Urr . 18, 2024 18:01 Back to list

Understanding the Functionality and Applications of Thread Snap Gages in Measurement

Understanding Thread Snap Gages A Comprehensive Overview

Thread snap gages are precision tools used primarily in the manufacturing and inspection of threaded components. Their primary function is to measure the pitch diameter and ensure the conformity of threaded parts to specific standards. This article delves into the various aspects of thread snap gages, including their design, applications, benefits, and the essential role they play in quality assurance within various industries.

Design and Functionality

Thread snap gages are typically made from high-quality materials that resist wear and corrosion, ensuring longevity and accuracy. The design consists of a body that houses a set of measuring jaws. These jaws are engineered to engage with the thread profile of a screw, bolt, or any other threaded item. The snap gage operates on the principle of taking direct snap measurements; the operator will insert the gage onto the threaded part and then close the jaws to obtain a measurement. This simplicity of operation allows for quick assessments without requiring extensive training.

When selecting a thread snap gage, it's crucial to consider the specific thread standard—such as Unified National Thread (UN), Metric Thread (M), or British Standard Whitworth (BSW)—since gages are often designed for particular thread types. Additionally, thread snap gages can vary in terms of size, with options available for both small and large applications, enabling versatility in use.

Applications

Thread snap gages find applications across multiple sectors, including automotive, aerospace, machinery, and construction. In the automotive industry, for instance, ensuring that bolts and screws meet precise specifications is critical for vehicle safety and performance. Similarly, in aerospace, thread integrity can mean the difference between success and failure in critical applications. Hence, using thread snap gages helps mitigate the risk associated with using subpar threaded components.

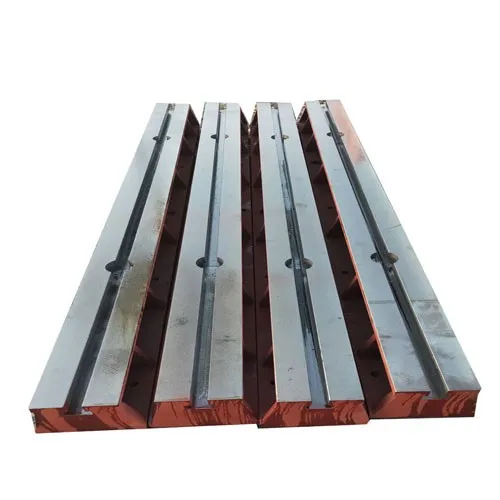

thread snap gage

Aside from physical measurement, thread snap gages can also assist in the production process by providing immediate feedback on the quality of threaded parts. By integrating these tools into manufacturing lines, companies can ensure that any deviations from specifications are identified promptly, reducing waste and enhancing overall productivity.

Benefits of Thread Snap Gages

The benefits of utilizing thread snap gages are numerous. First and foremost, they provide high accuracy and reliability in measurements, crucial for maintaining quality control. Unlike calipers or other general measuring tools, thread snap gages are specifically designed to fit the intricacies of threaded profiles, resulting in more precise outcomes.

Moreover, they contribute to efficiency in manufacturing processes. By facilitating quick checks during production, companies can streamline their operations and avoid costly delays caused by rework or defective products. The simplicity of their design means that workers can quickly learn to use these gages, reducing the time needed for training and operational delays.

Additionally, the use of thread snap gages can enhance compliance with industry standards. Most industries have strict regulations regarding product quality and performance. By employing thread snap gages to ensure conformity, manufacturers can provide assurance to their clients and stakeholders that their products meet or exceed required specifications.

Conclusion

In conclusion, thread snap gages are indispensable tools in the world of threaded component manufacturing and inspection. Their ability to provide accurate and efficient measurements allows companies to uphold high standards of quality control, ensuring the reliability and safety of their products. As industries continue to advance and innovate, the role of thread snap gages will remain significant, driving improvements in manufacturing processes and product integrity. Understanding and utilizing these tools effectively is essential for any organization aiming to succeed in a competitive market.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS