Déc . 06, 2024 10:20 Back to list

Understanding the Functionality and Applications of Steel Check Valves in Fluid Systems

Understanding Steel Check Valves An Essential Component in Fluid Systems

Steel check valves play a critical role in various fluid systems, serving as a safeguard against backflow and ensuring the safe and efficient transport of liquids and gases. These valves operate on a simple yet effective principle, allowing fluid to flow in one direction while preventing reverse flow. This article will explore the functionalities, applications, advantages, and selection criteria of steel check valves.

Functionality of Steel Check Valves

Check valves are automatic devices that open and close in response to fluid flow. In the case of steel check valves, they are typically designed with a hinged or spring-loaded disc that opens when upstream pressure exceeds the force of gravity and the spring. When the flow decreases or reverses, the disc closes under the influence of gravity or the spring tension, thereby stopping backflow. This functionality is crucial in maintaining system integrity and protecting equipment from potential damage caused by backpressure.

Applications of Steel Check Valves

Steel check valves are widely used in various industries due to their robust construction and reliability. Common applications include

1. Water and Wastewater Treatment In municipal water systems, steel check valves prevent backflow, protecting water sources and ensuring the consistent delivery of clean water.

2. Oil and Gas In petroleum applications, these valves are essential in pipelines and refineries, safeguarding against leaks and ensuring the smooth transport of hydrocarbons.

3. Power Generation Check valves in power plants help manage the flow of steam and water, essential for maintaining operational efficiency and protecting critical infrastructure.

4. HVAC Systems Steel check valves are used in heating, ventilation, and air conditioning systems to control the flow of fluids and maintain system pressure.

5. Industrial Processes They are integral in various manufacturing processes, where fluid control is essential for operational efficiency and safety.

Advantages of Steel Check Valves

1. Durability Made from high-grade steel, these valves are designed to withstand harsh conditions, including high temperatures and pressures, making them suitable for a wide range of applications.

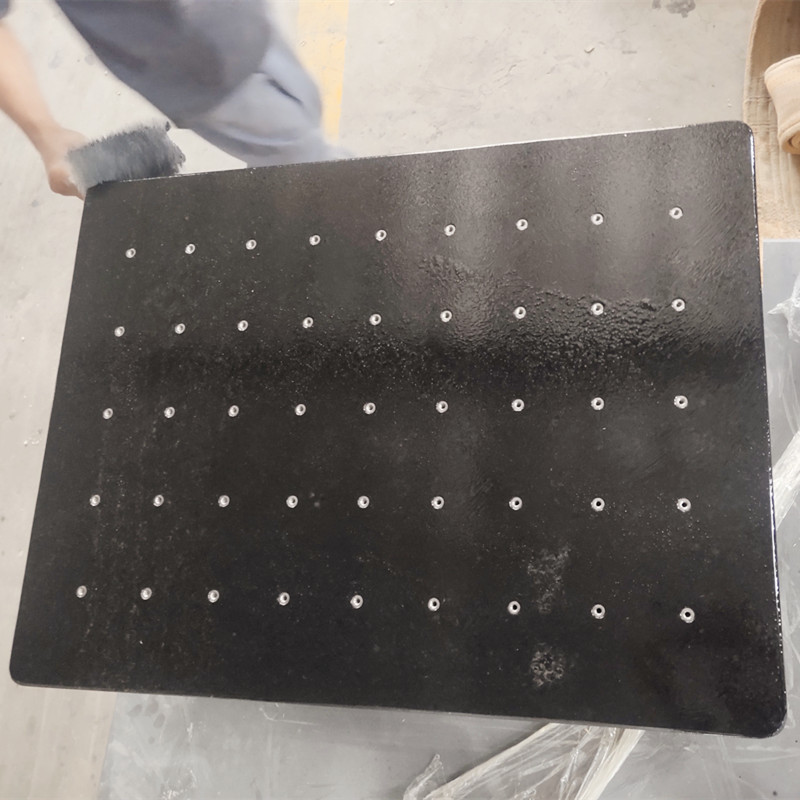

steel check valve

2. Corrosion Resistance Many steel check valves are treated or coated to resist corrosion, ensuring longevity even in aggressive environments.

3. Low Maintenance With fewer moving parts compared to other valve types, steel check valves require minimal maintenance, leading to lower operational costs.

4. Efficient Operation Their design allows for quick response to flow changes, ensuring optimal performance without manual intervention.

Selecting the Right Steel Check Valve

When choosing a steel check valve, several factors should be considered

1. Flow Characteristics Understand the flow rate and pressure requirements of your system to select an appropriately sized valve.

2. Type of Fluid Different fluids (e.g., high-temperature steam, corrosive chemicals) may require specific materials or designs.

3. Installation Environment Consider environmental factors, such as temperature and pressure conditions, which can affect valve selection.

4. Standards and Regulations Ensure the selected valve complies with industry standards and regulations, which may vary by region and application.

5. Maintenance Requirements Evaluate how often maintenance will be needed and the ease of accessing the valve for repairs.

Conclusion

Steel check valves are essential components in many fluid systems, providing reliability and safety. Their durable construction and efficient operation make them a preferred choice across various industries. By understanding their functionality, applications, advantages, and selection criteria, engineers and operators can ensure the optimal performance of fluid systems while protecting their investments in infrastructure and equipment.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS