sept. . 25, 2024 15:49 Back to list

bore gauge 0001

Understanding the Bore Gauge A Comprehensive Overview

In the world of precision engineering and manufacturing, accurate measurement plays an integral role in ensuring the quality and reliability of components. One of the key tools used for this purpose is the bore gauge. This specialized instrument is designed to measure the internal diameters of cylindrical objects, providing crucial data to engineers, machinists, and quality control professionals. This article delves into the significance of bore gauges, specifically focusing on the model often referred to as bore gauge 0001, and explores its features, applications, and benefits.

What is a Bore Gauge?

A bore gauge is a measuring device used to determine the internal diameter of a hole, shaft, or any cylindrical feature. Unlike general measuring tools such as calipers, bore gauges are designed to provide a higher degree of accuracy and precision, making them essential in fields like automotive manufacturing, aviation, and machining. The bore gauge typically consists of a handle, measuring probes, and a dial or digital display that shows the measurement.

The Bore Gauge 0001

The bore gauge model 0001 is particularly noteworthy due to its precision and user-friendly design. It is typically calibrated to measure dimensions with an accuracy of up to 0.001 inches, hence the name 0001. This level of precision allows for fine adjustments and assessments, making it a favorite among professionals who require meticulous precision in their work.

One of the defining features of the bore gauge 0001 is its ability to provide measurements in both imperial and metric units, making it versatile for use in different regions and industries

. The construction usually includes hardened steel tips for durability, and often features a spring-loaded mechanism that allows for easy insertion and removal from bore holes while maintaining consistent probe force.Applications of Bore Gauges

The bore gauge 0001 finds applications in various industries, primarily those that require stringent tolerance levels. Some notable applications include

1. Automotive Industry In the automotive sector, bore gauges are employed to measure cylinder bores in engines, ensuring that they meet specific tolerances for effective performance and longevity.

2. Aerospace Given the critical safety requirements of components in aerospace, bore gauges are indispensable for measuring and verifying the integrity of parts like fuselage frames and engine housings.

bore gauge 0001

3. Machine Shops Machinists frequently use bore gauges during the setup and inspection of machined parts. Ensuring that internal diameters are within specified limits is paramount in producing high-quality components.

4. Quality Control In any industry that manufactures precision parts, bore gauges are vital in quality control processes. They help in identifying defects and deviations from specifications, allowing for corrective actions to be taken promptly.

Benefits of Using Bore Gauges

The use of a bore gauge, especially the bore gauge 0001, offers several advantages

1. High Precision The primary benefit is the level of precision it provides. With a resolution of 0.001 inches, users can achieve highly accurate measurements that are essential in fields where tolerances are tight.

2. Ease of Use Most bore gauges, including the 0001 model, are designed for ease of use. They usually come with clear graduated scales and straightforward operational mechanisms, making them accessible even for those with minimal experience.

3. Durability Bore gauges are often constructed from high-quality materials, ensuring they withstand the rigors of daily use in industrial environments.

4. Versatility With options to measure different sizes and units, bore gauges can be adapted for a wide range of applications and industries.

Conclusion

In conclusion, the bore gauge, particularly the bore gauge 0001, is an essential tool for anyone involved in precision measurement. Its high accuracy, user-friendly design, and versatility make it invaluable in industries that demand rigorous quality control and adherence to specifications. As technology progresses and industries continue to evolve, the role of precision instruments like bore gauges will remain critical in maintaining the standards of quality and reliability that define successful manufacturing practices. Whether in automotive, aerospace, or general machining, the bore gauge is a testament to the importance of precision in the modern manufacturing landscape.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

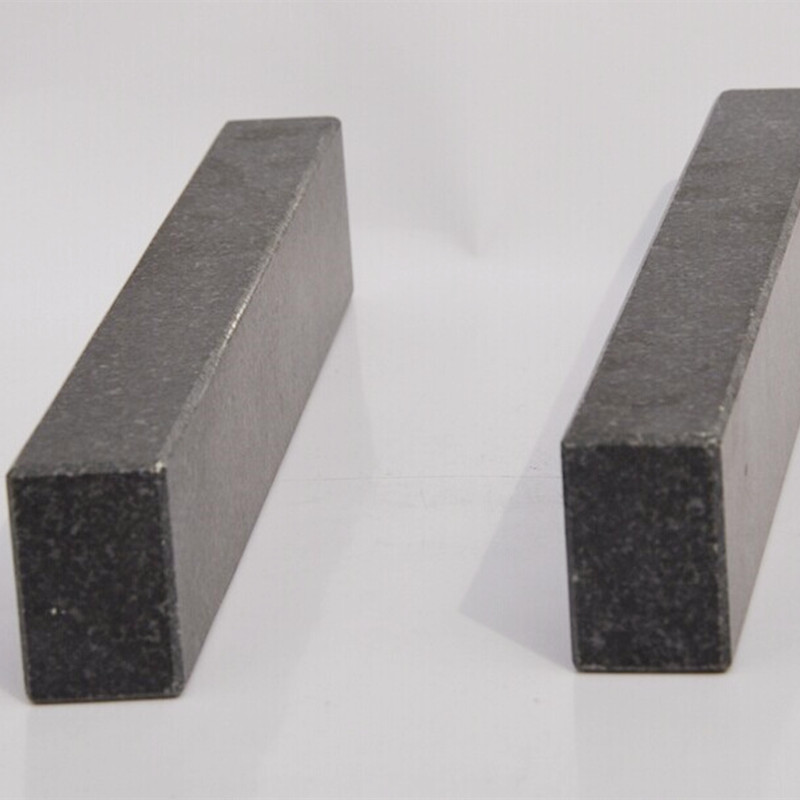

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS