Jul . 27, 2024 16:28 Back to list

Exploring the Benefits and Applications of Ductile Iron Check Valves in Industrial Systems

The Role and Significance of Ductile Iron Check Valves

Ductile iron check valves play a crucial role in various industries, particularly in water and wastewater treatment, oil and gas, and chemical processing. Known for their durability and resilience, these valves are vital components that help regulate the flow and prevent backflow in piping systems. This article explores the features, benefits, and applications of ductile iron check valves, highlighting their importance in modern engineering.

Understanding Ductile Iron

Ductile iron, also known as nodular cast iron, is a type of cast iron that has superior mechanical properties compared to traditional cast iron. This material is created by adding small amounts of magnesium to the molten iron, which transforms the graphite structure into spherical shapes. As a result, ductile iron boasts increased strength, ductility, and impact resistance. These characteristics make it an ideal choice for manufacturing check valves that must withstand harsh operational conditions.

Function of Check Valves

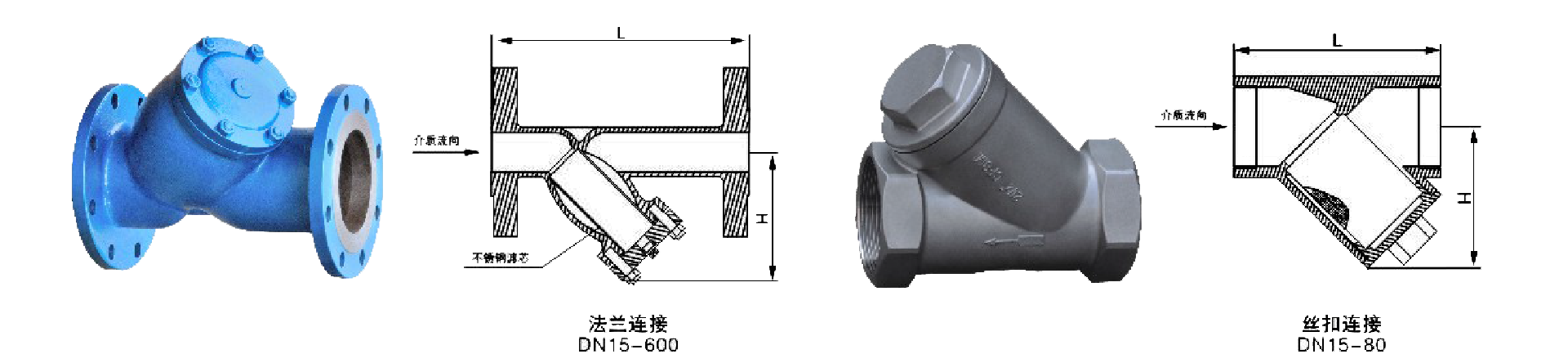

Check valves are designed to allow fluid flow in one direction while preventing backflow. This characteristic is crucial in maintaining system integrity and preventing damage caused by reverse flow. Ductile iron check valves are particularly effective due to their robust construction, which ensures a tight seal and reliable performance. The valve's mechanism typically consists of a disc that opens to allow flow and closes against the seat when the flow decreases or reverses.

Advantages of Ductile Iron Check Valves

1. Durability Ductile iron check valves offer excellent resistance to wear and tear, making them suitable for high-pressure and high-temperature applications. Their robust nature reduces the likelihood of failure, ensuring long-term service life.

ductile iron check valve

2. Corrosion Resistance Many ductile iron check valves are coated with protective layers, such as epoxy, to enhance their resistance to corrosion. This feature is particularly important in water treatment applications, where valves are exposed to various chemicals and environmental factors.

3. Versatile Applications Ductile iron check valves can be used in a wide range of applications, including water distribution systems, sewage systems, and industrial processes. Their adaptability makes them a preferred choice for engineers and project managers.

4. Improved Flow Characteristics The design of ductile iron check valves allows for minimal pressure loss and turbulence during operation. This feature is crucial for maintaining efficiency in fluid transport systems.

5. Ease of Maintenance Ductile iron check valves are typically designed for easy access, making maintenance and inspection straightforward. This benefit reduces downtime and operational costs associated with valve servicing.

Applications in Industry

Ductile iron check valves are extensively used in various sectors. In the water and wastewater industry, they help prevent contamination of clean water supplies by blocking backflow from wastewater systems. In oil and gas applications, these valves ensure that harmful fluids do not flow back into the storage tanks or pipelines, mitigating environmental risks. In chemical processing, they allow for safe handling of corrosive substances, enhancing operational safety.

Conclusion

Ductile iron check valves are indispensable components in modern piping systems, offering a combination of strength, durability, and efficiency. Their unique properties make them ideal for a variety of challenging environments, ensuring reliable operation and preventing backflow. As industries continue to seek solutions that enhance safety and efficiency, ductile iron check valves will undoubtedly remain at the forefront of engineering materials, contributing to sustainable and effective system designs. Investing in high-quality ductile iron check valves will yield long-term benefits, making them a worthy consideration for any industrial application.

-

Small Hole Gauge Use in Aerospace Component TestingNewsJun.13,2025

-

Flanged Strainer Use in Marine EnvironmentsNewsJun.13,2025

-

Affordable Welding Tables for Educational WorkshopsNewsJun.13,2025

-

Y Type Strainer Future InnovationsNewsJun.12,2025

-

Marine Applications Gate Valve TypesNewsJun.12,2025

-

Granite Tools for Sale OnlineNewsJun.12,2025

Related PRODUCTS