Dec . 04, 2024 11:45 Back to list

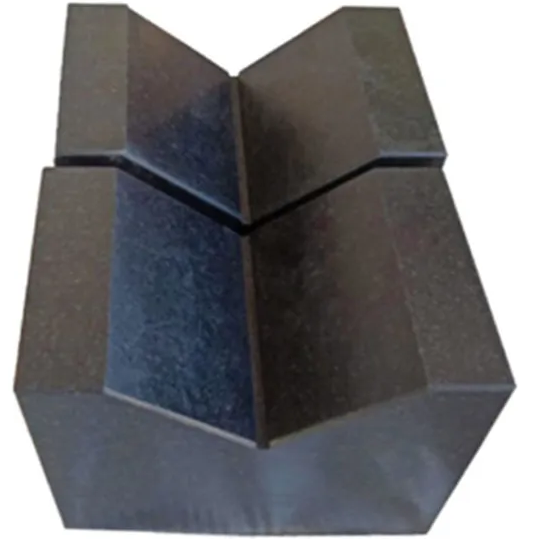

v guide rail

Understanding the Importance of V-Guide Rails in Modern Engineering

In engineering and manufacturing, precision and reliability are paramount. Among the various components that ensure the efficiency of machinery, V-guide rails stand out as crucial elements that play a significant role in a variety of applications, from manufacturing systems to transportation industries. This article explores the significance, characteristics, and advantages of using V-guide rails.

What Are V-Guide Rails?

V-guide rails are linear motion components typically made from materials such as steel, aluminum, or polymer. They are designed with a V shaped groove that allows for smooth and consistent movement of sliding components, ensuring that they travel in a straight line. These rails are commonly paired with corresponding wheel assemblies that fit snugly into the V-shaped grooves, allowing for minimal friction and wear over time.

Applications of V-Guide Rails

V-guide rails are widely used in numerous industries, including automation, robotics, and conveyor systems. In automation, for example, V-guide rails facilitate the smooth operation of robots that need to perform tasks with high precision. In conveyor systems, they guide the movement of goods, enhancing overall productivity by ensuring that items travel efficiently from one point to another.

Manufacturers also use V-guide rails in machinery that requires linear motion, such as CNC machines and laser cutters. These machines need to maintain strict tolerances while moving along predetermined paths, and V-guide rails enable such accuracy. Moreover, the durability of V-guide rails makes them ideal for heavy-duty applications where robustness and stability are critical.

Benefits of V-Guide Rails

v guide rail

1. Precision and Accuracy One of the primary advantages of using V-guide rails is their ability to provide precise movement. The V-groove design helps maintain alignment and reduces the chances of misalignment, ensuring that machinery operates smoothly and effectively.

2. Reduced Friction The design of V-guide rails significantly reduces friction between moving parts. Lower friction not only prolongs the lifespan of both the rails and the associated components but also results in energy savings as less force is required to initiate movement.

3. Durability V-guide rails are built to withstand heavy loads and harsh operating conditions. Their robust construction means they can endure impact, wear, and environmental factors, making them a reliable choice for demanding applications.

4. Ease of Installation and Maintenance Installing V-guide rails is often straightforward, and maintenance typically involves regular inspections rather than extensive interventions. This simplicity can lead to reduced downtime and lower overall operational costs.

5. Versatility V-guide rails can be adapted for various applications and can be combined with different types of motion systems. Their versatility allows engineers to implement them in numerous configurations tailored to specific project needs.

Conclusion

In summary, V-guide rails are essential components in the realm of engineering and manufacturing, ensuring that machines operate with precision, efficiency, and reliability. Their ability to facilitate smooth linear motion makes them indispensable in a myriad of applications ranging from automotive assembly lines to advanced robotic systems. As industries continue to evolve and seek ever-more efficient ways to optimize processes, the role of V-guide rails is likely to expand, reinforcing their significance in contemporary manufacturing and engineering solutions. By understanding and leveraging the benefits of V-guide rails, organizations can enhance productivity and maintain a competitive edge in the market.

-

Surface Plate Maintenance Best Practices for LongevityNewsJun.27,2025

-

Historical Evolution of Iron Surface Plates in Industrial MetrologyNewsJun.27,2025

-

Cast Iron Y Strainer Safety StandardsNewsJun.27,2025

-

Blockchain Verification for Gauge Tool Certification IntegrityNewsJun.27,2025

-

Advantages of Triple Offset Butterfly Valve Types in High-Pressure SystemsNewsJun.27,2025

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

Related PRODUCTS