oct. . 07, 2024 15:36 Back to list

hydraulic check valve types

Understanding Hydraulic Check Valve Types

Hydraulic check valves are crucial components in hydraulic systems, ensuring that fluid flows in one direction while preventing backflow. These essential devices maintain pressure and protect equipment from damage caused by reverse fluid movement. Various types of hydraulic check valves are available, each designed for specific applications and operating conditions. Understanding these types can assist engineers and designers in selecting the right valve for their systems.

1. Inline Check Valves

Inline check valves are the most common type, typically installed in the pipework of a hydraulic system. They allow fluid to flow freely in one direction and automatically close to prevent backflow when the fluid flow reverses. Inline check valves can be either spring-loaded or swing-type. Spring-loaded valves use a spring mechanism to keep the valve closed when fluid is not flowing, while swing-type valves use a hinged disc that swings open with forward flow and closes under back pressure.

Ball check valves have a spherical ball that acts as the sealing mechanism. When fluid flows in the designated direction, the ball lifts off its seat, allowing for smooth passage. If backflow occurs, the ball is forced against the seat, sealing off the reverse flow. This design provides a tight seal and is particularly effective in applications where leakage must be minimized. Ball check valves are often used in systems requiring tight sealing and minimal pressure loss.

3. Pilot-operated Check Valves

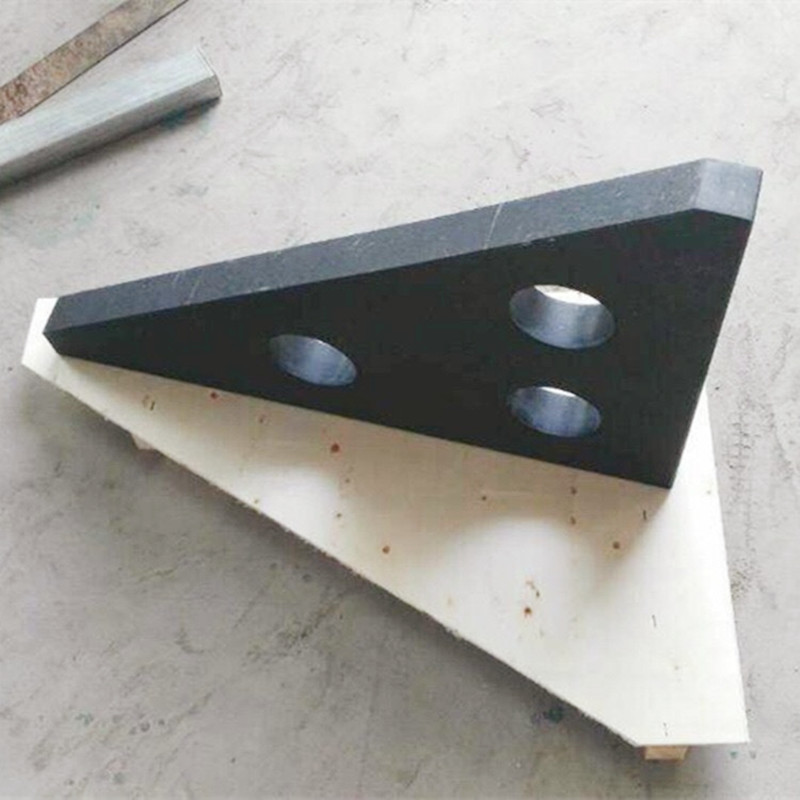

hydraulic check valve types

Pilot-operated check valves are sophisticated devices that use a pilot signal to control the valve's operation. In normal conditions, these valves prevent backflow; however, they can be opened under specific conditions, allowing for controlled flow reversal. This feature is beneficial in applications where precise flow management is essential, such as in hydraulic actuators or circuits requiring load-holding capabilities.

4. Dual-check Valves

Dual-check valves incorporate two check valves in one body, allowing for redundancy and improved performance. This design ensures that if one valve fails, the other can still function, significantly enhancing system reliability. These valves are particularly useful in applications where safety and reliability are paramount, such as in food processing or pharmaceuticals.

5. Disc Check Valves

Disc check valves feature a disc that pivots to control the flow direction. They are known for their quick response time and reduced pressure drop compared to other check valve types. Disc check valves are favored in high-velocity applications and are available in both spring-assisted and gravity-assist designs.

In conclusion, selecting the appropriate type of hydraulic check valve is vital for the efficiency and reliability of hydraulic systems. Understanding the unique features and applications of each valve type—from inline to pilot-operated—enables engineers to make informed decisions, ensuring optimal performance and longevity of the hydraulic systems they design. Proper selection not only enhances system functionality but also safeguards equipment, contributing to overall operational reliability.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS