Set . 12, 2024 11:32 Back to list

Precision Machinist Gauge Pin Set | High-Quality Measuring Tools

Understanding the Machinist Gauge Pin Set Essential Tools for Precision Engineering

In the world of precision engineering, the machinist gauge pin set stands as a vital tool for professionals who strive for accuracy and reliability in their work. These small, cylindrical pins are designed to provide exact measurements, making them indispensable in a variety of applications, from machining to quality control in manufacturing processes.

A machinist gauge pin set typically includes a range of pins with precise diameters, allowing machinists to check hole sizes, alignments, and tolerances with ease

. The pins are often made from high-quality materials to ensure durability and longevity, as well as to maintain accuracy over time. Common materials include steel or carbide, which provide robustness and resistance to wear, an essential quality given the demanding environment in which these tools are often used.One of the primary uses of a gauge pin set is to measure the internal dimensions of holes. The pins can be inserted into drilled or machined holes to verify their diameter and ensure that they meet specified tolerances. This function is critical in industries such as automotive, aerospace, and manufacturing, where even minute discrepancies can lead to significant problems down the line. By using a range of pins, machinists can quickly and accurately determine whether a given hole is within acceptable limits.

machinist gauge pin set

Moreover, gauge pins serve another essential purpose they are used for alignment and setup. In situations where precise positioning is critical, such as in the setup of a CNC machine or the calibration of complex machinery, gauge pins can assist in achieving the correct alignment. By utilizing gauge pins, machinists can establish reference points and ensure that components are installed accurately, leading to better overall performance and reduced manufacturing errors.

Another important aspect of machinist gauge pins is their role in quality assurance. The consistency and accuracy of manufactured components can be verified using these pins, helping to maintain high standards in production. By regularly checking tools and machines with gauge pins, companies can identify wear or drift in measurements early, allowing for timely adjustments before issues escalate.

Furthermore, many machinist gauge pin sets feature a corresponding gauge or tolerance chart. This reference allows machinists to understand the specific tolerance levels for particular applications, further enhancing the precision of their work. With this information at their fingertips, machinists can make informed decisions about the appropriate pin to use in various scenarios, streamlining the measurement process.

In summary, the machinist gauge pin set is an invaluable tool in the field of precision engineering. Its ability to measure, align, and verify makes it essential for professionals dedicated to maintaining high-quality standards in their work. As industries continue to demand greater accuracy and reliability, the role of machinist gauge pins will undoubtedly remain a cornerstone of precision machining and quality control. With the right set of gauge pins, machinists can ensure that their work meets the rigorous demands of modern manufacturing, ultimately contributing to better products and enhanced operational efficiency.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

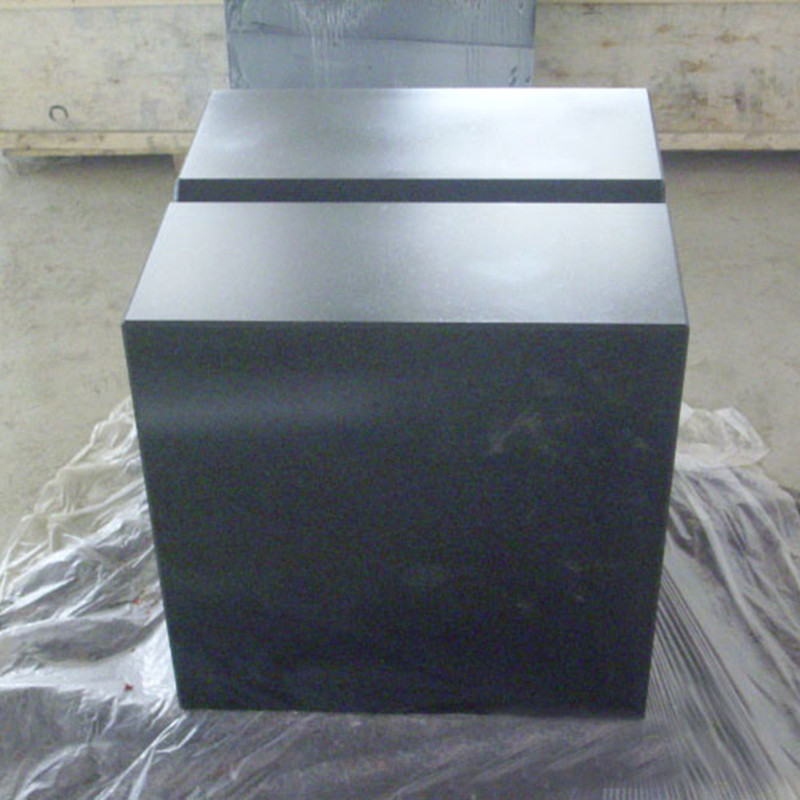

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS