dec . 20, 2024 01:43 Back to list

Understanding the Functionality of Piston-Type Check Valves in Fluid Systems

Understanding Piston Type Check Valves Function, Design, and Applications

Piston type check valves are critical components in various fluid and gas systems, ensuring unidirectional flow while preventing backflow. These valves are widely used in industries like oil and gas, water treatment, and manufacturing due to their reliability and efficiency in maintaining system integrity. In this article, we will explore the fundamental aspects of piston type check valves, including their design, operation, and applications.

Design and Working Principle

The basic structure of a piston type check valve includes a cylindrical body, a piston, and a sealing mechanism. When fluid flows through the valve in the designated direction, the pressure differential pushes the piston upward, allowing the fluid to pass through. This action simultaneously compresses a spring that is positioned behind the piston. As long as the fluid is flowing in the intended direction, the valve remains open, facilitating smooth flow.

Conversely, when there is a reduction or reversal in flow, the spring force, combined with the pressure from the fluid, pushes the piston back into a seated position, creating a tight seal. This effectively prevents backflow, protecting downstream equipment and maintaining system pressure. The simplicity of the piston design provides both durability and ease of maintenance, making these valves highly preferred in critical applications.

Advantages of Piston Type Check Valves

One of the significant advantages of piston type check valves is their ability to handle high-pressure systems. They can withstand considerable pressure differentials while providing a secure seal, making them ideal for industrial applications where pressure stability is crucial. Additionally, their design minimizes the chance of interference with fluid flow, thereby reducing energy losses and enhancing system efficiency.

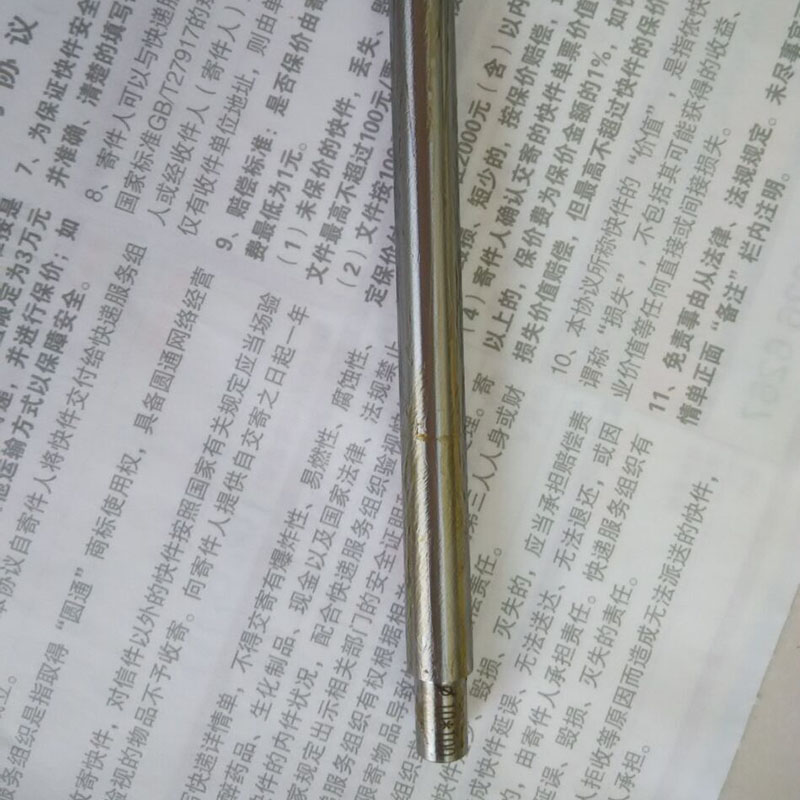

piston type check valve

Another benefit is their response time. Piston type check valves typically react quickly to changes in flow direction, safeguarding the system against potential damage caused by backflow. This rapid action is particularly important in systems involving pumps and compressors, where unregulated backflow can lead to catastrophic failures.

Applications in Various Industries

Piston type check valves find extensive applications across a spectrum of industries. In the oil and gas sector, they are used in pipelines to prevent backflow and protect piping systems from surges and pressure fluctuations. Similarly, in water treatment facilities, these valves play a vital role in ensuring that contaminants do not re-enter clean water lines, thus safeguarding public health.

Moreover, the manufacturing and chemical processing industries rely on piston type check valves to maintain the integrity of fluid systems. In applications where corrosive or hazardous materials are handled, these valves offer robust protection against leaks and backflow, further enhancing operational safety and equipment longevity.

Maintenance and Considerations

Despite their durability, regular maintenance of piston type check valves is essential to ensure optimal performance. It includes routine inspections for wear on the piston and seals, as well as any build-up of debris that could impede the valve's operation. Operators should also consider the compatibility of valve materials with the fluids being transported, particularly when dealing with aggressive chemicals.

In conclusion, piston type check valves are indispensable components in various applications that require reliable fluid flow control. Their design, efficiency, and quick response to changes in flow direction make them a preferred choice in many industrial settings. By understanding their function and maintenance requirements, operators can ensure the longevity and reliability of their systems, thereby safeguarding operations and protecting investments. As industries continue to evolve, the role of valve technology, particularly piston type check valves, remains pivotal in achieving operational excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS