Nov . 22, 2024 17:00 Back to list

working thread plug gage

Understanding Working Thread Plug Gages Importance and Applications

In the world of manufacturing and precision engineering, the need for accuracy cannot be overstated. One of the critical tools that ensure the integrity of threaded components is the working thread plug gage. This specialized tool plays a vital role in maintaining quality control in various industries, particularly in those that require threaded fasteners. In this article, we will delve into the concept of working thread plug gages, their functions, and their applications in various sectors.

What is a Working Thread Plug Gage?

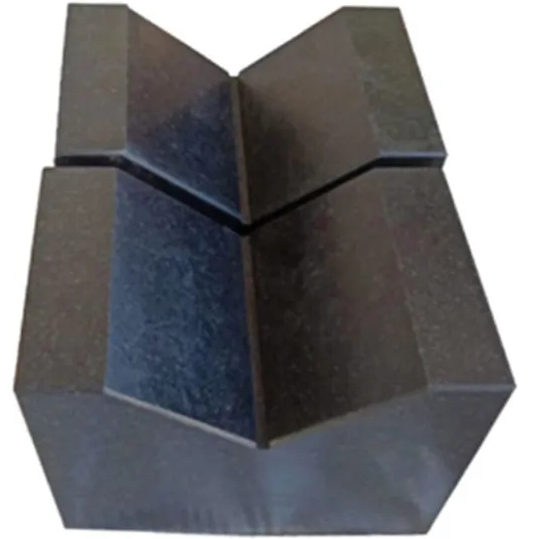

A working thread plug gage, commonly known as a thread plug gage, is a precision tool used to measure the dimensional accuracy of threaded holes. It is designed to fit into a threaded opening and verify that the dimensions conform to specific standards, ensuring that the threads are cut correctly and will mesh properly with mating parts. These gages are typically made from high-strength materials like tool steel and are manufactured with precise tolerances to meet industry specifications.

Types of Thread Gages

There are two primary types of thread gages the Go gage and the No-Go gage.

1. Go Gage This gage is used to check whether the thread dimensions meet the minimum required limits. When the Go gage fits into the threaded hole, it validates that the thread is within acceptable limits and can accept the corresponding screw or bolt.

2. No-Go Gage The No-Go gage verifies the maximum allowable dimensions of the threaded hole. If the No-Go gage fits, it indicates that the thread is oversized and does not meet the required specifications, which could compromise the integrity of the connection.

Importance of Working Thread Plug Gages

working thread plug gage

The primary purpose of a working thread plug gage is to ensure the quality and reliability of threaded components. In many industries, including automotive, aerospace, and manufacturing, the strength and stability of fastened connections are paramount. If a threaded hole does not meet the necessary specifications, it can lead to component failure. Such failures could be catastrophic, especially in applications like aircraft or heavy machinery, where safety is critical.

Using working thread plug gages helps identify defects early in the production process, reducing the likelihood of faulty parts being assembled. This proactive approach to quality control can significantly decrease the costs associated with rework, warranty claims, and product recalls.

Applications in Various Industries

The applications of working thread plug gages are vast and varied. In the automotive industry, they are used to ensure that engine components, chassis parts, and transmission systems meet precise threading specifications. In aerospace, rigorous standards necessitate the use of these gages to guarantee that every bolt, nut, and fastener is of the highest quality.

Manufacturers of machinery and equipment also rely on working thread plug gages to ensure that their products operate safely and effectively. From heavy industrial machines to consumer electronics, the threads on components must be accurate and secure.

Calibration and Maintenance

To maintain the accuracy of working thread plug gages, regular calibration is essential. Calibration ensures that the gages still meet the specified tolerances over time. This can involve comparing the gage measurements with known standards and making adjustments if necessary. Proper storage and handling are also crucial to prevent damage that could affect their precision.

Conclusion

Working thread plug gages are indispensable tools in the realm of precision engineering. Through their application, industries can ensure the reliability, safety, and performance of threaded components. The meticulous nature of threaded connections necessitates the use of specialized gages to uphold quality standards. As industries continue to advance and innovate, the role of working thread plug gages will remain essential in guaranteeing that products are not just functional but also safe and reliable. Investing in high-quality gaging solutions contributes to enhanced production efficiency, reduces the risks of failures, and ultimately leads to greater customer satisfaction.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS