sep . 11, 2024 12:34 Back to list

Precision Bore Snap Gauge - Accurate Measurement Tools for Industrial Applications

Understanding Bore Snap Gauges An Essential Tool in Modern Engineering

In the realm of precision engineering, the importance of accurate measurements cannot be overstated. One of the key instruments employed for achieving precise internal measurements in cylindrical components is the bore snap gauge. This article will explore the bore snap gauge's design, application, and significance in various industries.

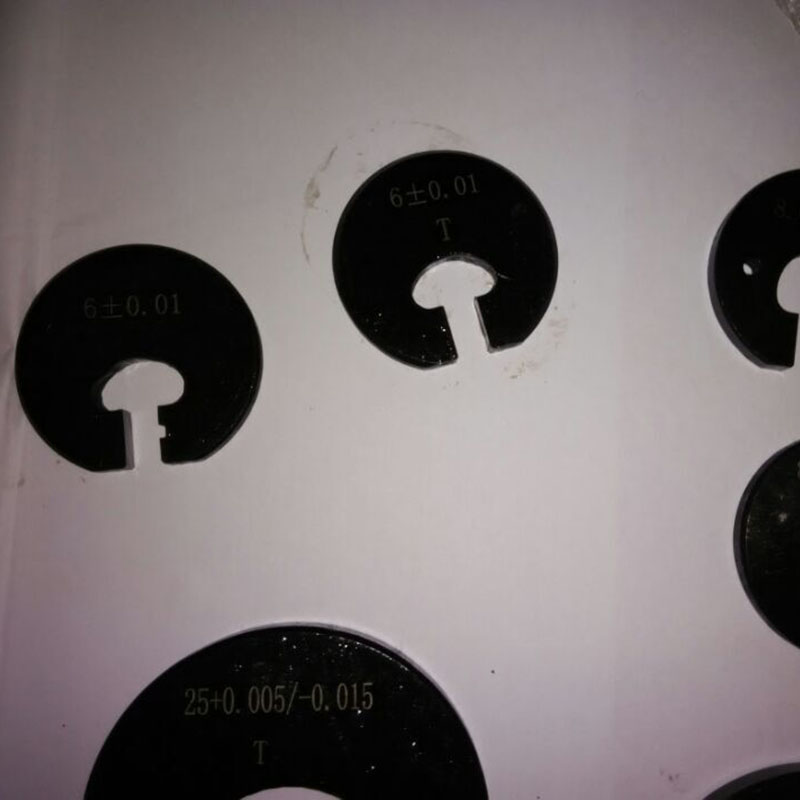

A bore snap gauge is a specialized tool used to measure the internal diameters of holes, pipes, and other cylindrical sections. Its design typically features two arms, one that moves and one that is fixed. The movable arm has a contact point that expands to touch the inner surface of the bore, while the fixed arm provides a reference point for measurement. This device allows for instantaneous readings, making it invaluable for quality control processes in manufacturing.

The functionality of a bore snap gauge lies in its ability to provide quick and accurate measurements without requiring extensive setup time. The tool can be easily inserted into the bore, and upon snapping the arms together, it effectively captures the internal dimensions. This of course has significant implications for production efficiency, reducing downtime related to measurement processes, and facilitating rapid inspection cycles.

bore snap gauge

In terms of industry application, bore snap gauges are used across various sectors, including automotive, aerospace, and general engineering. For instance, in the automotive industry, these gauges are crucial for inspecting engine components, such as cylinders and pistons, ensuring they meet strict tolerances that safeguard performance and reliability. Similarly, in aerospace, where precision is paramount, bore snap gauges help manufacturers adhere to rigorous standards that ensure the safety and functionality of aircraft components.

One of the defining attributes of bore snap gauges is their versatility. They come in various sizes and designs, catering to different bore dimensions and depths. Digital versions are also available, providing electronic readouts for improved accuracy and data management. Such advancements in technology have broadened the scope of their application, allowing for more sophisticated measurement techniques.

Despite their simplicity, proper usage and calibration of bore snap gauges are critical. Regular calibration ensures that the gauge provides reliable measurements, which is essential for maintaining quality standards. Operators must also be trained in the correct technique to avoid damaging the tool or the workpiece.

In conclusion, bore snap gauges represent a pivotal component of the engineering toolkit, providing a blend of simplicity and precision. As industries continue to push the boundaries of manufacturing capabilities, these gauges will remain indispensable in ensuring quality, reliability, and accuracy. With their ease of use and adaptability across various applications, bore snap gauges are not just tools but are integral to the continuous improvement of manufacturing practices. Whether measuring the diameter of an engine cylinder or verifying the dimensions of intricate components, bore snap gauges exemplify the intersection of tradition and technology in the pursuit of excellence in engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS