Δεκ . 01, 2024 17:17 Back to list

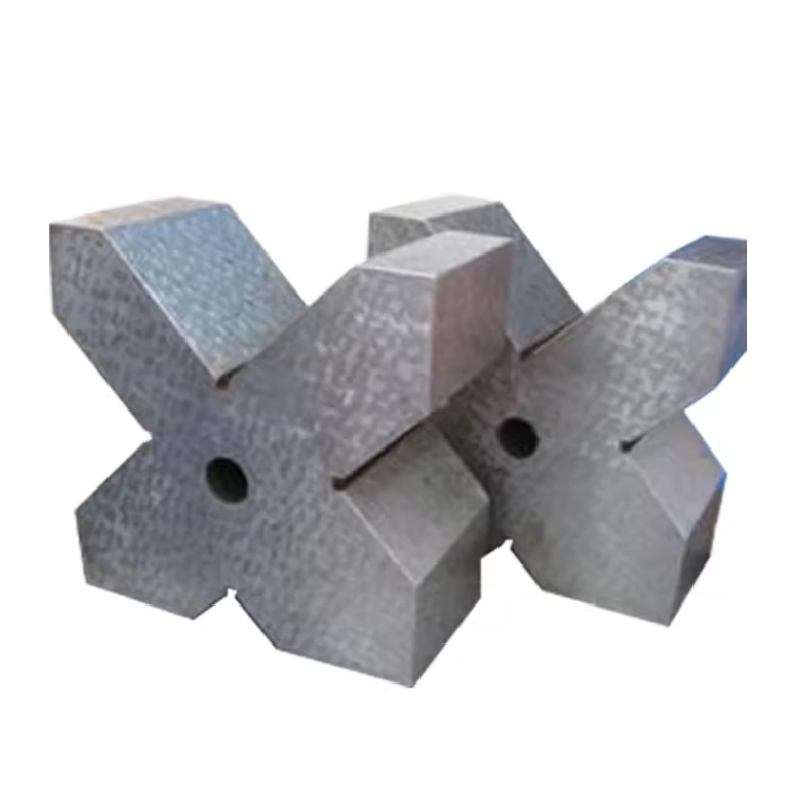

metal fabrication protractor

The Importance of Metal Fabrication Protractors in Precision Engineering

In the world of metal fabrication and engineering, accuracy is paramount. A small error in measurements can lead to significant complications in the final product. This is where tools like the metal fabrication protractor come into play, serving as essential instruments that enhance precision in various metalworking tasks.

Understanding the Metal Fabrication Protractor

A metal fabrication protractor is a specialized tool used to measure angles with high precision. Unlike traditional protractors, which are often made from plastic, metal protractors are built to withstand the rigors of a fabrication environment. They are typically made from durable materials such as stainless steel or aluminum, ensuring longevity and resistance to wear and tear.

The primary function of a metal fabrication protractor is to provide accurate angle measurements. It usually comes with a swivel arm that allows users to set and read angles easily, often featuring both metric and imperial measurements. With some models, users can also find additional features, such as built-in levels or laser measurements, which further enhance the tool's functionality.

Key Benefits of Using Metal Fabrication Protractors

1. Precision Measurement One of the most significant advantages of using a metal protractor is its ability to deliver precise angle measurements. This precision is critical in metal fabrication, where any deviation can lead to misalignment, affecting the integrity and performance of the final product.

2. Durability and Longevity Metal protractors are designed for heavy-duty use in various environments. They are resistant to corrosion, which is a common issue in metalworking shops, ensuring that they retain their accuracy over time.

3. Ease of Use Many metal protractors are designed with user-friendliness in mind. The swivel arm and clear measurement markings make it easy for both novice and experienced fabricators to take accurate readings without extensive training.

4. Versatility Metal fabrication protractors can be used in a range of applications beyond just measuring angles. They are also useful for layout work, scribing lines, and even checking the squareness of cuts. This versatility makes them indispensable in a fabricator’s toolkit.

metal fabrication protractor

5. Enhanced Safety Accurate measurements can lead to safer fabrication processes. A correctly cut piece of metal is less likely to cause accidents or structural failures. By using a metal fabrication protractor, fabricators can minimize risks associated with improper measurements.

Applications in Metal Fabrication

Metal fabrication protractors are utilized across various industries, including construction, automotive, aerospace, and manufacturing. In the construction sector, for instance, these tools are essential for ensuring that steel beams and other metal components are angled correctly, which is critical for the overall stability of structures.

In the automotive industry, manufacturers rely on protractors to create precisely angled parts that fit together seamlessly, ensuring that vehicles are safe and reliable. Aerospace engineers also use these tools to guarantee that components meet strict regulations and standards, as even the slightest miscalculation can have dire consequences.

Best Practices for Using Metal Fabrication Protractors

To maximize the effectiveness of a metal fabrication protractor, users should adhere to several best practices

- Keep it Clean Regularly clean the protractor to remove metal shavings and debris that could affect its accuracy. - Store Properly When not in use, store the protractor in a protective case to avoid damage. - Calibrate Regularly Check the calibration periodically, especially if the protractor has been subjected to rough handling or extreme conditions. - Use with Care When measuring, ensure that the protractor is stable and that the arm is set firmly against the workpiece.

Conclusion

In summary, the metal fabrication protractor is an indispensable tool in the world of precision engineering and metalworking. Its ability to provide accurate measurements while remaining durable and user-friendly enhances the fabrication process, leading to improved quality and safety in various applications. By adopting best practices and understanding its importance, fabricators can ensure they are equipped to meet the demands of their trade with confidence and precision. As technology advances and methodologies evolve, the metal fabrication protractor will remain a fundamental element in the quest for accuracy in metal fabrication.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS