Nov . 09, 2024 14:55 Back to list

Comprehensive Guide to Pin Gauge Set Variability and Applications in Precision Measurement

Understanding Pin Gauge Sets and Their Ranges

Pin gauge sets are essential tools in precision engineering, manufacturing, and quality control processes. Designed to measure holes, the diameter of a workpiece, or to set tolerances in machinery, these gauges play a crucial role in ensuring that parts fit together correctly and perform optimally. This article will explore the significance of pin gauge sets, their ranges, and their applications in various industries.

What is a Pin Gauge Set?

A pin gauge set consists of a series of precision ground pins, each with a specific diameter. These pins are typically made from high-quality materials like tool steel or carbide to provide durability and maintain accuracy. The pins are manufactured to stringent tolerances, ensuring that each gauge is reliable for measuring dimensions. The set usually covers a range of sizes, allowing users to verify hole diameters and other related measurements effectively.

The Importance of Measurement Ranges

The range of a pin gauge set refers to the spectrum of pin diameters it includes. A typical set may range from a small size, such as 0.5 mm, to larger sizes exceeding 10 mm or even more, depending on the set's design. The range is important for several reasons

1. Versatility in Applications A wide range means that a single set of pin gauges can be utilized across various applications and industries, from automotive and aerospace to electronics and medical device manufacturing. This flexibility reduces the need for multiple tools, streamlining the measuring process.

2. Precision Verification With a comprehensive range, engineers and quality control technicians can precisely verify the dimensions of both internal and external features. This is critical for ensuring that components fit together correctly, which is vital for the performance and longevity of machinery and assemblies.

3. Enhanced Quality Control Industries that require strict adherence to dimensions often implement pin gauge sets as part of their quality control processes. Having pin gauges that cover a broad range allows for thorough inspections at various stages of production, ensuring that any discrepancies can be identified and corrected promptly.

pin gauge set range

4. Ease of Use Pin gauges are straightforward to use. By inserting the appropriate pin into a hole, users can instantly determine whether the hole is within tolerance. If the pin fits perfectly, the dimension is correct; if it doesn’t, further adjustments may be required.

Application Areas of Pin Gauge Sets

Pin gauge sets find applications in various fields

- Manufacturing In manufacturing environments, pin gauges are commonly used to check the size of drilled holes, ensuring they meet design specifications. They are invaluable for machining processes where precision is critical.

- Tool and Die Making Toolmakers use pin gauge sets to assess the accuracy of molds and dies, which must meet exacting standards for mass production purposes.

- Maintenance and Repairs Technicians use pin gauges during maintenance to check whether parts have worn to the point where they no longer fit correctly, allowing for timely replacements.

- Aerospace and Automotive Industries In these sectors, the safety and performance of components are paramount. Pin gauge sets help ensure that all parts meet rigorous standards before being assembled into larger systems.

Conclusion

In conclusion, pin gauge sets serve as an invaluable resource in precision measurement across multiple industries. Their range of sizes allows for versatility and thorough inspection, helping to maintain quality and performance standards essential in today's manufacturing environment. Whether in a factory, a workshop, or a quality control laboratory, pin gauges play a critical role in ensuring that products meet their design specifications and function as intended. As technology continues to advance, the importance of precision tools like pin gauge sets will only increase, reaffirming their place in modern engineering and manufacturing.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

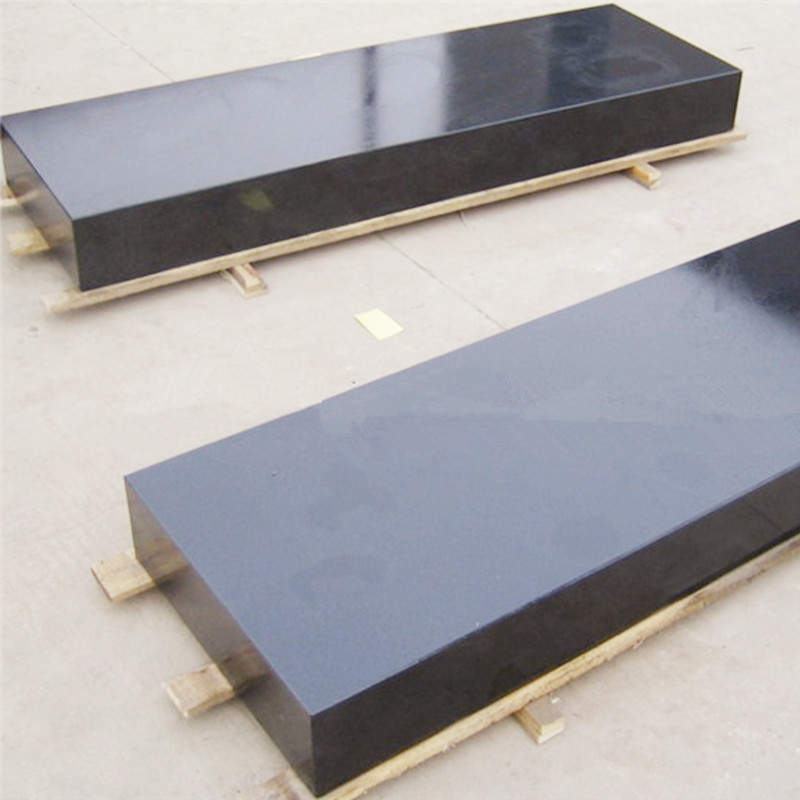

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS