Set . 26, 2024 05:36 Back to list

fabrication table

Understanding Fabrication Tables A Comprehensive Guide

In the world of manufacturing and engineering, the term fabrication table is a cornerstone concept that is integral to various processes. A fabrication table is a flat, sturdy surface used as a workstation for assembling parts, conducting fabrication tasks, and performing various engineering functions. This article seeks to enlighten you about the significance, types, and best practices associated with fabrication tables.

The Importance of Fabrication Tables

Fabrication tables serve several critical purposes in various industries including metalworking, woodworking, and electronics. They provide a dedicated space for fabricators to conduct their work efficiently and safely. Here are some key reasons why fabrication tables are essential

1. Precision and Accuracy Fabrication tables often come with built-in measuring tools and grids to help workers make precise cuts and alignments. This accuracy is crucial in ensuring that components fit together seamlessly during the assembly process.

2. Material Support A robust fabrication table can support heavy materials, allowing for easier handling and manipulation. This is particularly important for industries dealing with large metal sheets or bulky woodworking materials.

3. Safety A designated workspace for fabrication helps to minimize clutter and potential hazards. By keeping tools and materials organized, workers can focus on their tasks without distractions or safety risks.

4. Multipurpose Use Many fabrication tables are designed to accommodate a variety of tasks, from welding and cutting to assembly and finishing. This versatility allows businesses to switch between operations without the need for multiple workstations.

Types of Fabrication Tables

Fabrication tables come in various designs tailored to specific industries and tasks. Understanding the different types can help businesses choose the right one based on their unique requirements.

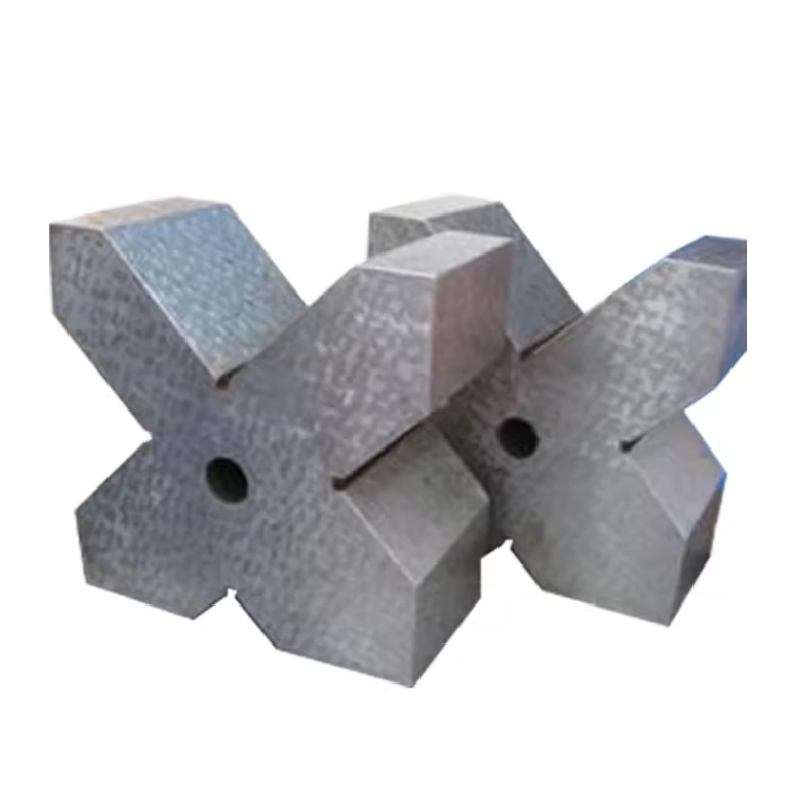

1. Welding Tables Equipped with a flat, metallic surface conducive for welding, these tables often have built-in clamps and fixtures to hold materials securely in place during the welding process. Their sturdy design can withstand the high heat generated in welding.

2. Assembly Tables These tables are designed for assembling components or products. They often combine a flat surface with compartments for tools and materials, facilitating an organized workflow. Some assembly tables even include power strips for electric tools.

fabrication table

3. Mobile Fabrication Tables These versatile tables are equipped with wheels, making them easy to move around the workshop. This mobility allows fabricators to optimize their workspace based on current tasks, thereby improving efficiency.

4. Custom Fabrication Tables Some businesses require specific features that standard tables do not offer. Custom fabrication tables can be designed to meet particular specifications, including adjustable heights, additional storage, and specialized fixtures.

Best Practices for Using Fabrication Tables

To maximize the utility of fabrication tables, users should adhere to certain best practices

1. Maintain a Clean Workspace Regularly tidy the area, removing scraps and unnecessary tools. A clean workspace promotes safety and enhances productivity.

2. Use Appropriate Tools Always select the correct tools for the job at hand. This not only ensures accuracy but also prolongs the lifespan of the table itself.

3. Regularly Inspect and Maintain Periodically check the structural integrity of the table. Inspect for dents, rust, or loose bolts that could compromise its functionality.

4. Organize Tools and Materials Utilize drawer systems and compartments to keep tools and materials organized. This practice not only saves time but also reduces the risk of accidents.

5. Follow Safety Protocols Equip the workspace with necessary safety gear and adhere to safety guidelines. Employing best safety practices reduces the risk of injuries substantially.

Conclusion

Fabrication tables are vital tools in the manufacturing and engineering sectors, providing a stable, precise, and safe environment for various tasks. Understanding their importance, the types available, and best practices for use can greatly enhance a worker's efficiency and safety. Whether you are a seasoned fabricator or new to the industry, investing in a quality fabrication table tailored to your specific needs will undoubtedly pay off in terms of productivity and quality. Embrace these essentials and elevate your fabrication work to new heights!

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS