Nov . 06, 2024 22:13 Back to list

Comparing Cast Iron and Block Materials for Optimal Performance and Durability in Engineering

Cast Iron vs. Block Understanding the Differences and Applications

When it comes to engine construction and automotive engineering, materials matter significantly in terms of performance, durability, and cost-effectiveness. Two common materials used in creating engine blocks and other critical components are cast iron and aluminum alloy blocks. Each material has its unique set of properties, benefits, and drawbacks, making them suitable for specific applications. This article will explore the differences between cast iron and aluminum blocks, their advantages and disadvantages, and their role in the world of automotive and machinery.

What is Cast Iron?

Cast iron is an iron-carbon alloy containing a high percentage of carbon, which imparts significant strength and hardness. There are several types of cast iron, including gray cast iron, ductile iron, and white cast iron, each having unique properties. Gray cast iron, widely used in engine blocks, is known for its excellent castability, wear resistance, and good machinability. It also has natural lubricating properties due to the graphite flakes dispersed within the matrix, which can be beneficial for engine longevity.

Understanding Engine Blocks

Engine blocks serve as the core structure of an internal combustion engine where crucial components like pistons, cylinders, crankshafts, and camshafts are housed. The choice of material for the engine block can significantly impact the engine's performance, weight, and efficiency. Traditionally, cast iron has been the go-to material for many years due to its strength and heat resistance, but advancements in technology have led to increased usage of aluminum alloys.

Advantages of Cast Iron

1. Durability and Strength Cast iron is incredibly strong and can withstand high stress and loads, which is essential for high-performance engines. 2. Thermal Conductivity Cast iron has good thermal conductivity, which helps in maintaining optimal engine temperatures and prevents overheating.

3. Cost-Effective Generally, cast iron is less expensive than its aluminum counterparts, making it an attractive option for manufacturers.

Disadvantages of Cast Iron

1. Weight Cast iron is significantly heavier than aluminum, which can negatively impact the overall weight of the vehicle and its performance, especially in terms of acceleration and fuel efficiency.

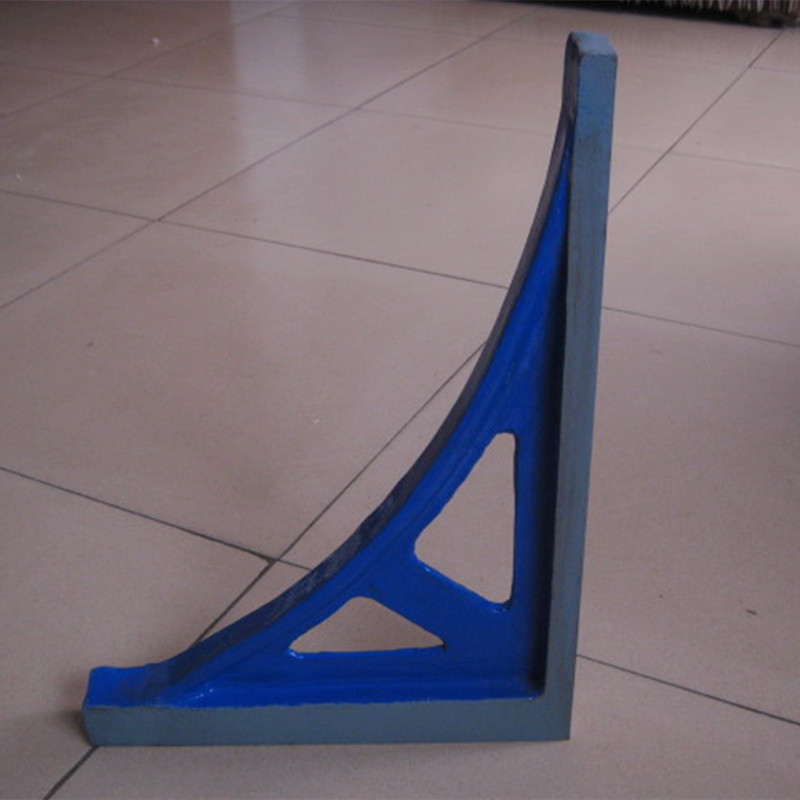

cast iron v block

2. Corrosion Risk While cast iron is durable, it is susceptible to rust if exposed to moisture and corrosive elements without adequate protective coatings.

Advantages of Aluminum Blocks

1. Lightweight One of the most significant advantages of aluminum is its low weight, which contributes to better fuel efficiency and handling in vehicles.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer, making it more resistant to corrosion compared to cast iron.

3. Easier to Machine Aluminum blocks are generally easier to machine and modify, allowing for more design flexibility and faster production times.

Disadvantages of Aluminum Blocks

1. Strength While aluminum alloys can be strong, they do not match the tensile strength of cast iron, making them less suitable for high-stress applications.

2. Heat Dissipation Aluminum can lose heat faster than cast iron, which might become an issue in high-performance engines that require stable thermal management.

Conclusion

In the ongoing debate of cast iron versus aluminum blocks, the right choice hinges on the specific application and performance requirements. Cast iron offers unparalleled strength and durability, making it ideal for heavy-duty applications and high-performance engines. In contrast, aluminum provides a lightweight, corrosion-resistant alternative that is perfect for modern vehicles requiring greater fuel efficiency and agile handling.

Ultimately, both materials play crucial roles in the automotive world, and manufacturers will continue to innovate and develop new materials to enhance engine performance. Understanding the differences between cast iron and aluminum blocks will help consumers make informed decisions and appreciate the engineering behind modern automobiles.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS