Dec . 06, 2024 14:54 Back to list

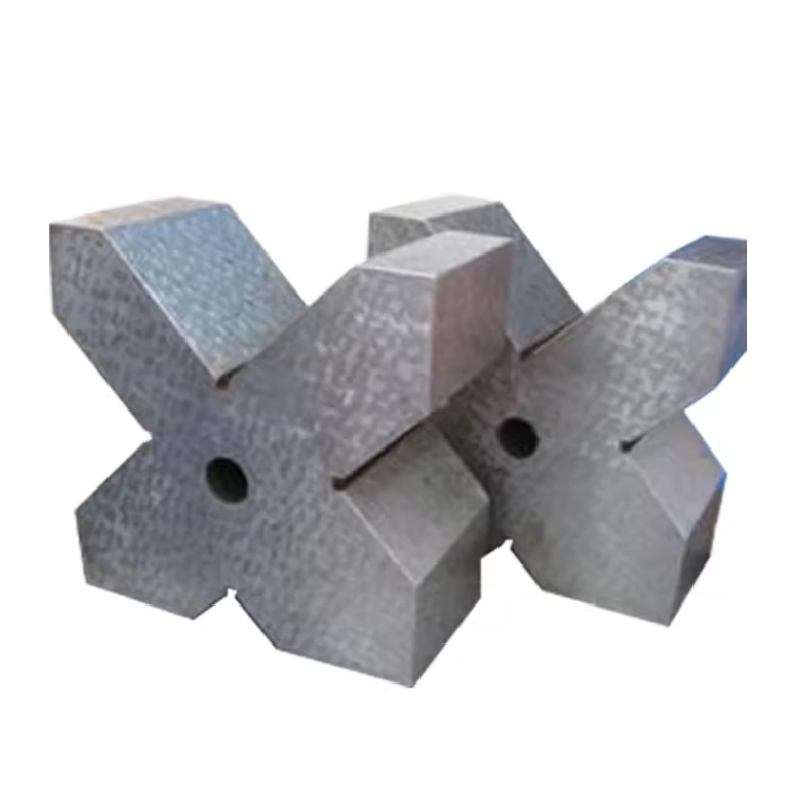

granite inspection block

The Importance of Granite Inspection Blocks in Quality Control

Granite inspection blocks play a critical role in the realm of quality control and precision measurement in various industries, including manufacturing, aerospace, and engineering. These blocks serve as reliable standards against which the dimensional accuracy of components and assemblies can be measured. In an industry that demands high levels of precision, the significance of granite inspection blocks cannot be overstated.

What are Granite Inspection Blocks?

Granite inspection blocks are precision-engineered flat surfaces made from natural granite. Known for their stability and resistance to wear, these blocks provide a consistent and solid reference point for inspection tasks. The material properties of granite—specifically its rigidity, low thermal expansion coefficient, and inherent flatness—make it an ideal medium for these applications. As a result, granite inspection blocks are widely sought after for their durability and accuracy.

Advantages of Using Granite Inspection Blocks

One of the primary advantages of granite inspection blocks is their dimensional stability

. Unlike other materials, granite is less susceptible to changes in temperature and humidity, which can lead to measurement errors. This stability ensures that measurements taken with granite blocks remain accurate, regardless of the environmental conditions, making them particularly useful in precision machining and manufacturing settings.Additionally, granite has excellent wear resistance. This means that frequent usage over time does not significantly alter the surface of the block, maintaining its accuracy for many years. In contrast, softer materials can degrade, leading to incorrect measurements and compromised quality control.

granite inspection block

Another benefit of granite inspection blocks is their ease of maintenance. They can be easily cleaned and leveled, ensuring that they remain in optimal condition for precise measurements. Regular maintenance, such as cleaning with non-abrasive materials, can prolong the life of the inspection block while maintaining its flatness and accuracy.

Applications in Various Industries

Granite inspection blocks are utilized across multiple industries. In manufacturing environments, they are employed to verify the dimensions of machined parts, ensuring that products meet specified tolerances. This is crucial in sectors like aerospace and automotive, where safety and functionality are paramount.

In the field of metrology, granite inspection blocks serve as reference planes for various measurement tools, including calipers, micrometers, and coordinate measuring machines (CMMs). By providing a stable reference, granite blocks help technicians and engineers assess the accuracy of instruments and ensure that they are functioning correctly.

Moreover, granite inspection blocks can be used in conjunction with optical equipment for advanced quality control processes. For instance, they provide a flat surface necessary for laser scanning and other optical measurement techniques, enabling the production of complex components with high precision.

Conclusion

In conclusion, granite inspection blocks are indispensable in ensuring quality and accuracy in various industrial applications. Their unique properties, including dimensional stability, durability, and ease of maintenance, make them the preferred choice for precision measurement tasks. As industries continue to emphasize quality control due to the increasing demands for precision and reliability, granite inspection blocks will remain an essential tool for engineers and technicians alike. Investing in high-quality granite blocks not only enhances measurement accuracy but also contributes to the overall efficiency and output of manufacturing processes. In a world where every detail matters, the role of granite inspection blocks will continue to be pivotal in maintaining the highest standards of quality and precision.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS