Οκτ . 31, 2024 18:04 Back to list

30 Percent Butterfly Valve Specifications and Applications Explained

Understanding the Role of 30% Butterfly Valves in Industrial Applications

Butterfly valves are critical components in various industrial processes, serving as a reliable means of regulating and controlling fluid flow. Among the many types of butterfly valves, the 30% butterfly valve stands out for its unique function and efficiency. This article delves into its design, operation, advantages, and applications.

Design and Operation

A butterfly valve is characterized by a rotating disc that controls the flow of fluid through a pipe. The 30% butterfly valve specifically refers to a valve that is engineered to open and control flow to approximately 30% of the full capacity. This design is particularly advantageous in processes that require a reliable means of throttling flow without completely shutting it off.

The operation of a 30% butterfly valve involves a spindle attached to the disc. When the handle or actuator is turned, the spindle rotates, causing the disc to pivot about a central axis. As the disc opens to a 30% angle, it allows for a controlled flow, maintaining pressure and reducing the risk of cavitation or turbulence in the system.

Advantages

One of the primary advantages of using a 30% butterfly valve is its efficiency. By allowing for a precise control of fluid flow, these valves minimize energy waste and optimize the overall operational effectiveness of the system. Additionally, the design of the butterfly valve provides a lower pressure drop compared to other types of valves, making it ideal for applications where energy conservation is a priority.

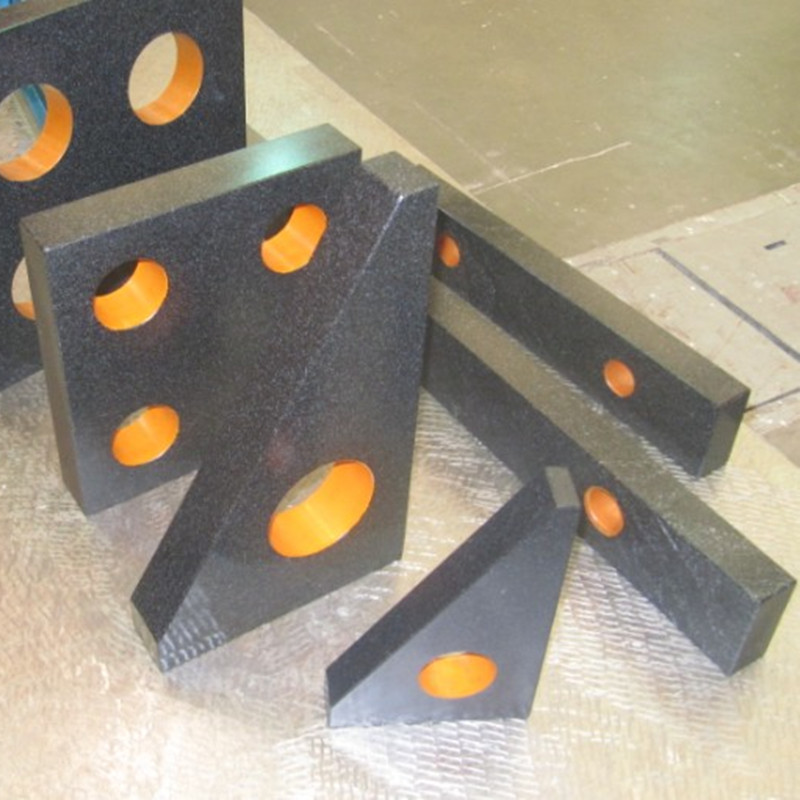

30 butterfly valve

Another significant benefit is the durability of butterfly valves. Constructed from robust materials such as stainless steel, cast iron, or plastic, they are resistant to wear and corrosion. This longevity leads to lower maintenance costs and reduced downtime, which is crucial for industrial applications where time is money.

Applications

The 30% butterfly valve finds its application across various sectors, including water treatment, chemical processing, food and beverage manufacturing, and oil and gas. In water treatment plants, these valves help regulate water flow efficiently, ensuring that treatment processes run smoothly and effectively. In chemical processing, they can control the flow of various fluids, minimizing the risk of backflow and potential contamination.

In the food and beverage industry, hygiene and safety are paramount. The 30% butterfly valve meets these demands by providing a reliable flow control solution that is easy to clean and maintain. Similarly, in the oil and gas sector, these valves ensure safe and efficient handling of resources, providing critical flow regulation in pipelines and storage facilities.

Conclusion

In summary, the 30% butterfly valve is an essential tool in various industrial applications, offering a combination of efficiency, durability, and precise flow control. Its design allows for significant energy savings while facilitating maintenance and operation. As industries continue to evolve, the adoption of such innovative solutions will be key to achieving greater efficiency and sustainability in fluid management. Whether in water treatment or chemical processing, the role of the 30% butterfly valve remains indispensable, ensuring that processes run smoothly and effectively.

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS