Δεκ . 11, 2024 18:14 Back to list

control valve price

Understanding Control Valve Prices Factors and Insights

Control valves are critical components in various industrial processes, playing a significant role in regulating flow, pressure, temperature, and levels within piping systems. The price of control valves can vary significantly based on numerous factors, making it essential for businesses to understand what influences these costs to make informed purchasing decisions.

Key Factors Affecting Control Valve Prices

1. Type of Control Valve The type of control valve has a direct impact on its price. Common types include globe valves, ball valves, butterfly valves, and gate valves. Each type serves different functions and is designed for specific applications. For instance, ball valves are typically more expensive than gate valves due to their complexity and the precision required in their design and manufacturing.

2. Material of Construction The materials used in manufacturing control valves significantly influence their cost. Valves are made from various materials, including stainless steel, carbon steel, brass, and plastic. Stainless steel valves, known for their corrosion resistance and durability, tend to be more expensive than their carbon steel counterparts. Additionally, exotic materials like Hastelloy or Monel can further drive up costs due to their rarity and specialized applications.

3. Size and Pressure Rating The size of the control valve and its pressure rating are crucial determinants of price. Larger valves or those designed to operate at higher pressures typically come at a premium. This is due to the increased amount of material needed for construction and the higher testing and quality assurance standards required to ensure safe operation under extreme conditions.

control valve price

4. Actuation Method Control valves can be actuated manually, pneumatically, electrically, or hydraulically. Pneumatic and electric actuators tend to increase the overall cost of the valve, given the complexities involved in their operation. Automated valves, which facilitate precise control and integration into modern industrial systems, often are priced higher due to their advanced technology.

5. Brand and Manufacturer Just as with many other products, the brand and manufacturer can significantly affect control valve prices. Established brands with a reputation for quality and reliability may price their products higher than lesser-known manufacturers. However, investing in a reputable brand can often lead to cost savings in the long run through reduced maintenance and improved efficiency.

6. Volume and Order Size Purchasing control valves in bulk can lead to substantial discounts. Many manufacturers offer price breaks for larger orders, and working with a supplier who can negotiate terms based on long-term contracts can further reduce costs.

7. Custom Features and Specifications Special features or customized specifications, such as specific pressure ratings, unique materials, or additional instrumentation, can significantly raise the price of control valves. Companies requiring valves suited to unique operational conditions should expect to pay more for these tailored solutions.

Conclusion

Understanding the factors that influence control valve prices is vital for businesses involved in industrial operations. By considering the type, material, size, actuation method, brand, order volume, and custom features, companies can make more cost-effective purchasing decisions. It's also important to conduct thorough market research and possibly consult with industry experts or suppliers to ensure that the chosen control valve not only fits the budget but also meets the operational needs effectively. By investing wisely in control valves, businesses can enhance their operational efficiency, reduce long-term costs, and ensure the smooth functioning of their processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

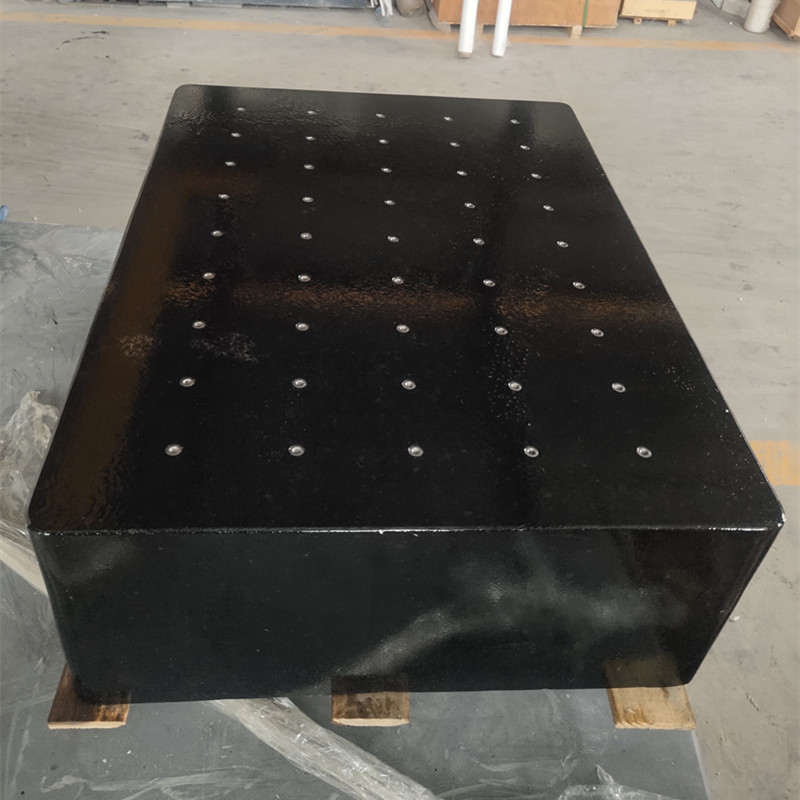

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS