Dis . 03, 2024 16:24 Back to list

5 Inch Butterfly Valve Specifications and Applications for Efficient Fluid Control

Understanding the 5% 20 Inch Butterfly Valve Design, Functionality, and Applications

Butterfly valves are widely recognized as effective devices for regulating fluid flow in various industrial applications. Among these, the 5% 20-inch butterfly valve stands out for its size, design, and functional efficiency. This article delves into the essential characteristics, functionalities, and applications of this type of butterfly valve, offering a comprehensive overview.

Overview of Butterfly Valves

Butterfly valves consist of a circular disc or vane that rotates about a central axis within the valve body. The mechanism is analogous to a butterfly's wings, where the disc opens and closes to control fluid passage. Structurally, butterfly valves are simple, which allows for quick opening and closing, making them an efficient choice for flow regulation.

Design Characteristics of the 5% 20 Inch Butterfly Valve

The designation 20-inch refers to the nominal diameter of the valve, indicating that it can manage substantial volumes of fluids. The 5% in the description often refers to the valve's optimal opening or its flow coefficient, which is related to its flow characteristics. For various industrial uses, a 5% opening offers precise control for processes requiring low flow rates.

Material Composition Butterfly valves can be manufactured from various materials, including stainless steel, cast iron, PVC, and more, depending on the application's nature. For instance, stainless steel butterfly valves are highly durable and resistant to corrosion, making them suitable for environments where the fluid may be aggressive.

Design Variants The 5% 20-inch butterfly valve typically comes in two main designs wafer-style and lug-style. Wafer-style valves are sandwiched between two flanges, offering a compact design and ease of installation. Conversely, lug-style valves have threaded holes allowing for their removal or replacement without needing to drain the entire system.

Functionality

The primary function of a butterfly valve is to regulate fluid flow, and its mechanism allows for various control functions. The design allows for quick transitions from fully open to fully closed positions, minimizing flow resistance.

Flow Control One of the main advantages of the 5% 20-inch butterfly valve is its superior flow control. By adjusting the position of the disc, operators can achieve specific flow rates, ranging from fully closed to a precise 5% opening. This attribute is particularly beneficial in processes requiring fine-tuning of flow variables.

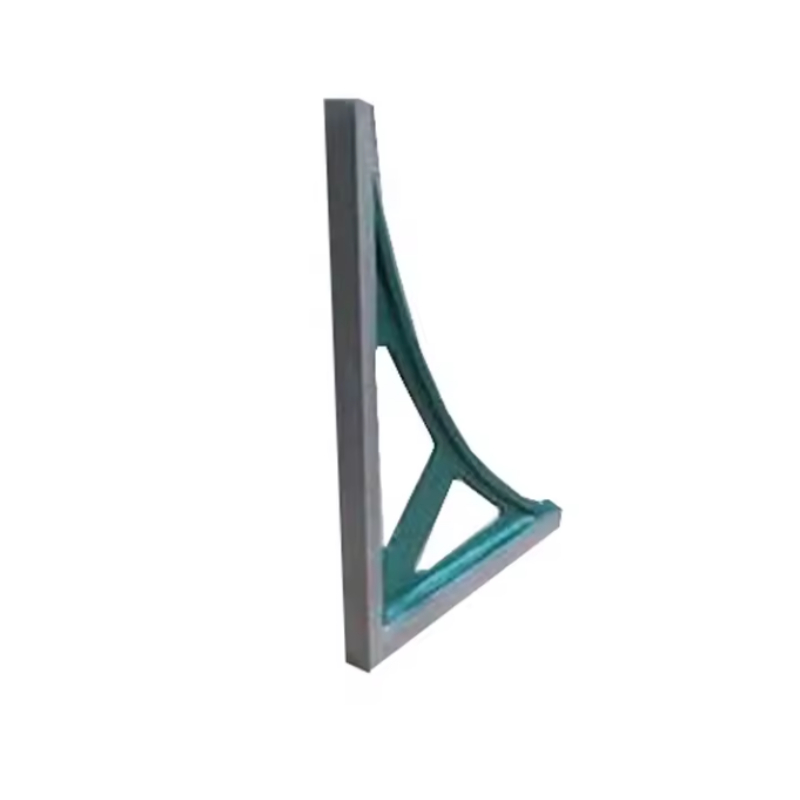

5 inch butterfly valve

Pressure and Temperature Resistance Butterfly valves are designed to operate in various pressure and temperature conditions. The materials used in construction play a significant role in determining how well a valve can withstand mechanical stress, ensuring longevity and reliability.

Applications

The versatility of the 5% 20-inch butterfly valve makes it suitable for a range of applications across multiple industries

1. Water Treatment In water treatment facilities, these valves are crucial for controlling the flow of water through various filtration and purification systems.

2. Chemical Processing The resistance to corrosion and pressure makes this butterfly valve ideal for handling chemicals in industrial processes.

3. Oil and Gas Used in the transportation and processing of oil and gas, the valve's efficient flow control is essential for maintaining safe and effective operations.

4. HVAC Systems In heating, ventilation, and air conditioning systems, butterfly valves regulate airflow and temperature, contributing to efficient energy use.

5. Power Plants These valves are often found in power generation facilities, managing water, steam, and other crucial fluids.

Conclusion

The 5% 20-inch butterfly valve epitomizes efficiency in fluid flow management across diverse industrial applications. With its simple yet effective design, excellent flow control capabilities, and robustness against harsh conditions, this butterfly valve serves as a reliable solution for engineers and operators aiming to optimize their processes. As industries continue to advance, the importance of such components will only grow, highlighting their role in ensuring seamless operations while maintaining safety and efficiency.

Understanding and selecting the right butterfly valve can significantly impact operational efficiency and longevity, making it crucial for professionals in the field to stay informed about the latest technologies and best practices in valve selection and application.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS