Hyd . 12, 2024 03:50 Back to list

100mm Gate Valve Specifications and Applications for Industrial Use

Understanding the 100mm Gate Valve A Comprehensive Overview

Gate valves are one of the most fundamental components used in various piping systems across industries, providing the ability to start or stop the flow of liquids or gases. Among the variety of gate valves available in the market, the 100mm gate valve stands out due to its size, versatility, and efficiency. In this article, we will explore the various aspects of the 100mm gate valve, including its construction, applications, advantages, and maintenance.

Construction and Design

A 100mm gate valve features a unique design that consists mainly of a valve body, a gate (or wedge), a bonnet, and a handwheel for operation. The 100mm designation refers to the diameter of the valve's inlet and outlet, which is equivalent to approximately 4 inches. This size makes it suitable for moderate to heavy-duty applications, particularly in industrial settings.

Generally, these valves are constructed from diverse materials, such as stainless steel, cast iron, and ductile iron, depending on the service environment and application requirements. Stainless steel valves offer excellent corrosion resistance, making them ideal for corrosive fluids, while cast iron valves are often used in water supply applications due to their durability and cost-effectiveness.

Applications

The 100mm gate valve is widely used in numerous industries, including water treatment plants, chemical processing facilities, oil and gas industries, and power generation stations

. They are particularly advantageous in systems where a full bore flow is necessary, as the design allows for minimal pressure drop when fully open.100mm gate valve

Some common applications include 1. Water Supply Systems Used for regulating water flow in municipal water systems. 2. Sewage Treatment Helps to control the flow of sewage and wastewater for treatment processes. 3. Oil and Gas Pipelines Acts as a shut-off mechanism in pipeline systems to prevent unwanted flow. 4. Chemical Processing Controls the flow of chemicals in manufacturing processes.

Advantages of 100mm Gate Valves

1. Minimal Flow Resistance When fully opened, gate valves provide a straight-through flow path, ensuring minimal resistance and turbulence, which is highly desirable in many processes. 2. Durability With robust construction, 100mm gate valves are designed to withstand high pressures and temperature variations. They can effectively handle various fluids, including those that are viscous or contain solid particulates. 3. Low Operating Torque The design facilitates easier operation, requiring less torque to open or close the valve. This is particularly beneficial in larger systems where manual operation may be challenging. 4. Versatile Operation Gate valves can be operated manually via a handwheel or automatically using actuators, providing flexibility in operation according to the system design.

Maintenance and Care

Regular maintenance is essential to ensure the longevity and effectiveness of 100mm gate valves. Here are some maintenance tips - Inspection Regularly inspect the valve for leaks, corrosion, or wear and tear, especially in critical applications. - Lubrication Keep the stem and threads of the handwheel lubricated to facilitate smooth operation. - Testing Conduct periodic tests to ensure that the valve opens and closes properly without obstruction. - Cleaning Remove any debris or buildup around the valve to prevent it from affecting its operation.

Conclusion

The 100mm gate valve serves as a critical component across various industries, providing reliable flow control with robust performance. Its design and material choices ensure that it can withstand challenging conditions while offering the operator ease of use. Understanding its applications, advantages, and appropriate maintenance will enable industries to optimize their operations and ensure safety in fluid management systems. As technologies evolve, innovations in valve design and materials will continue to enhance the performance and efficiency of gate valves, further solidifying their position as a staple in industrial piping systems.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

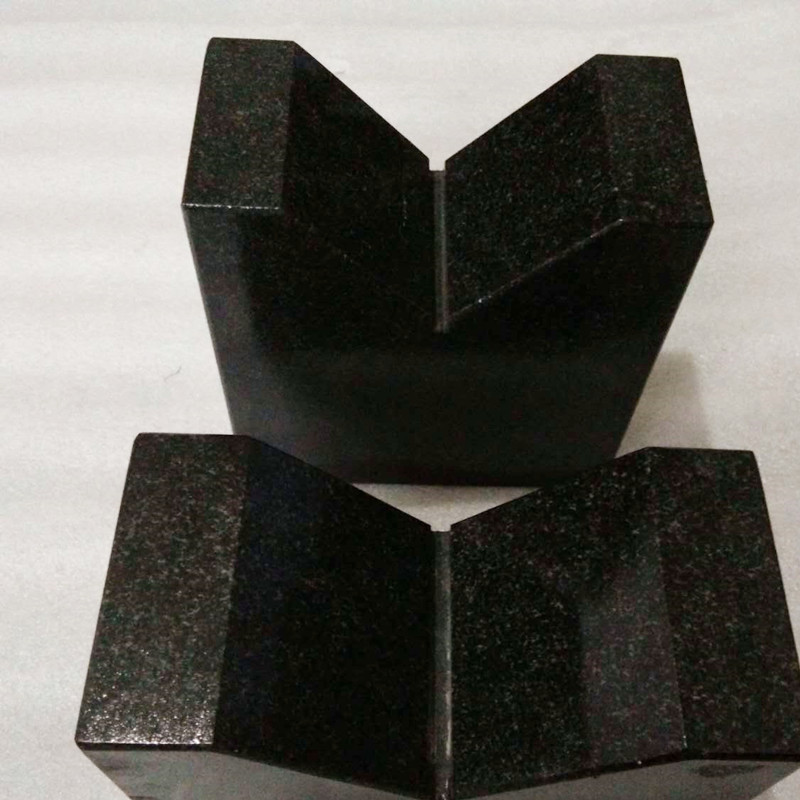

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS