Rhag . 30, 2024 19:24 Back to list

Understanding the Functionality and Benefits of Disco Check Valves in Fluid Systems

Understanding Disco Check Valves Functionality, Applications, and Benefits

In the world of fluid dynamics, the importance of check valves cannot be overstated. Among the various types of check valves, the disco check valve stands out due to its unique design and functionality. This article delves into what disco check valves are, how they work, their applications, and the benefits they provide.

What is a Disco Check Valve?

A disco check valve, often referred to as a double disc check valve, is a type of non-return valve that uses two discs to control the flow of fluid within a pipeline. Unlike traditional swing check valves, which have a single disc hinged at a pivot point, the disco check valve operates with a dual-disc mechanism. This configuration allows for a more efficient and effective sealing process, preventing backflow and ensuring smooth operation in various fluid systems.

How Do Disco Check Valves Work?

The operational mechanism of a disco check valve is relatively straightforward. When fluid flows through the valve in the intended direction, the pressure pushes the disc open, allowing the fluid to pass. In the event of a reverse flow, the discs are forced to close tightly against the valve seat, creating a seal that prevents backflow. This action minimizes the risk of contamination, ensures system efficiency, and protects downstream equipment from potential damage caused by backflow events.

Applications of Disco Check Valves

Disco check valves are versatile components found in a variety of industries and applications. Some common uses include

1. Water Supply Systems They are frequently employed in municipal water supply lines to prevent backflow that could contaminate drinking water.

2. Wastewater Treatment In wastewater systems, these valves help maintain the integrity of the treatment process by preventing undesired flow reversals.

3. Oil and Gas In the oil and gas industry, disco check valves are critical for preventing backflow in pipelines, ensuring the safe and efficient transport of hydrocarbons.

disco check valve

5. HVAC Systems In heating, ventilation, and air conditioning systems, disco check valves help regulate flow and maintain system stability.

Benefits of Using Disco Check Valves

The selection of disco check valves offers several advantages over other types of check valves

- Efficient Flow Control The dual-disc design allows for smoother operation, reducing turbulence and pressure drops in the system.

- Compact Design Compared to traditional swing check valves, disco check valves often require less space, making them ideal for installations with limited real estate.

- Enhanced Durability Their construction typically features robust materials that withstand corrosion and wear, extending the lifespan of the valve.

- Reliable Performance Disco check valves boast a high degree of reliability, ensuring that fluid flow remains unidirectional and preventing system failures.

- Easy Maintenance With fewer moving parts and a simple design, these valves are generally easier to maintain, leading to lower operational costs over time.

Conclusion

In summary, disco check valves play a vital role in various industries by ensuring unidirectional fluid flow and protecting systems from backflow-related issues. Their unique two-disc design provides numerous benefits, including efficient flow control, compactness, durability, and ease of maintenance. As the demand for reliable fluid control solutions continues to grow, the disco check valve stands out as a valuable component in modern engineering and industrial applications.

Whether you are involved in water supply, wastewater management, oil and gas transport, or any other fluid system, understanding the functionality and advantages of disco check valves can lead to better system design and improved operational efficiency. As industries continue to evolve and innovate, the importance of effective fluid control mechanisms, such as the disco check valve, will be ever more significant.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

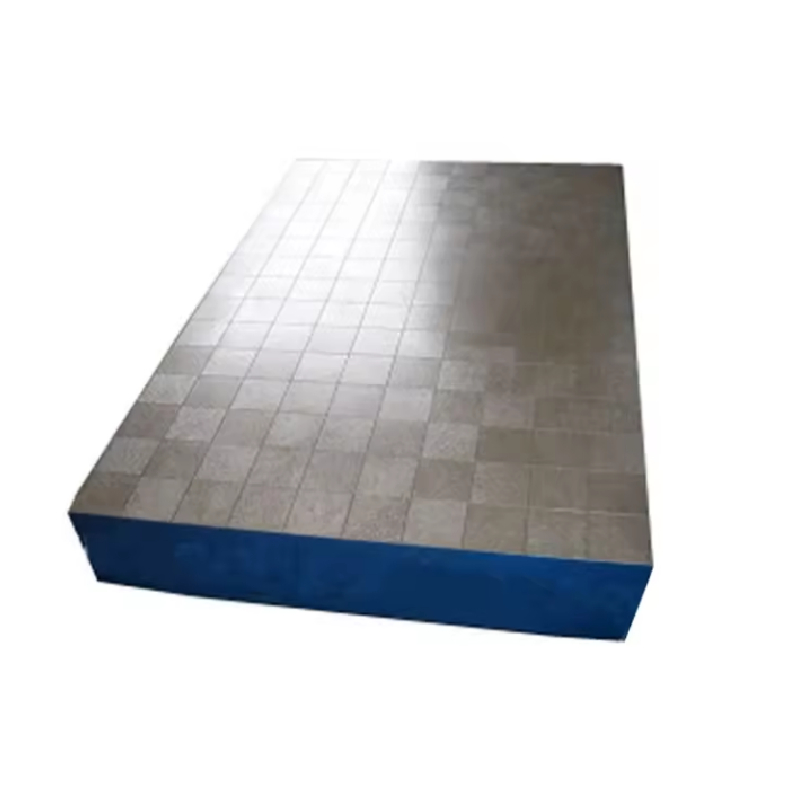

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS