Jun . 12, 2025 15:16 Zurück zur Liste

Energy Efficiency Innovations in Hydraulic Control Valves

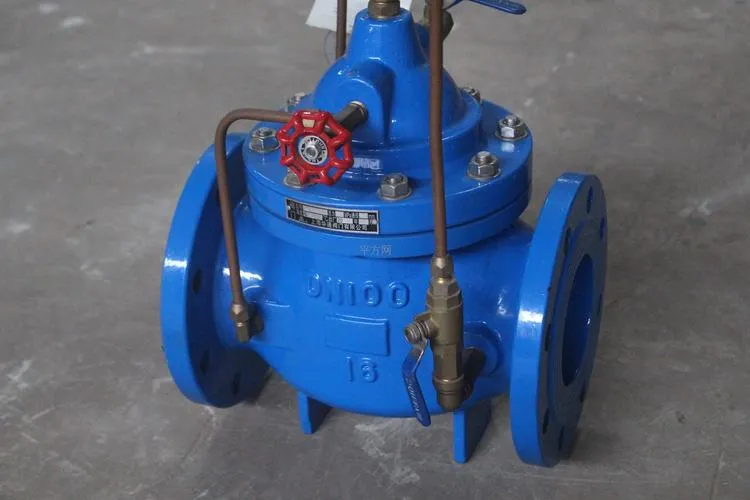

The global industrial landscape is increasingly prioritizing energy efficiency to reduce operational costs and environmental impact. Hydraulic systems, which power everything from manufacturing machinery to construction equipment, are a focal point for innovation. At the heart of these systems lie hydraulic control valves, critical components that regulate pressure, flow, and direction of hydraulic fluid. Recent advancements in pressure control valve types, flow control valve types, control valve technology, and flow control valve designs have significantly improved energy efficiency. This article explores these innovations, highlighting how they contribute to sustainable and cost-effective hydraulic operations.

Innovations in Pressure Control Valve Types for Energy Savings

Pressure control valve types are essential for maintaining system stability and preventing overloads. Traditional designs, such as relief valves and reducing valves, often consumed excess energy due to internal leakage or imprecise pressure regulation. Modern innovations address these inefficiencies through advanced materials and smart technologies.

Proportional pressure control valves, for instance, use electronic feedback systems to adjust pressure in real time. By integrating sensors and microprocessors, these valves minimize pressure spikes and ensure optimal performance across varying loads. This reduces energy waste caused by constant manual adjustments or overshooting pressure thresholds.

Another breakthrough is the development of low-leakage poppet and spool designs. These valves feature tighter tolerances and wear-resistant coatings, which reduce internal leakage by up to 30%. Combined with predictive maintenance algorithms, these pressure control valve types extend service life and maintain efficiency even in high-cycle applications.

Advancements in Flow Control Valve Types for Precision and Efficiency

Flow control valve types govern the rate of hydraulic fluid movement, directly impacting system responsiveness and energy use. Older designs, like simple throttle valves, often led to turbulence and heat generation, wasting energy. Newer innovations focus on precision and adaptability.

Pressure-compensated flow control valves are a prime example. These valves automatically adjust their orifice size based on system pressure, ensuring consistent flow rates despite load fluctuations. This eliminates the need for manual recalibration and reduces energy consumption by up to 20% in variable-speed applications.

Electro-hydraulic flow control valves represent another leap forward. By combining hydraulic mechanisms with electronic controls, these valves enable programmable flow profiles. For instance, they can ramp up flow during peak demand and reduce it during idle phases, aligning energy use with operational needs. Such flow control valve types are particularly valuable in mobile hydraulics, where battery-powered systems benefit from optimized power consumption.

Smart Technologies Revolutionizing Control Valve Systems

The evolution of control valve systems has been driven by the integration of IoT and machine learning. Modern valves are no longer passive components but active participants in system optimization.

Wireless sensors embedded in control valve assemblies monitor parameters like temperature, pressure, and vibration. This data is transmitted to centralized platforms, where AI algorithms predict maintenance needs and identify inefficiencies. For example, a valve nearing failure can be serviced before it causes downtime, preventing energy losses from emergency shutdowns.

Additionally, self-regulating control valve systems use real-time data to adjust their operation autonomously. In a hydraulic press, such valves can modulate pressure and flow during different stages of the pressing cycle, ensuring energy is used only when necessary. These innovations not only enhance efficiency but also reduce the carbon footprint of industrial operations.

Optimizing Flow Control Valve Designs for Sustainable Hydraulics

Flow control valve designs have undergone significant reengineering to align with sustainability goals. A key focus area is reducing fluid friction, which accounts for substantial energy losses in hydraulic circuits.

Laminar flow valves, featuring streamlined internal passages, minimize turbulence and pressure drops. By maintaining smooth fluid motion, these designs cut energy consumption by 15–25% compared to traditional turbulent flow designs. Similarly, valves with variable orifice technology adapt their geometry to match flow requirements, further curbing energy waste.

Another innovation is the use of lightweight composite materials. These materials reduce the inertia of moving parts within flow control valve mechanisms, enabling faster response times and lower actuation energy. When paired with regenerative hydraulic circuits, which recapture energy from deceleration phases, these valves contribute to closed-loop energy efficiency.

FAQs About Energy-Efficient Control Valves

How do pressure control valve types improve energy efficiency in hydraulic systems?

Modern pressure control valve types leverage electronic feedback and precision engineering to maintain optimal pressure levels with minimal leakage. This reduces energy waste caused by over-pressurization or frequent adjustments.

What innovations are present in flow control valve types to reduce energy consumption?

Flow control valve types now incorporate pressure compensation and electro-hydraulic controls, which dynamically adjust flow rates to match demand. This eliminates unnecessary fluid movement and lowers heat generation.

How does the control valve integrate with smart manufacturing systems?

Advanced control valve systems use embedded sensors and IoT connectivity to share real-time data with central controllers. This enables predictive maintenance and autonomous adjustments, optimizing energy use.

What role do flow control valve designs play in sustainable hydraulics?

Innovative flow control valve designs, such as laminar flow and variable orifice mechanisms, reduce fluid friction and adapt to operational needs, cutting energy consumption by up to 25%.

Can existing systems be retrofitted with energy-efficient control valve solutions?

Yes. Many modern control valve technologies are compatible with legacy systems, allowing manufacturers to upgrade without replacing entire hydraulic setups.

Energy efficiency in hydraulic systems is no longer a luxury but a necessity. Innovations in pressure control valve types, flow control valve types, control valve intelligence, and flow control valve designs are driving this transformation. By adopting these technologies, industries can achieve significant cost savings, reduce environmental impact, and meet stringent regulatory standards. As hydraulic systems continue to evolve, the focus on sustainability and precision will remain paramount, ensuring these critical components operate at peak efficiency for years to come.

-

Precision Manufacturing with Advanced Spline Gauge DesignNachrichtJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNachrichtJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNachrichtJul.31,2025

-

High-Performance Gate Valve WholesaleNachrichtJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNachrichtJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNachrichtJul.31,2025

Verwandte PRODUKTE