maig . 28, 2025 17:23 Tornar a la llista

Top Features to Look for in a Welding Table Workbench

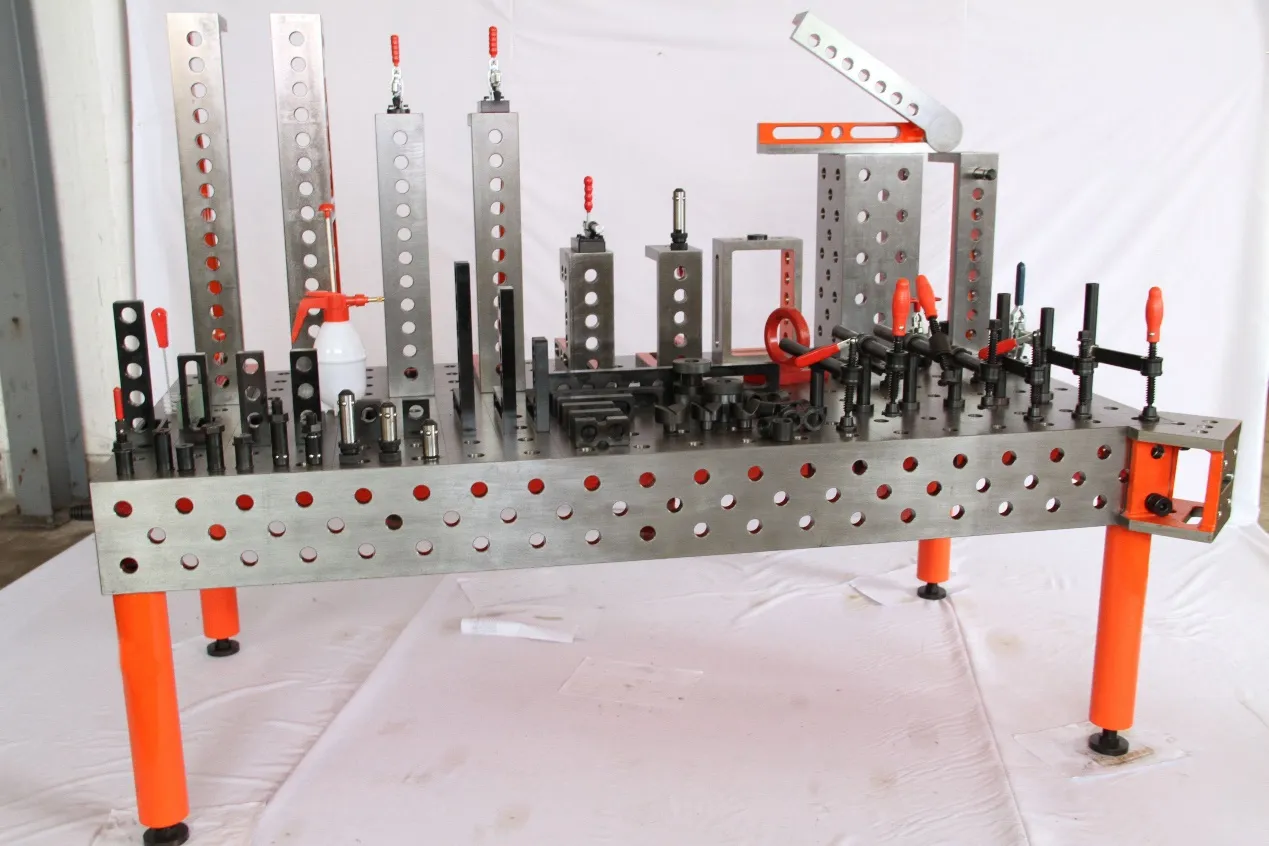

A high-quality welding table is the foundation of any metalworking shop, providing stability, precision, and efficiency for all your fabrication needs. Whether you're searching for a steel welding table for sale understanding the key features will help you make the best investment. This guide explores essential characteristics of a top-performing welding table workbench and why an easy welding table design can significantly improve your workflow.

Material and Construction Quality Of Welding Table Workbench

The first consideration when choosing a welding table workbench is the material. Steel welding tables offer excellent durability and heat resistance, making them ideal for heavy-duty applications. Cast iron welding tables provide superior vibration dampening and stability, though they may be heavier and more expensive.Look for thick, flat tabletop surfaces (at least 1/2 inch thick) to prevent warping under high heat. Reinforced legs and cross-bracing ensure stability, while rust-resistant coatings extend the table's lifespan. A well-built welded steel workbench should withstand years of grinding, hammering, and welding without deformation.

Work Surface And Clamping Options Of Welding Table Workbench

A functional welding table workbench should provide multiple clamping and fixture possibilities. Many professional-grade tables feature a grid of precision-drilled holes (such as 5/8" or 16mm) for modular tooling, allowing for quick setup of jigs and fixtures.Some easy welding table designs incorporate slotted channels or T-tracks for adjustable clamping, while magnetic fixtures can further enhance flexibility. The best tables allow for 360-degree access, enabling welders to position piecework at optimal angles without obstruction.

Mobility And Adaptability Features Of Welding Table Workbench

While stability is paramount, mobility can be equally important in many workshop environments. Look for welding table workbench models with heavy-duty locking casters, allowing easy repositioning when needed. Some steel welding tables feature height-adjustable legs or tilting tops for ergonomic benefits.Additionally, consider the workspace layout and the specific welding tasks you'll be performing. Select a welding table workbench that offers ample surface area to accommodate your projects and tools, ensuring efficient workflow and minimal clutter. Furthermore, ensure the welding table is constructed from durable materials capable of withstanding the high temperatures and sparks generated during welding processes.For shops with limited space, fold able or modular easy welding table designs provide smart solutions. However, ensure any mobility features don't compromise the table's rigidity during precise welding operations.

Heat And Spatter Resistance Of Welding Table Workbench

A professional welded steel workbench must endure extreme temperatures and welding spatter without deteriorating. Thick steel or cast iron tops naturally resist heat distortion, while specialized coatings or treatments can further protect the surface.Certain welding tables come equipped with built-in cooling systems or heat-resistant barriers to enhance durability. Additionally, the legs and frame should be sturdy enough to withstand the stress and heat generated during welding processes, ensuring long-term stability and safety.Some high-end cast iron welding tables feature replaceable top plates or sacrificial surfaces that can be resurfaced over time. Copper or brass inserts in critical areas help prevent weld sticking in common work zones. Proper spatter resistance means less cleanup time and longer table longevity.

Welding Table Workbench FAQs

What's better - a steel or cast iron welding table workbench?

Steel welding tables offer great durability at lower cost, while cast iron welding tables provide better vibration absorption and thermal stability. The choice depends on your budget and specific welding applications.

How thick should a welding table workbench top be?

For most professional applications, look for at least 1/2" thickness in a steel welding table or 1" for cast iron welding tables. Thicker materials resist warping and provide better heat dissipation.

Are modular fixture systems of welding table workbench worth the investment?

Absolutely. A welding table workbench with precision hole patterns dramatically improves setup speed and accuracy, paying for itself in saved labor time on complex projects.

What maintenance does a welding table workbench require?

Regular cleaning to remove spatter, occasional resurfacing of the work area, and checking/replacing any damaged fixture components will keep your welded steel workbench in top condition.

Where can I find high-quality welding table workbench at wholesale prices?

Our company specializes in premium steel welding table for sale options at competitive wholesale rates.For wholesalers we provide top-tier welded steel workbench solutions at competitive prices. Elevate your workshop's efficiency - browse our catalog today and discover why professionals trust our welding tables for their most demanding projects.Our welding tables are engineered for durability and precision, ensuring that your welding projects are completed with accuracy and reliability. With adjustable features and robust construction, our welding tables cater to a wide range of welding needs, from intricate detail work to heavy-duty fabrication. Don't settle for subpar equipment - choose our welding tables and experience the difference in quality and performance.

-

Why the Right Angle Ruler Reigns in MetalworkingNotíciesJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNotíciesJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNotíciesJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNotíciesJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNotíciesJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNotíciesJul.21,2025

Productes relacionats