Dez . 29, 2024 20:22 Back to list

Welding Inspection Tools for Precision Measurement and Quality Assurance

The Importance of Welding Inspection Rulers in Quality Control

Welding is a fundamental process in various industries, including construction, automotive, aerospace, and manufacturing. Ensuring the integrity and quality of welded joints is crucial, as these connections must withstand various stresses and environmental factors. One of the critical tools used in the quality control of welding is the welding inspection ruler. This article explores the significance of welding inspection rulers, their types, and their role in maintaining high standards in welding operations.

What is a Welding Inspection Ruler?

A welding inspection ruler is a specialized tool designed to measure specific attributes of welds, such as size, depth, and profile. Typically made of durable materials like stainless steel or aluminum, these rulers come with various markings and features that facilitate accurate measurements. They are essential in assessing the quality of welds, ensuring that they meet predefined specifications and standards.

Types of Welding Inspection Rulers

1. Fillet Weld Gauges These rulers are specifically designed to measure the size of fillet welds. They often come with clearly marked slots or notches that indicate acceptable weld sizes. By using a fillet weld gauge, a welder or inspector can quickly determine whether a weld meets the required standards.

2. Bevel Protractors A bevel protractor is another type of inspection tool that allows for measuring angles, particularly in the preparation of edges for welding. Accurate angle measurements are critical as they influence the quality and strength of the weld.

3. Weld Penetration Gauges These rulers are used to check the depth of penetration in the weld. Proper penetration is essential for ensuring the strength of the welded joint. Insufficient penetration can lead to weak spots, compromising the structural integrity of the weld.

4. Weld Profile Gauges These gauges are used to examine the overall profile of a weld bead, including the height and width. Measuring these dimensions helps ensure that the weld conforms to the specified geometric requirements.

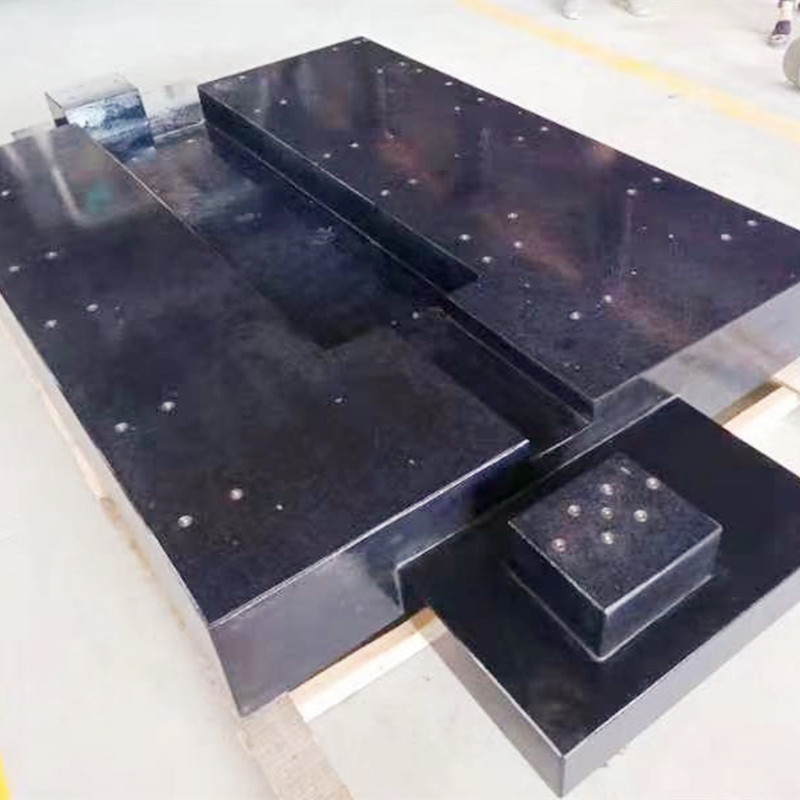

welding inspection ruler

The Role of Welding Inspection Rulers in Quality Control

Welding inspection rulers play a pivotal role in maintaining the quality of welding projects. Here are some key aspects of their importance

1. Ensuring Compliance with Standards Various standards, such as those from the American Welding Society (AWS) or the International Organization for Standardization (ISO), outline the required dimensions and characteristics for welds. Using welding inspection rulers ensures that welds comply with these standards, reducing the risk of failures.

2. Preventing Defects By facilitating accurate measurements, welding inspection rulers help identify defects early in the welding process. This proactive approach allows welders to make necessary adjustments, thereby preventing critical failures that could arise from poor welding practices.

3. Enhancing Safety The integrity of welded joints is crucial for the safety of structures and components. By using inspection rulers to verify the quality of welds, companies can ensure that their products are safe for use, ultimately protecting workers and end-users.

4. Streamlining Inspection Processes With the use of welding inspection rulers, the inspection process becomes more efficient and effective. Inspectors can quickly and accurately assess welds, leading to faster project completion times and reduced costs.

5. Documentation and Record Keeping Many industries require detailed records of inspections for regulatory compliance and quality assurance. Welding inspection rulers help create precise measurements that can be documented, ensuring that there is a clear record of weld quality over time.

Conclusion

Welding inspection rulers are invaluable tools in the welding industry, playing a crucial role in ensuring the quality and safety of welded joints. By using these rulers effectively, inspectors and welders can uphold high standards, prevent defects, and ensure compliance with relevant regulations. As industries continue to evolve, the importance of quality control tools like welding inspection rulers will only increase, cementing their role in the future of welding.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS