نوامبر . 19, 2024 14:40 Back to list

Understanding and Using Standard Bore Gauges for Precision Measurements

Understanding Standard Bore Gages A Comprehensive Overview

In the realm of precision measurement, standard bore gages play a crucial role in ensuring the accuracy and quality of cylindrical parts and components. These specialized tools are essential for industries that require meticulous tolerances and consistent performance, including manufacturing, automotive, aerospace, and heavy machinery sectors. This article explores what standard bore gages are, how they function, their applications, and their significance in industrial settings.

What is a Standard Bore Gage?

A standard bore gage is a measuring instrument specifically designed to assess the internal dimensions of cylindrical holes or bores. It is used to determine various parameters, such as diameter, roundness, and finish, ensuring that the internal dimensions of a component meet the required specifications. Standard bore gages can range from simple, mechanical versions to sophisticated electronic models that provide advanced data analysis and reporting capabilities.

How Do Bore Gages Work?

The basic operation of a standard bore gage involves inserting the gage into the bore to measure its diameter. The gage typically consists of a measuring head and a pair of contact points, which expand or contract to fit the internal dimension of the bore. The measured diameter is read on a scale or a digital display, depending on the design of the gage.

There are several types of bore gages, including

1. Mechanical Bore Gages These use mechanical components like springs and levers to perform measurements. Operators read the measurement directly off a dial or scale. Although often less expensive, mechanical gages can be prone to user error and require careful handling.

2. Electronic Bore Gages More advanced than their mechanical counterparts, electronic gages incorporate digital displays and sensors to provide precise measurements. They often feature data output options for easy integration with manufacturing software, enabling real-time quality control and monitoring.

3. Dial Indicator Bore Gages Utilizing a dial indicator to measure deviations from a reference point, these gages provide accuracy and a rapid assessment of hole roundness and straightness.

Applications of Standard Bore Gages

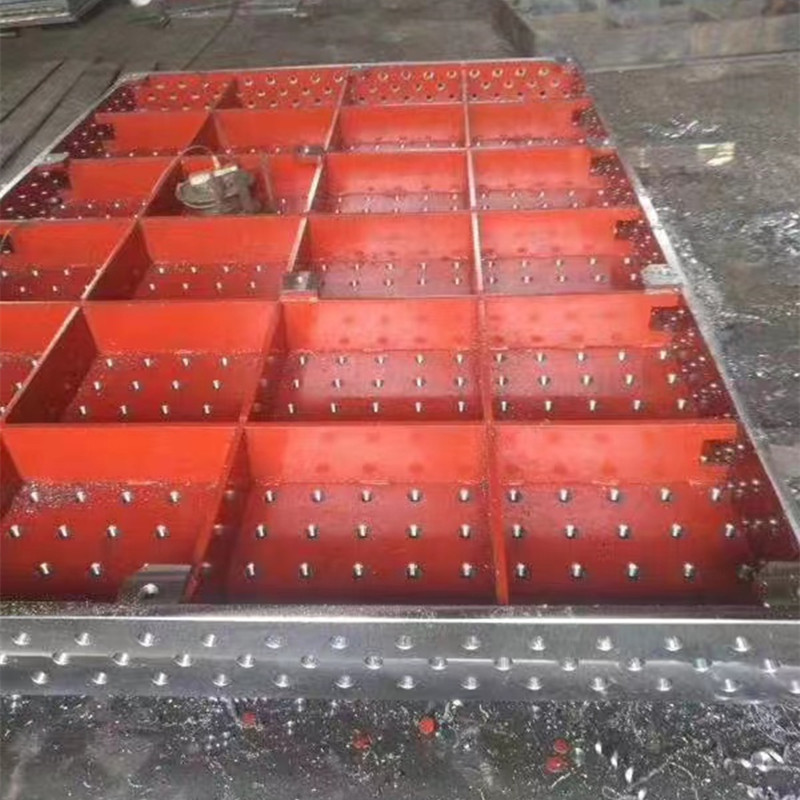

standard bore gage

Standard bore gages are utilized across various industries for diverse functions, including

- Quality Control Ensuring that machined components meet specified tolerances is paramount for maintaining product integrity. Bore gages are instrumental in quality assurance processes, helping to identify deviations before parts go into production or assembly.

- Manufacturing Automated and manual manufacturing processes often rely on bore gages to verify that components fit together as designed. This measurement is vital for assembly lines, where even the slightest variation can affect performance or lead to equipment failure.

- Maintenance and Repair In maintenance operations, standard bore gages help technicians assess the wear of components over time. For instance, in automotive or aerospace applications, understanding bore wear is crucial for maintaining engine performance and safety.

Importance of Using Standard Bore Gages

Utilizing standard bore gages ensures precision in manufacturing processes, reducing costs associated with rework and scrap. By accurately measuring bore dimensions, manufacturers can enhance product quality, leading to improved customer satisfaction and market competitiveness.

In addition, standardizing measurement practices through the use of bore gages helps maintain consistency across production lines. This consistency is essential, especially in industries where safety and regulatory compliance must be adhered to.

Moreover, the evolution of technology has enhanced the capabilities of bore gages. With features such as data logging, automated measurements, and ease of integration into digital workflows, modern bore gages provide manufacturers with powerful tools to meet the challenges of contemporary production environments.

Conclusion

Standard bore gages are indispensable tools in the world of precision measurement, providing a means to measure and ensure the internal dimensions of cylindrical components. From quality control in manufacturing to maintenance assessments, these tools play a significant role in maintaining the accuracy and reliability of products across various industries. With advancements in technology, the capabilities of bore gages continue to expand, making them even more valuable in today's highly competitive market. As industries seek to improve efficiency and reduce costs, the adoption of standard bore gages will undoubtedly play a pivotal role in achieving these goals.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS