Optika Komponita Bilda Nivelo

Priskribo de la produkto

- 1.Apliko

La optika kunmetita bildnivelo estas vaste uzata en mezurado de la gradientoj de plata surfaco kaj cilindra surfaco al horizontala direkto; La ebeneco kaj rekteco de glitvojo aŭ bazo de maŝinilo aŭ optika mekanika instrumento same kiel la ĝusteco de instalo de pozicio de ekipaĵo.

- 2.Teknikaj datumoj

(1) ĉiu diplomiĝa valoro: ...0.01mm/m

(2) maksimuma mezurado: ...0~10mm/m

(3) poŝmono: ...1mm/ene de unu metro... 0.01mm/m

Ene de plena mezurintervalo... 0.02mm/m

(4) ebena devio sur laborsurfaco...0.0003mm/m

(5) ĉiu diplomiĝa valoro de la nivelo de spirito...0.1mm/m

(6) laboranta surfaco (LW): ...165 48mm

(7) neta pezo de la instrumento: ...2kgs.

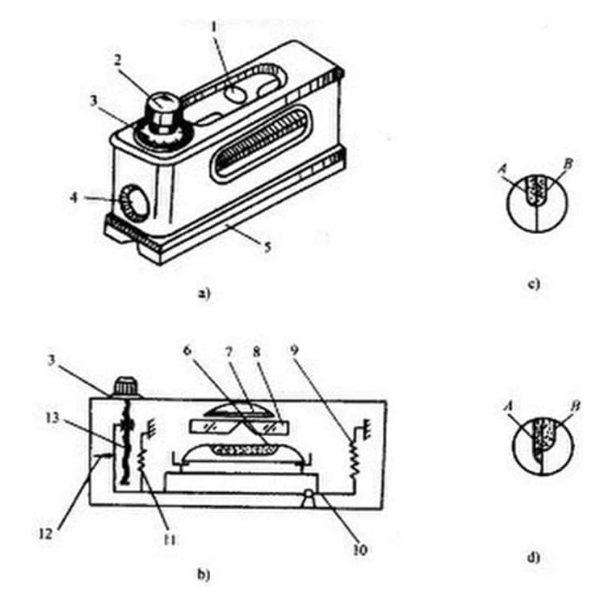

- 3. Strukturo de la instrumento:

La komponita bilda nivelo ĉefe konsistas el la sekvaj partoj kiel mikroĝustiga ŝraŭbo, nukso, gradigita disko, spiritonivelo, prismo, lupeo, levilo kaj bazo kun simpla kaj v laborsurfaco.

- 4. Funkcia principo:

La komponita bildnivelo uzas prismon por akiri la aervezikojn en la spiritnivela komponaĵo kaj pligrandigita por plibonigi legado-precizecon kaj uzas levilon kaj mikroŝraŭban elsendan sistemon por plibonigi legan sentemon. Sekve se la laborpeco kun gradiento de 0.01mm/m, ĝi povas esti precize legita en la kunmetita bildnivelo (la spiritnivelo en la kunmetita bildnivelo ĉefe ludas la rolon de indikado de nulo).

- 5. Operacia metodo:

Metu la kunmetitan bildnivelon sur la laborsurfacon de la mezura laborpeco kaj la gradiento de la mezura laborpeco kaŭzas nekoincidadon de la stupaj aerovezikbildoj; Rotaciu la gradigitan diskon ĝis la bildoj de la bobeloj koincidas kaj tuj povas ricevi legadon. La fakta gradiento de la mezura laborpeco povas esti kalkulita per la sekva formulo:

Fakta gradiento=gradienta valoro Fulcrumdistanco Diskolegado

Vulpo ekzemplo: Diskolegado: 5 gradientoj; Ĉar ĉi tiu kunmetita bildnivelo estas konforma kun sia gradientvaloro kaj fulcrodistanco, tio estas gradientvaloro: 0.01mm/m kaj fulcrodistanco: 165mm.

Do: Fakta gradiento=165mm 5 0.01/1000=0.00825mm

- 6.Avizo pri operacio:

(1) antaŭ uzo, purigu la olean polvon per benzino kaj poste purigu per sorba gazo.

(2) Temperaturŝanĝo havas grandan influon sur instrumento kaj tial ĝi devas esti apartigita per varmofonto por eviti eraron.

(3) Dum mezurado, turnu la gradigitan diskon ĝis la bildoj de la bobeloj de trena aero tute koincidas kaj tiam la legaĵoj en ambaŭ pozitivaj kaj negativaj direktoj povas esti prenitaj.

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5) Post laboro, la laborsurfaco de la instrumento devas esti purigita kaj kovrita per senacida, anhidra, kontraŭrusta oleo kaj kontraŭrusta papero; Metu ĝin en lignan skatolon kaj poste konservu ĝin en pura seka loko.

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

Produkta Parametro

Teknikaj parametroj

- Plata valoro ciferdisko 0,01 mm/m

- Mezura gamo 0-10 milimetroj/metro

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- Benko-plateco devio de 0.003mm

- Normo de amasiĝo de ĉela valoro 0,1 milimetroj/metro

- Oficeja skribotablo grandeco 165 x 48 milimetroj

- Neta pezo 2,2 kilogramoj

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

Rilata PRODUTOJ

RELACIAJ NOVAĴOJ

Precision Manufacturing with Advanced Spline Gauge Design

As a leading wholesale supplier in the precision measurement industry, Storaen (Cangzhou) International Trading Co. understands the critical role that Spline Gauges play in ensuring manufacturing accuracy.

Industrial-Grade Calibrated Pin Gauges for Exact Measurements

For precision-driven manufacturers, our Calibrated Pin Gauges deliver unmatched accuracy in dimensional verification.

Industrial Filtration Systems Depend on Quality Filter DN50 Solutions

In modern industrial operations, effective filtration plays a vital role in protecting equipment and ensuring smooth processes.