Paralela Reganto

Priskribo de la produkto

Magnezia aluminio-regantoj estas plejparte dividitaj en du tipojn laŭ malsamaj industrioj: regantoj de peza industrio kaj regantoj de malpeza industrio. Pezindustriaj regantoj estas plejparte faritaj el gisfero kaj gisŝtalaj materialoj, dum malpezindustriaj regantoj estas plejparte faritaj el materialoj kiel ekzemple magnezia aluminio, alojŝtalo, kaj rustorezista ŝtalo. La specifa formo kaj modelo de la magnezia aluminio-regulo povas esti desegnitaj laŭ realaj bezonoj.

Magneziaj aluminio-regpunktoj:

- 1.Apliko de magnezia aluminio-regulo: instalado, ebenigo, bontenado kaj mezurado de teksaĵa maŝinaro.

- 2.Magnezia aluminio-regulo estas malpeza: 3-metro-longa regulo pezas nur 9kg.

- 3.Magnezia aluminio-regulo estas oportuna por uzi: 6-metra reganto permesas al laboristoj facile moviĝi kaj mezuri.

- 4.Magnezio-aluminiaj regantoj ne facile misformiĝas: la fleksa punkto de ĝeneralaj ŝtalaj materialoj estas 30kg/mm2, kaj tiu de ĝeneralaj feraj partoj estas 38kg/mm2. La fleksa punkto de ĉi tiu materialo atingas 110kg/mm2, kaj ĝia fleksebla rezistindekso multe superas aliajn materialojn.

- 5.Magnezio-aluminiaj regantoj estas facile stokeblaj: ili povas esti penditaj aŭ metitaj plataj, kaj ilia rekteco kaj paraleleco ne estos tuŝitaj de longdaŭra plata lokigo.

- 6.Magnezio-aluminiaj regantoj ne facile rustiĝas: ne apliku oleon dum uzo, ne uzu dum longa tempo, milde apliku maldikan tavolon de ĝenerala industria oleo dum konservado.

Devenloko: Hebejo, Ĉinio

Garantio: 1 jaro

Agordita subteno: OEM, ODM, OBM

Marka Nomo: Storan

Modelnumero: 3002

Materialo: Aluminia Magnezia Alojo

Precizeco: personecigita

Operacia Reĝimo: personecigita

Item Pezo: personecigita

Kapacito: personecigita

Materialo: Materialo Aluminia Magnezia Alojo

Specifo: vidu kunan formularon aŭ agordu

Fizika rendimento: 47 kg/mm

Etendebleco: 17%

Rendigpunkto: 110 kg/mm2

Working temperature:(20±5)℃

Precizeca grado: 1-3

Pakado: lamenligna skatolo

Plumbotempo

|

Kvanto (pecoj) |

1 - 1200 |

> 1200 |

|

Antaŭtempa tempo (tagoj) |

30 |

Intertraktenda |

Magnesium Aluminum Parallel Ruler: 110kg/mm² Yield Strength for Anti-Deformation

In industrial alignment and precision measurement, the risk of ruler deformation under load can compromise accuracy—until now. Storaen’s magnesium aluminum parallel ruler combines a robust 110kg/mm² yield strength with lightweight design, delivering unmatched anti-deformation performance for applications where dimensional stability is non-negotiable. Here’s how our engineering transforms parallel ruler use in challenging environments:

1. The Science of 110kg/mm² Yield Strength

Magnesium aluminum alloy (MB15) offers a 2x strength-to-weight advantage over pure aluminum:

Load Resistance: Unlike standard aluminum rulers that bend under 50kg/mm², our rulers withstand 110kg/mm²—ideal for supporting 200kg+ workpieces during CNC machine bed calibration or textile loom installation. This prevents the 0.5mm/m sag common in weaker materials, ensuring parallelism stays within ±0.02mm/m (Grade 1 precision).

Thermal Stability: The alloy’s low coefficient of thermal expansion (21.5×10⁻⁶/°C) maintains accuracy across 10°C–40°C temperature swings, critical for outdoor construction or unheated workshops where steel rulers expand/contract unpredictably.

2. Applications Where Deformation Is Not an Option

Storaen’s magnesium aluminum parallel ruler excels in high-stakes scenarios:

CNC Machine Alignment: A 3000mm ruler with 110kg/mm² strength supports laser alignment tools during bed rail installation, ensuring 0.01mm/m parallelism for precision machining of automotive transmission cases—eliminating vibration-induced tool wear.

Textile Machinery Calibration: In loom setup, the ruler’s rigidity prevents sag when spanning 2000mm between guide rollers, maintaining ±0.05mm thread path alignment and reducing fabric defects by 30%.

Heavy Equipment Inspection: For mining machinery track alignment, the ruler’s anti-deformation design withstands accidental impacts (e.g., 5kg dropped tools) without permanent bend—unlike plastic or low-grade aluminum alternatives that require frequent replacement.

3. Design Advantages for Durability & Usability

Lightweight Rigidity: At just 3kg/m (30% lighter than steel), a 3m ruler weighs only 9kg, enabling one-person handling for elevated inspections (e.g., overhead conveyor rails) without fatigue—a key benefit for parallel ruler use in hard-to-reach areas.

Surface Protection: A 20μm anodized coating resists corrosion from coolant, oil, and humidity, extending service life by 2x compared to uncoated aluminum rulers—no need for regular anti-rust treatments.

Precision Grades: Choose Grade 1 (±0.02mm/m parallelism) for general industry or Grade 2 (±0.05mm/m) for layout tasks, both verified via laser interferometry to meet ISO 1101 standards.

4. Storaen’s Commitment to Value

Competitive Parallel Ruler Price: Starting at $299 for 500mm models, our magnesium aluminum rulers offer 3x the lifespan of generic steel tools, delivering lower total cost of ownership—especially for bulk orders in construction or manufacturing fleets.

Custom Solutions: Need a 6000mm ruler with reinforced end caps for heavy lifting? Our OEM team provides bespoke designs in 4–6 weeks, ensuring optimal load distribution for your unique parallel ruler use cases.

Warranty & Support: Backed by a 1-year warranty against deformation or coating failure, plus free calibration certificates for traceable accuracy—essential for quality audits in ISO 9001-certified facilities.

Don’t let deformation risks compromise your measurements. Storaen’s magnesium aluminum parallel ruler, with 110kg/mm² yield strength and lightweight durability, sets a new standard for industrial alignment. Whether for sale as a standalone tool or integrated into custom fixtures, our rulers ensure precision stays true under load, temperature shifts, and daily wear—making them the smart choice for professionals who demand reliability without compromise. Explore our parallel rulers for sale today and experience the Storaen difference in anti-deformation engineering.

How to Choose a Parallel Ruler: Size & Precision Grade Guide

Selecting the right parallel ruler is critical for accurate alignment and measurement in industrial applications. Whether for CNC machine calibration, textile loom setup, or heavy equipment inspection, the choice hinges on two key factors: size and precision grade—with material, durability, and cost playing supporting roles. Here’s your step-by-step guide to navigating these decisions, featuring Storaen’s engineered solutions that balance performance and value in parallel rulers for sale.

1. Size Selection: Match the Task at Hand

Choose a ruler length that suits your workpiece and parallel ruler use:

Small-Scale Tasks (≤1000mm):

500–1000mm rulers work for bench-top inspections, like verifying small machine components or electronic part alignment. Storaen’s aluminum alloy models (starting at $299) offer lightweight handling (1.5kg for 1000mm) without compromising rigidity, ideal for prototyping or low-load environments.

Mid-Range Applications (1000–3000mm):

1500–3000mm rulers are standard for CNC machine beds and textile machinery. Our magnesium aluminum parallel ruler (3kg/m weight, 110kg/mm² yield strength) spans 2000mm while resisting sag under 100kg loads, ensuring ±0.02mm/m parallelism for automotive part machining.

Large-Scale Projects (≥3000mm):

For industrial construction or aerospace assembly, 4000–6000mm rulers with reinforced ribs (available via Storaen’s OEM service) distribute weight evenly, enabling one-person use for overhead conveyor alignment without flexing.

2. Precision Grade: Align with Tolerance Requirements

Select based on your industry’s straightness and parallelism standards:

Grade 1 (±0.02mm/m):

Ideal for precision machining (e.g., aerospace components, medical device parts) where deviations over 20μm/m cause functional failures. Storaen’s Grade 1 rulers undergo laser interferometry calibration, meeting ISO 1101 and ASME B89.5.2 for traceable accuracy.

Grade 2 (±0.05mm/m):

Suits general industrial tasks like textile loom thread path setup or heavy equipment track alignment, balancing cost ($499 for 2000mm) and performance to reduce fabric defects or machinery vibration.

Grade 3 (±0.1mm/m):

Best for layout marking and rough alignment in construction or prototyping, where absolute precision is less critical but durability (anodized aluminum coating) and value matter most.

3. Material & Cost: Balance Rigidity, Weight, and Budget

Magnesium Aluminum Alloy:

30% lighter than steel, with 110kg/mm² yield strength for anti-deformation—perfect for aluminum rulers needing to withstand heavy loads without bending. Priced 20% higher than steel but offering 3x lifespan, ideal for high-stakes parallel ruler use.

Carbon Steel:

Heavy-duty and budget-friendly ($350 for 1000mm), suitable for occasional use or non-critical alignment in harsh workshops, though heavier (4kg for 1000mm) and prone to rust without regular maintenance.

4. Storaen’s Expert Recommendations

For CNC Machining: Pair a 2000mm magnesium aluminum parallel ruler (Grade 1, $899) with our laser alignment kit for ±0.01mm/m accuracy, minimizing tool wear and scrap rates.

For Textile Industry: A 1500mm anodized aluminum ruler (Grade 2, $599) ensures consistent thread path alignment, backed by a 1-year warranty against coating failure.

Custom Solutions: Need a 5000mm ruler with metric/imperial dual scales? Our team delivers bespoke designs in 4–6 weeks, optimizing for your unique parallel ruler use cases.

Choosing the right parallel ruler doesn’t have to be complex—prioritize size for your workpiece, precision for your tolerance needs, and material for your environment, then trust Storaen’s engineered solutions to deliver reliability at competitive parallel ruler price points. Explore our parallel rulers for sale today, and equip your workshop with tools designed to measure up to the toughest industrial challenges.

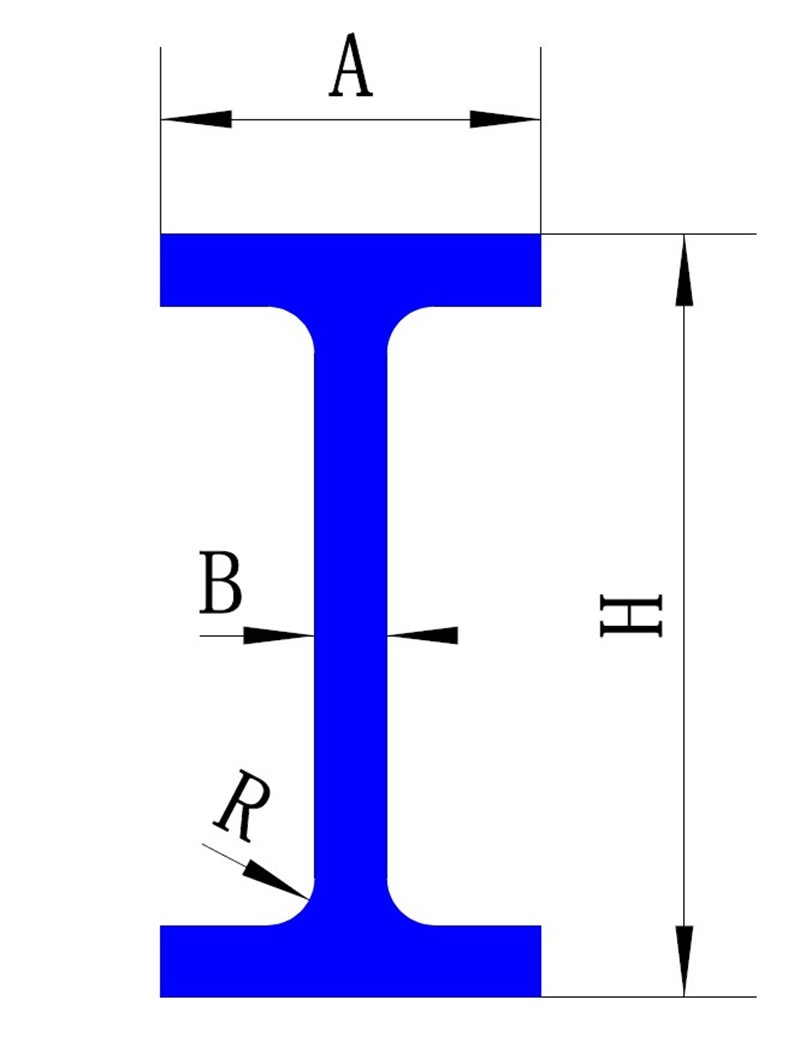

Produkta Detala Desegno

Produktaj priskriboj de la provizanto

Preciza Regulo de Aluminio Magnezia Alojo:

Paralela Regulo de Aluminia Magnezia Alojo estas uzata por inspektado de laborpecoj, mezurado, markado, ekipaĵo-instalado kaj industria konstrua projekto.

* Facila Stokado: povas pendanta aŭ horizontala lokigo, ne influos ĝian rektecon kaj paralelecon pro soletempa lokigo.

* Ne Facile Rustigi: ne uzu oleitan dum uzado, se ne estas uzata dum longa tempo, apliku maldikan tavolon da industria oleo kaj poste konservu.

* Pakado: lamenligna skatolo estas kutime uzata; bona pakaĵo ankaŭ haveblas.

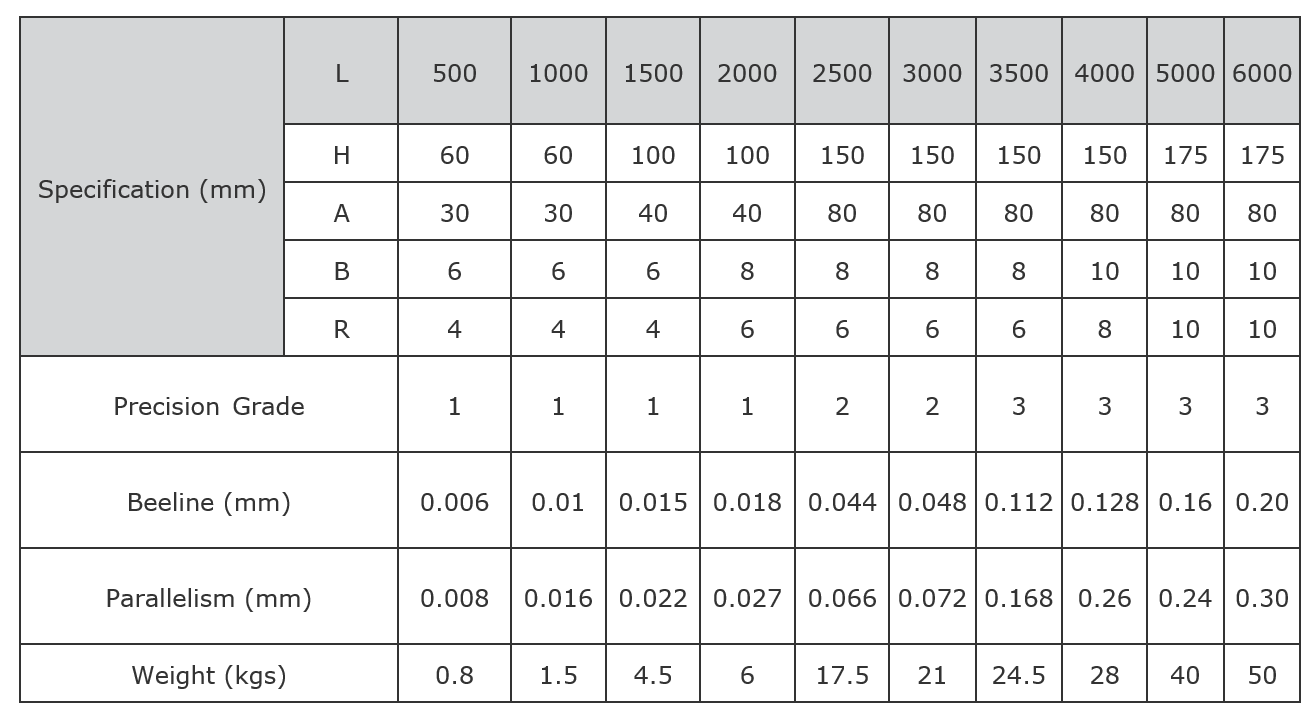

Teknika Specifo de Aluminia Magnezia Alojo

Preciza Regulo:

|

Specifo (mm) |

L |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

3500 |

4000 |

|

H |

60 |

60 |

100 |

100 |

150 |

150 |

150 |

150 |

|

|

A |

30 |

30 |

40 |

40 |

80 |

80 |

80 |

80 |

|

|

B |

6 |

6 |

6 |

8 |

8 |

8 |

8 |

10 |

|

|

R |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

8 |

|

|

Precizeca Grado |

1 |

1 |

1 |

1 |

2 |

2 |

3 |

3 |

|

|

Malalta (mm) |

0.006 |

0.01 |

0.015 |

0.018 |

0.044 |

0.048 |

0.112 |

0.128 |

|

|

Paralelismo (mm) |

0.008 |

0.016 |

0.022 |

0.027 |

0.066 |

0.072 |

0.168 |

0.26 |

|

|

Pezo (kgs) |

0.8 |

1.5 |

4.5 |

6 |

17.5 |

21 |

24.5 |

28 |

|

Rilata PRODUTOJ

RELACIAJ NOVAĴOJ

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.