Sep . 25, 2024 11:15 Back to list

Role and Function of Control Valves in Hydraulic Systems

The Role of Control Valves in Hydraulic Systems

Control valves are essential components in hydraulic systems, serving a crucial function in the regulation of fluid flow and pressure. These valves are designed to adjust the flow rate, direction, and pressure of hydraulic fluid within a system, allowing for precise control of machinery and processes. Understanding their operation and importance is fundamental for anyone involved in hydraulic engineering or maintenance.

At its core, a control valve functions as a throttle mechanism. By manipulating the size of the passage through which the hydraulic fluid flows, these valves can efficiently regulate the flow rate. When the valve is opened, fluid can flow freely; as it is closed, the flow is restricted, leading to an increase in pressure upstream. This capability is particularly critical in hydraulic systems where precise control is necessary for the safe and efficient operation of machinery, such as cranes, excavators, and industrial presses.

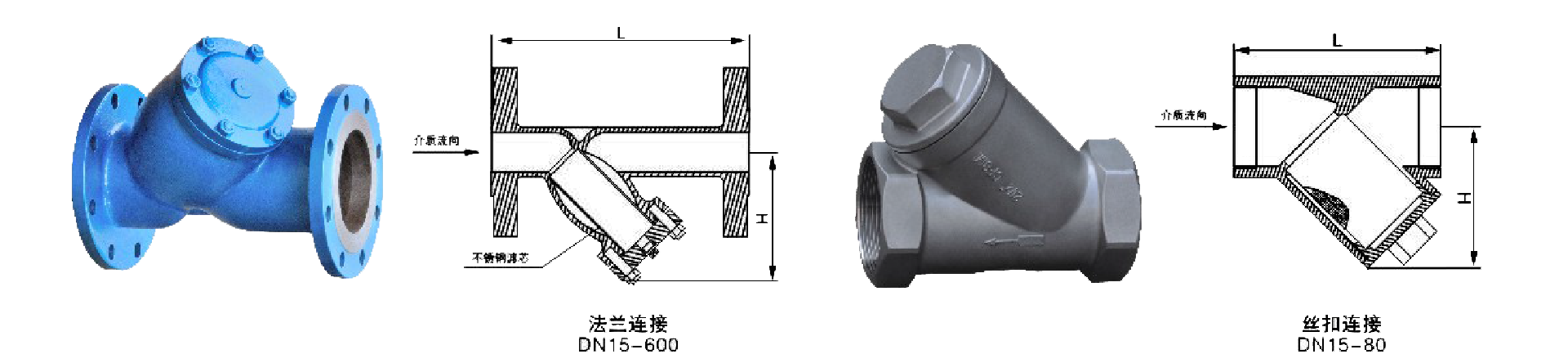

There are various types of control valves used in hydraulic systems, including proportional, servo, and on/off valves. Proportional valves allow for varied control based on the input signal, providing a smooth and responsive adjustment of flow rates. In contrast, servo valves are used for high-performance applications, offering rapid and accurate response times, making them ideal for systems requiring precise positioning and control. On/off valves, while simpler, can serve as effective solutions for systems that do not require fine-tuned flow control.

control valve in hydraulic system

The design and material of control valves are also vital considerations. Constructed from durable materials such as steel, aluminum, or plastic composites, these valves must withstand high pressures and temperatures typically encountered in hydraulic systems. Additionally, the valve's internal components, such as seals and actuators, play a significant role in its performance and longevity.

Regular maintenance and monitoring of control valves are critical to ensuring the reliability and efficiency of hydraulic systems. Leaks, sticking, or wear in components can lead to performance loss and may even result in system failure. Implementing routine inspections and timely replacements can prevent costly downtimes and enhance system safety.

In conclusion, control valves are indispensable in hydraulic systems, providing the necessary functionality to manage fluid flow and pressure effectively. Their various types and crucial roles in different applications underscore their importance in industrial settings. Understanding how these valves operate and maintaining them properly can lead to enhanced productivity, safety, and efficiency in hydraulic machinery, ultimately reflecting their importance in modern engineering and technology.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS