Okt . 19, 2024 05:22 Back to list

granite fabrication tilt table

Tilt Tables in Granite Fabrication An Essential Tool for Precision and Efficiency

In the world of granite fabrication, efficiency and precision are paramount. One of the most significant advancements in this field is the introduction of tilt tables. These specialized tables have revolutionized how granite slabs are handled, cut, and finished, leading to better outcomes and higher productivity for fabricators.

Tilt Tables in Granite Fabrication An Essential Tool for Precision and Efficiency

The primary advantage of a tilt table is its ability to adjust the angle of the granite slab without the need for additional equipment or labor. By simply tilting the surface, workers can achieve optimal positioning for cutting and polishing, reducing the strain involved in manual handling. This innovative equipment allows fabricators to work more effectively, enhancing both safety and speed. For example, when working on detailed edge profiles or intricate designs, a tilt table enables operators to have full access to the slab, improving accuracy while minimizing the risk of mistakes.

granite fabrication tilt table

Moreover, tilt tables enhance the overall workflow in a fabrication shop. Workers can easily rotate the granite slab to the most convenient position during different stages of production, from measurement to cutting and finishing. This not only streamlines the process but also reduces the time spent repositioning materials or setting up secondary equipment. The result is a significant gain in operational efficiency that can lead to quicker turnaround times for projects, which is crucial in a competitive market.

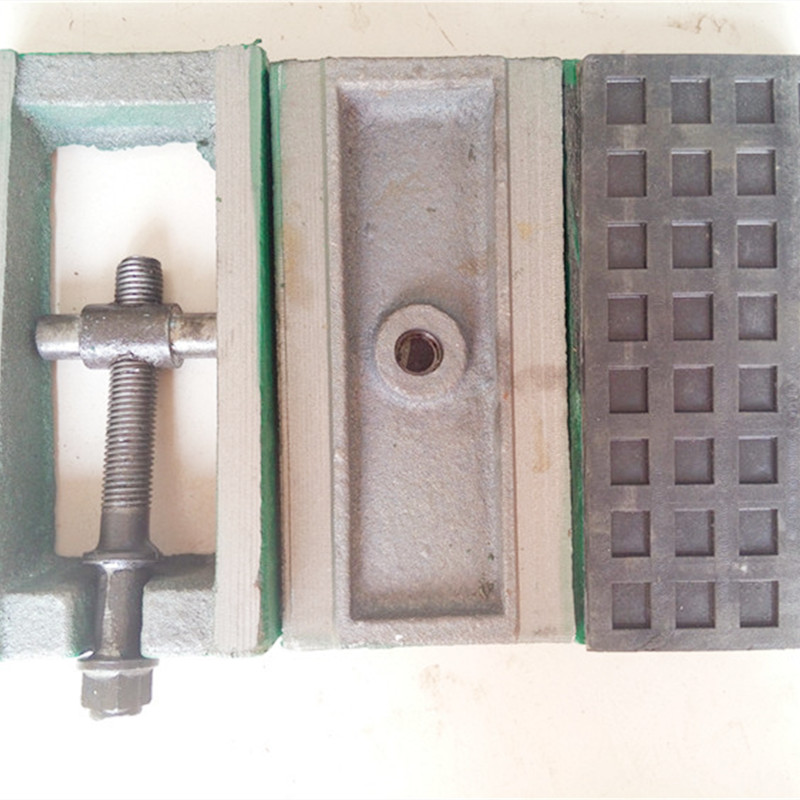

In terms of design, most tilt tables are constructed with durable materials to withstand the heavy weight of granite and other comparable stones. They often feature sturdy frames, reinforced surfaces, and adjustable locking systems to ensure safety during operation. Some advanced models even come equipped with hydraulic systems for effortless tilting and positioning. These features make tilt tables not just functional but also safe, allowing workers to focus on their craft without the constant worry of equipment failure or personal injury.

Beyond just improving efficiency and safety, tilt tables also contribute to higher-quality granite products. With enhanced access to all surfaces of the stone, fabricators can ensure that every inch is polished and cut to perfection. The ability to work from various angles allows for a level of detail and craftsmanship that is often unattainable with traditional methods.

In conclusion, the introduction of tilt tables in granite fabrication has marked a significant step forward in enhancing productivity, safety, and craftsmanship. These versatile tools allow for the efficient handling of heavy slabs while providing workers with the accessibility needed to perform intricate tasks. As the industry continues to advance, the tilt table remains a pivotal component in the modern granite shop, ensuring that fabricators can meet increasing demands without compromising on quality. For those in the business, investing in a tilt table is not just a matter of convenience; it's a strategic move towards achieving excellence in granite fabrication.

-

Welding Table Cast Iron Surface Finish GuideNewsJul.01,2025

-

Valve Types for Industrial ApplicationsNewsJul.01,2025

-

Types of Strainer for Industrial ApplicationsNewsJul.01,2025

-

Types of Bore Gauge for Precision MachiningNewsJul.01,2025

-

Safety Standards in Welding Fabrication Table Manufacturing ProcessesNewsJun.30,2025

-

Impact of Temperature Fluctuations on Ring Gauge AccuracyNewsJun.30,2025

Related PRODUCTS