Nov . 05, 2024 18:04 Back to list

custom built welding tables

Custom Built Welding Tables The Cornerstone of Welding Efficiency

In the world of metal fabrication, precision and efficiency are paramount. Whether you're a seasoned welder or just starting, one of the most crucial elements of achieving high-quality welds is having the right workspace. Custom built welding tables have emerged as an essential component in the arsenal of tools for both professional and hobbyist welders. These tables provide a tailored solution to meet the unique needs of various welding projects, enhancing productivity and guaranteeing superior results.

The Importance of a Welding Table

A welding table serves as a stable platform for holding workpieces in place during the welding process. The stability and height of the table can significantly affect the ease of welding. A poorly designed or unsuitable table can lead to uncomfortable working conditions, inefficient workflows, and, ultimately, compromised weld quality. Thus, the development of custom-built welding tables allows welders to optimize their workspace according to their specific requirements.

Features of Custom Built Welding Tables

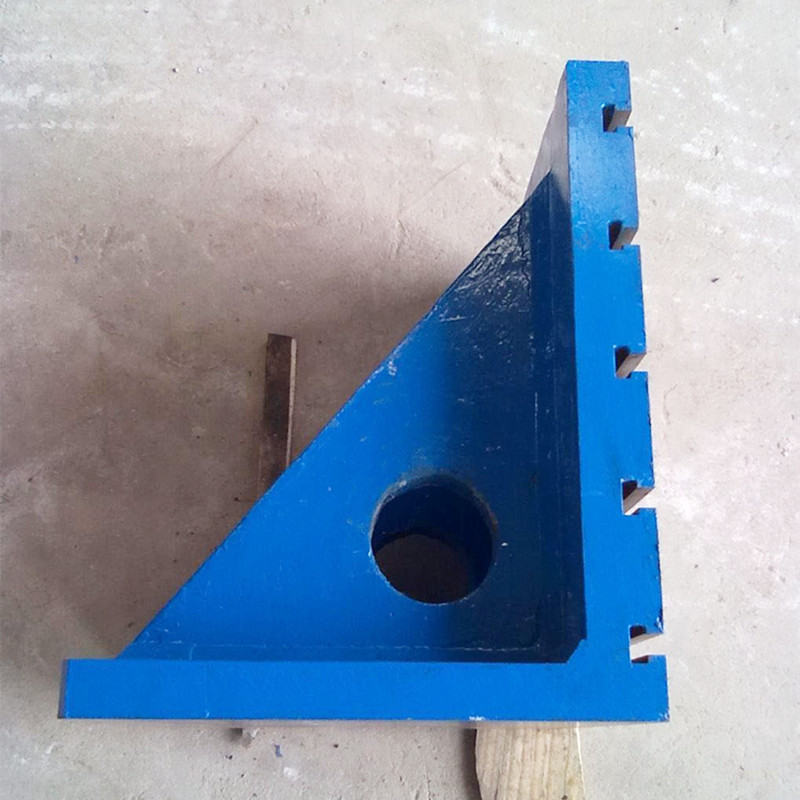

1. Material Choice The foundation of any welding table is its material. Heavy-duty steel is a common choice due to its durability and resistance to warping under high temperatures. Some custom tables also incorporate a top layer of aluminum or other materials to suit different welding techniques and to prevent contamination of materials.

2. Dimensions and Size Custom welding tables can be designed to fit specific spatial constraints and project sizes. This adaptability means that welders can choose dimensions that best suit their needs, whether it's a compact table for small projects or a larger workspace for substantial fabrications.

3. Integrated Clamping Systems One of the most significant advantages of custom-built welding tables is the ability to integrate specialized clamping systems. These systems can hold workpieces securely in place, allowing for more straightforward manipulations and increased precision. Adjustable clamps can accommodate various shapes and sizes, further enhancing a welder's efficiency.

custom built welding tables

4. Modularity and Expandability Many custom welding tables are designed with modularity in mind. This means that as the welder’s needs evolve, the table can be expanded or modified with additional attachments, such as shelves or tool organizers, allowing for a more versatile work environment.

5. Welding Accessories Custom tables can also be equipped with various accessories such as ground clamps, tool racks, and lighting solutions. These additions not only maintain a clean and organized workspace but also improve overall safety by keeping tools readily accessible.

Benefits of Using Custom Built Welding Tables

Custom built welding tables bring several advantages to both commercial and home workshops. First, the precise design ensures optimal ergonomics, reducing fatigue and enhancing comfort during prolonged use. With the right table, welders can work at an ideal height, preventing strain on their backs and arms.

Second, these tables enhance productivity. By having a workstation that is specifically tailored to their needs, welders can complete projects faster and with better accuracy. The efficiency gained from having the correct layout and tools at hand cannot be overstated.

Finally, custom welding tables can contribute to improved safety. A well-organized workspace minimizes the risk of accidents, ensuring that tools and materials are stored securely. Additionally, the heat-resistant surface helps prevent accidental fires, an essential consideration for any welding environment.

Conclusion

In conclusion, custom built welding tables are a foundational element of any serious welding operation. Their ability to cater to individual needs through tailored design features provides welders with a significant advantage in achieving quality results efficiently and safely. As the demand for customized solutions continues to grow, investing in a well-designed welding table will undoubtedly pay off, making the welding process more enjoyable and productive. Whether you're fabricating intricate pieces or performing heavy-duty welds, having the right table can make all the difference in your welding success.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS