Nov . 16, 2024 19:36 Back to list

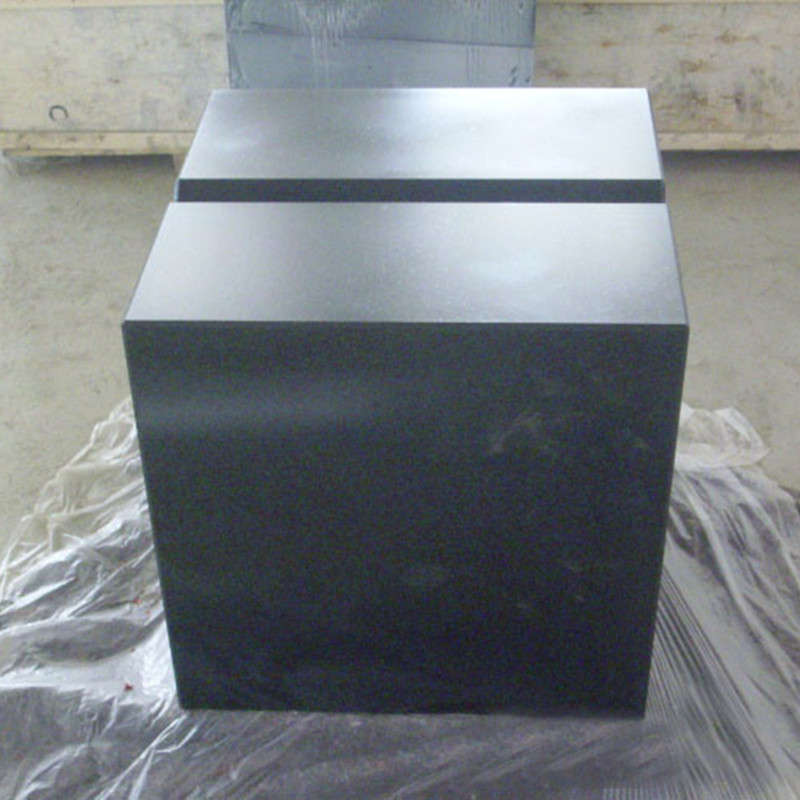

magnetic v block working

Understanding the Working Principle of Magnetic V Blocks

When it comes to precision machining, ensuring the stability and accuracy of workpieces during operations is paramount. One tool that has gained significant popularity in this regard is the magnetic V block. This specialized clamping device is designed to securely hold cylindrical objects, ensuring they remain stationary while being drilled, milled, or ground. In this article, we will explore the functionality of magnetic V blocks, their applications, advantages, and limitations.

What is a Magnetic V Block?

A magnetic V block is a precision tool that features a V-shaped groove along its length, allowing it to easily accommodate round or cylindrical workpieces. The block is equipped with a powerful electromagnet or permanent magnet, which provides a strong magnetic force to hold ferromagnetic materials securely in place. This capability is particularly beneficial in machining processes where any movement can lead to inaccuracies or defects.

The Working Principle

The working principle of a magnetic V block hinges on the basic concepts of magnetism. When the magnet is activated, either through electrical power in the case of electromagnets or as a result of the inherent magnetic properties of the material, the magnetic field generated attracts ferromagnetic workpieces. The V groove provides two primary contact points, ensuring that the cylindrical object is held at both ends and stabilized during machining.

1. Activation of the Magnet In electromagnet types, when electric current flows through the coil wrapped around the core of the block, it generates a magnetic field strong enough to hold the workpiece firmly. Permanent magnets, contrarily, retain their magnetism regardless of external power.

2. Placement of the Workpiece The workpiece is placed within the V groove. The design allows diverse sizes of cylindrical materials to fit securely, optimizing the block's capability to hold various diameters with precision.

3. Securing the Workpiece Once the workpiece is positioned, the magnet is activated (if using an electromagnet), pulling the workpiece tightly against the flat surfaces of the block. This prevents any shifting, even under the mechanical forces exerted during machining operations.

Applications

magnetic v block working

Magnetic V blocks are versatile and used in a variety of industries, including

- Metalworking Often employed during drilling, milling, or grinding operations, they ensure accuracy by preventing the workpiece from rotating or shifting. - Inspection Used in coordinate measuring machines (CMM) for holding cylindrical parts in place during inspection processes. - Welding They can also assist in securing cylindrical components where welds are needed, maintaining the desired alignment until the weld solidifies. - Assembly In assembly lines where cylindrical components must be accurately positioned together before final fastening.

Advantages

The magnetic V block offers several advantages

- Stability Provides a robust grip that minimizes vibration and movement, ensuring precision. - Ease of Use Can be quickly activated and deactivated, which reduces setup time in machining operations. - Flexibility Accommodates a range of cylindrical sizes due to its V-shape design. - Durability Often made of tough materials, these blocks can withstand the rigors of machining environments.

Limitations

Despite their numerous benefits, magnetic V blocks also have limitations

- Material Restriction They are primarily effective for ferromagnetic materials and cannot hold non-magnetic workpieces. - Magnetic Interference Proximity to other magnetic devices or unshielded electronics can interfere with the block's magnetic field, potentially leading to unreliable performance. - Limited Size Range While they are versatile, the size of the workpiece must conform to the dimensions of the block’s V groove.

Conclusion

Magnetic V blocks serve as an essential tool in precision machining and assembly processes, offering both stability and versatility for various cylindrical workpieces. By understanding their working principles, applications, advantages, and limitations, machinists can effectively incorporate these tools into their workflow, leading to enhanced precision and efficiency in their operations. Whether in a professional machine shop or a DIY workshop, the magnetic V block remains a staple for those seeking reliable workpiece stability.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS