ژوئن . 20, 2025 09:19 بازگشت به لیست

Control Valve Selection Criteria for Water Treatment Plants

Selecting the right control valves for water treatment plants is critical to ensuring efficient operation, longevity, and compliance with industry standards. Control valves regulate flow, pressure, and direction of water within treatment processes, directly impacting system performance. This article outlines the essential criteria for selecting control valves, focusing on control valve sizing, control valve sizing standard, control valve types, and applications for control valve 1 2 inch. By understanding these factors, engineers and plant operators can make informed decisions that align with operational demands and regulatory requirements.

Understanding Control Valve Sizing for Optimal Performance

Control valve sizing is the foundation of effective valve selection. An improperly sized valve can lead to inefficiencies, such as excessive pressure drops, cavitation, or inadequate flow control. For water treatment plants, accurate sizing ensures the valve operates within its optimal range, minimizing wear and energy consumption.

Key factors influencing control valve sizing include:

- Flow Rate: The maximum and minimum flow rates determine the valve’s capacity. Oversized valves may fail to modulate precisely, while undersized valves restrict flow.

- Pressure Drop: The difference between upstream and downstream pressure affects valve selection. High-pressure drops require robust materials and designs to prevent erosion.

- Fluid Properties: Water temperature, viscosity, and potential contaminants influence material compatibility and sealing mechanisms.

- Valve Characteristics: Linear, equal percentage, or quick-opening flow traits must align with process requirements.

Using industry-standard software or formulas, engineers calculate the valve’s flow coefficient (Cv) to match system parameters. This ensures the control valve operates efficiently across its entire range.

Adhering to Control Valve Sizing Standards in Water Treatment

Compliance with control valve sizing standards guarantees reliability, safety, and interoperability. Standards such as ISO 5208, ANSI/ISA-75.01.01, and AWWA specifications provide guidelines for design, testing, and installation.

Key aspects of control valve sizing standards include:

- Leakage Classifications: Standards define acceptable leakage rates (e.g., Class IV or VI) based on application criticality.

- Pressure-Temperature Ratings: Valves must withstand system pressures and temperatures without deformation.

- Material Specifications: Standards mandate corrosion-resistant materials like stainless steel or PVC for water treatment environments.

- Testing Protocols: Hydrostatic, pneumatic, and endurance tests validate performance under simulated operating conditions.

Adhering to these standards ensures that control valves meet regulatory requirements and perform reliably in demanding water treatment applications.

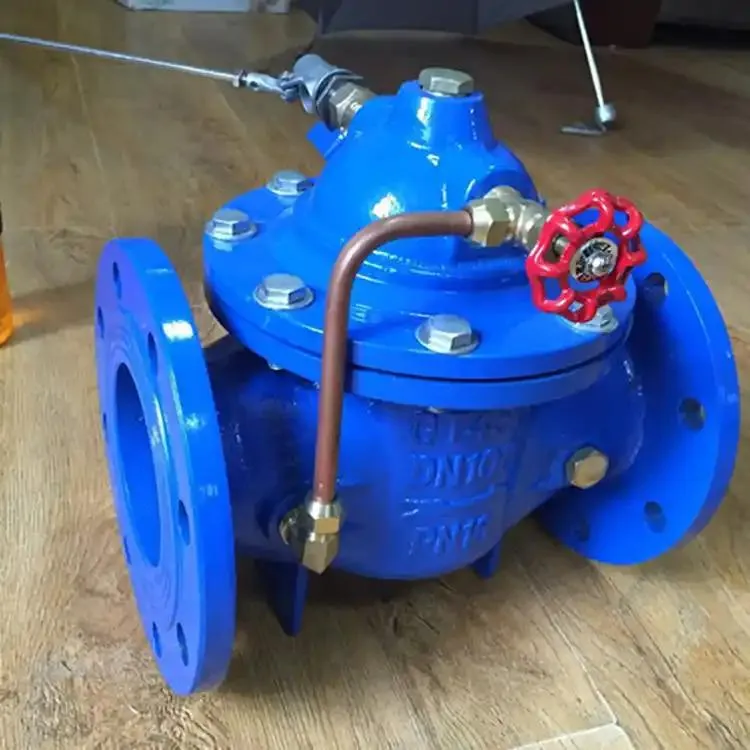

Types of Control Valves for Water Treatment Systems

Selecting the right control valve type depends on the specific application within the water treatment process. Common types include:

- Globe Valves: Ideal for precise flow control, these valves feature a linear motion stem and plug design.

- Butterfly Valves: Compact and cost-effective, they suit large-diameter pipelines with moderate pressure drops.

- Ball Valves: Known for quick shut-off, they are used in applications requiring minimal leakage.

- Diaphragm Valves: Resistant to corrosive fluids, these valves excel in chemical dosing systems.

For smaller pipelines, the control valve 1 2 inch offers a balance between flow capacity and space efficiency. These valves are commonly used in dosing systems, sampling lines, or auxiliary processes where precise control is paramount.

Applications and Benefits of Control Valve 1 2 Inch in Water Treatment

The control valve 1 2 inch is a versatile component in water treatment plants, particularly in auxiliary systems requiring precise flow regulation.

Key applications include:

- Chemical Injection: Accurate dosing of coagulants or disinfectants.

- Sampling Systems: Controlled extraction of water samples for quality testing.

- Pressure Relief: Managing pressure in secondary pipelines to protect sensitive equipment.

Benefits of the control valve 1 2 inch:

- Compact Design: Fits into tight spaces without compromising performance.

- Precision Control: Ensures accurate modulation for low-flow applications.

- Durability: Constructed from materials like brass or stainless steel for long-term reliability.

FAQs About Control Valves in Water Treatment

What factors are critical for proper control valve sizing?

Proper control valve sizing depends on flow rate, pressure drop, fluid properties, and valve characteristics. Accurate Cv calculations ensure optimal performance.

Which control valve sizing standards apply to water treatment plants?

Common control valve sizing standards include ISO 5208 for leakage testing and ANSI/ISA-75.01.01 for flow capacity calculations.

How does a control valve 1 2 inch differ from larger valves?

A control valve 1 2 inch is designed for low-flow applications, offering precision in compact systems like chemical dosing or sampling.

What materials are recommended for control valves in corrosive environments?

Stainless steel, PVC, or lined materials are recommended for control valves exposed to corrosive chemicals or saline water.

Can a control valve be retrofitted into an existing system?

Yes, provided the control valve matches the pipeline’s size, pressure rating, and material specifications.

Selecting the right control valve for water treatment plants requires a thorough understanding of control valve sizing, adherence to control valve sizing standards, and knowledge of valve types like the control valve 1 2 inch. By prioritizing these criteria, plants can enhance operational efficiency, reduce maintenance costs, and ensure compliance with industry regulations. Whether for large-scale flow management or precision dosing, the correct valve choice is pivotal to the success of water treatment processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlاخبارAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseاخبارAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsاخبارAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesاخبارAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingاخبارAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlاخبارAug.05,2025

محصولات مرتبط