Nov . 09, 2024 19:05 Back to list

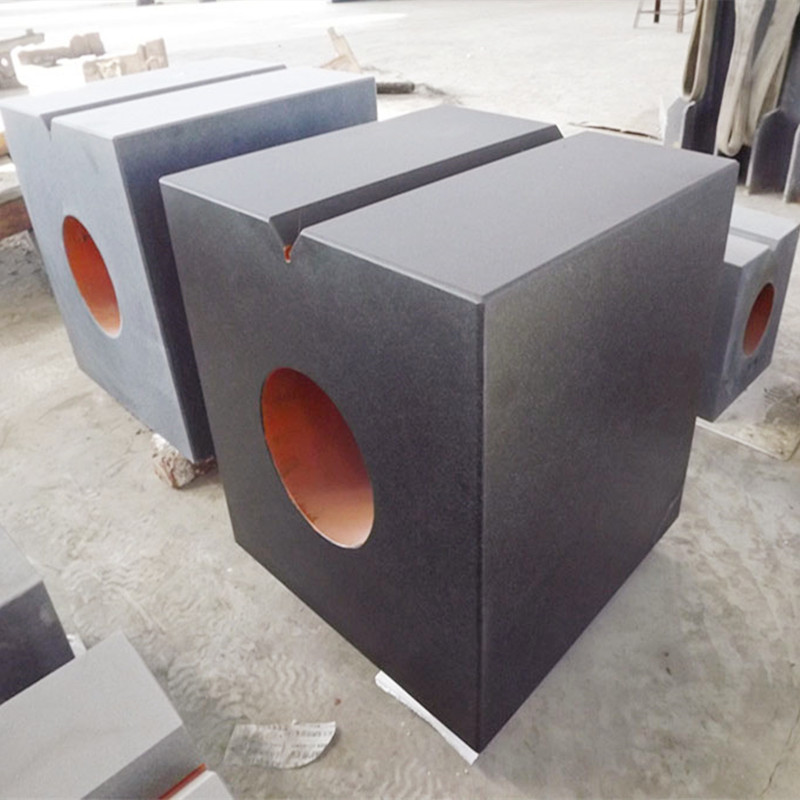

Quality Manufacturing Solutions for Butterfly Valves in a Modern Factory Setting

The Importance of Butterfly Valve Factories in Modern Industry

Butterfly valves are an essential component in various industrial applications, providing efficient and reliable flow control for fluids and gases. The manufacturing of these valves takes place in specialized butterfly valve factories, which play a crucial role in ensuring that industries have access to high-quality products that meet specific requirements. This article delves into the significance of butterfly valve factories, their operational processes, and the impact they have on various sectors.

Understanding Butterfly Valves

A butterfly valve is a quarter-turn rotational motion valve that uses a flat circular disc (the butterfly) to regulate the flow of a medium. The disc pivots on a shaft to open or close the valve, offering minimal pressure drop and making it suitable for applications in water supply, chemical processing, oil and gas, and HVAC systems. Due to their lightweight design and quick operation, butterfly valves are favored over other types of valves in many situations.

The Manufacturing Process

Butterfly valve factories employ advanced manufacturing techniques to produce valves that meet stringent industry standards. The process typically involves several key steps

1. Raw Material Selection Quality starts with the selection of raw materials. Factories often use materials such as stainless steel, cast iron, and plastic, depending on the application requirements. Each material has its own benefits, such as corrosion resistance, strength, and ease of fabrication.

2. Precision Machining Using CNC (computer numerical control) machines, manufacturers achieve precise dimensions and tolerances for valve components. This step is critical because even slight deviations can lead to leakage or malfunction.

3. Assembly Once the components are machined, they undergo assembly. This may include the installation of seals and gaskets, which are vital for preventing leaks. Skilled technicians ensure that each valve operates smoothly and correctly.

4. Testing Quality assurance is a significant aspect of butterfly valve manufacturing. Factories conduct various tests, including pressure tests and flow tests, to ensure that the valves function correctly under different conditions. Certifications may also be acquired to comply with industry regulations.

5. Finishing Finally, the valves are treated with protective coatings, such as epoxy or other finishes, to enhance durability and resistance to corrosive environments. Each valve is then labeled and prepared for shipping.

butterfly valve factory

The Role of Butterfly Valve Factories in Industry

Butterfly valve factories are a cornerstone in various industries, providing vital components that ensure safety and efficiency. Here are a few ways they impact modern industry

- Energy Sector In oil and gas applications, butterfly valves are essential for regulating the flow of fluids through pipelines. Factories that produce high-quality valves contribute to safer and more efficient energy distribution.

- Water Treatment Water treatment facilities rely on butterfly valves to control the flow of water, both in treatment processes and in distribution. Factories producing these valves ensure that clean water is delivered safely and efficiently.

- Chemical Processing The chemical industry often requires valves that can withstand high pressures and resist corrosion. Specialized butterfly valve factories that focus on these requirements play a critical role in the overall safety and efficiency of chemical processing plants.

- HVAC Systems Butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems to control airflow. Factories that produce these valves contribute to the effectiveness of climate control in residential and commercial buildings.

The Future of Butterfly Valve Manufacturing

As industries evolve, so do the technologies used in manufacturing. The introduction of automation and robotics in butterfly valve factories is set to enhance production efficiency while reducing human error. Additionally, the growing focus on sustainability will likely drive manufacturers to develop eco-friendly valves that consume less energy and are recyclable.

Moreover, the integration of smart technology into butterfly valves, such as sensors and actuators, will enable remote monitoring and advanced control systems, optimizing performance and maintenance protocols.

Conclusion

Butterfly valve factories are more than just production facilities; they are vital contributors to the functioning of modern industry. By producing high-quality, reliable valves, these factories ensure that industries can operate efficiently, safely, and sustainably. As technology continues to advance, the role of butterfly valve manufacturers will only become more critical in responding to the demands of a rapidly changing industrial landscape.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS