Δεκ . 03, 2024 16:31 Back to list

China Butterfly Valve Manufacturer for Reliable Flow Control Solutions in Industrial Applications

China Butterfly Valve Factory An Overview of Innovation and Excellence

In recent years, the demand for high-quality industrial components has surged globally, and China has positioned itself as a leader in manufacturing various types of valves, including butterfly valves. Butterfly valves, known for their lightweight design and efficient performance, are critical in controlling the flow of liquids or gases in pipelines across various industries such as water supply, chemical processing, oil and gas, and many others. This article explores the evolution, manufacturing processes, quality standards, and competitive advantages of butterfly valve factories in China.

The Evolution of Butterfly Valves in China

Butterfly valves have been around for decades, but their design and manufacturing processes have significantly evolved. Chinese manufacturers have embraced modern technology and innovative practices to enhance the performance characteristics of butterfly valves. Initially, the focus was primarily on meeting domestic demands, but as the global market expanded, factories began to invest in advanced machinery and R&D to compete internationally.

China's butterfly valve production has greatly benefited from its vast resources and skilled workforce. The nation's ability to harness these advantages has not only increased production capacity but has also significantly reduced costs. Today, China exports a substantial volume of butterfly valves to markets around the world, solidifying its reputation as a manufacturing powerhouse.

Manufacturing Processes

The manufacturing process of butterfly valves in China involves several critical steps to ensure the production of high-quality, reliable products

1. Material Selection The choice of materials is vital for durability and performance. Chinese factories typically use high-grade stainless steel, ductile iron, and PVC, depending on the specific application and service conditions.

2. Precision Machining Advanced CNC (Computer Numerical Control) machinery allows for precise machining of valve components. This precision is essential for ensuring that the valve seals properly and operates efficiently.

3. Assembly and Testing After machining, the components are carefully assembled. Factories employ rigorous testing procedures, including pressure tests and flow tests, to ensure that each butterfly valve meets the required specifications and standards.

4. Quality Control Quality assurance is a top priority in Chinese factories. In-house testing laboratories and third-party inspections are commonly used to ensure that products adhere to international standards such as API, ANSI, and ISO.

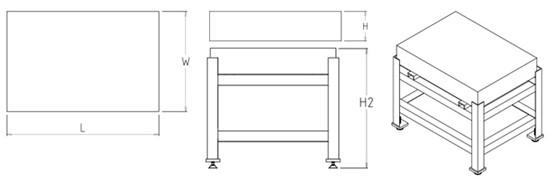

china butterfly valve factory

Quality Standards and Certifications

Chinese butterfly valve manufacturers adhere to a range of quality standards to maintain competitiveness in the global market. Many factories obtain certifications such as ISO 9001 for quality management systems, which illustrates their commitment to continuous improvement and customer satisfaction. Additionally, compliance with industry-specific standards like API 609 for valve design and manufacturing ensures that the products can withstand extreme conditions and perform reliably across various applications.

Competitive Advantages

Chinese butterfly valve factories have several competitive advantages, making them attractive to both domestic and international buyers. These include

1. Cost-effectiveness Competitive labor costs and access to raw materials allow Chinese manufacturers to produce butterfly valves at lower prices without compromising quality.

2. Rapid Production The ability to scale production quickly enables factories to meet large orders and tight deadlines, which is vital in industries that rely on just-in-time manufacturing.

3. Innovation and Technology Continuous investment in technology and innovation leads to the development of high-performance butterfly valves that cater to the evolving demands of modern industries.

4. Strong Supply Chain Proximity to essential suppliers and logistical infrastructure facilitates efficient operations and delivery processes, contributing to a seamless supply chain.

Conclusion

In summary, China’s butterfly valve factories exemplify innovation and excellence in the manufacturing sector. Their commitment to quality, cost-effectiveness, and rapid production positions them as key players in the global valve market. As industries continue to grow and evolve, the role of these manufacturers in supplying reliable, high-performance butterfly valves will remain essential. With a strong focus on quality and the adoption of advanced technologies, Chinese butterfly valve manufacturers are well-equipped to meet the ever-changing needs of the global market.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS