could affect their precision. - Storage Store Vee blocks in a clean, dry environment, preferably in a protective case, to prevent accidental damage or corrosion. - Calibration Periodically check the accuracy of the Vee blocks, especially if they have been subjected to extensive use or heavy loads.

Conclusion

Vee blocks are a vital asset in the precision engineering landscape. Their capacity to securely hold cylindrical components allows for accurate machining, measurement, and assembly, playing a crucial role in the production of high-quality parts. By understanding their applications, design, and maintenance, engineers and machinists can fully leverage the potential of Vee blocks to enhance their workflows and product quality. As technology continues to evolve, the fundamental principles of precision and accuracy embodied by Vee blocks will remain integral to successful manufacturing practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS