des. . 11, 2024 10:01 Back to list

Similar Options for 3 and 4-Inch Globe Valves with Specifications

Understanding Globe Valves Essentials and Applications

Globe valves are a crucial component in various piping systems, known for their ability to control flow effectively. These valves, characterized by their spherical body shape, operate using a movable disc or ball that can obstruct or allow fluid passage. This article delves into what globe valves are, their features, types—focusing specifically on 3-inch and 4-inch models—and their applications in different industries.

What is a Globe Valve?

A globe valve is a type of valve used to regulate the flow of fluids. It consists of a valve body, a movable disk or plug, and a stationary seat. The design of the globe valve allows for precise throttling capabilities, making it a popular choice for applications where flow control is paramount. Unlike gate valves which are mainly used for fully open or fully closed operations, globe valves can be finely adjusted to any position in between, providing significant advantages in maintaining flow rates.

Design and Construction

The body of a globe valve generally features a spherical shape with an internal baffle that separates the inlet and outlet. This shape creates a longer flow path for the fluid, which ultimately increases pressure drop. While globe valves can handle a substantial amount of pressure, the increased pressure drop means they may not be suitable for every application, particularly where minimal pressure loss is essential.

The main components of a globe valve include

- Body Houses the internal components and is typically made from materials such as brass, stainless steel, or cast iron. - Disc/Plug The movable part that opens or closes the flow path. - Seat The fixed surface against which the disc seals to stop the flow. - Stem The rod that connects the disc to the actuator or handwheel to allow for operation. - Actuator The mechanism used to open or close the valve, which can be manual or automated.

The 3-Inch and 4-Inch Globe Valves

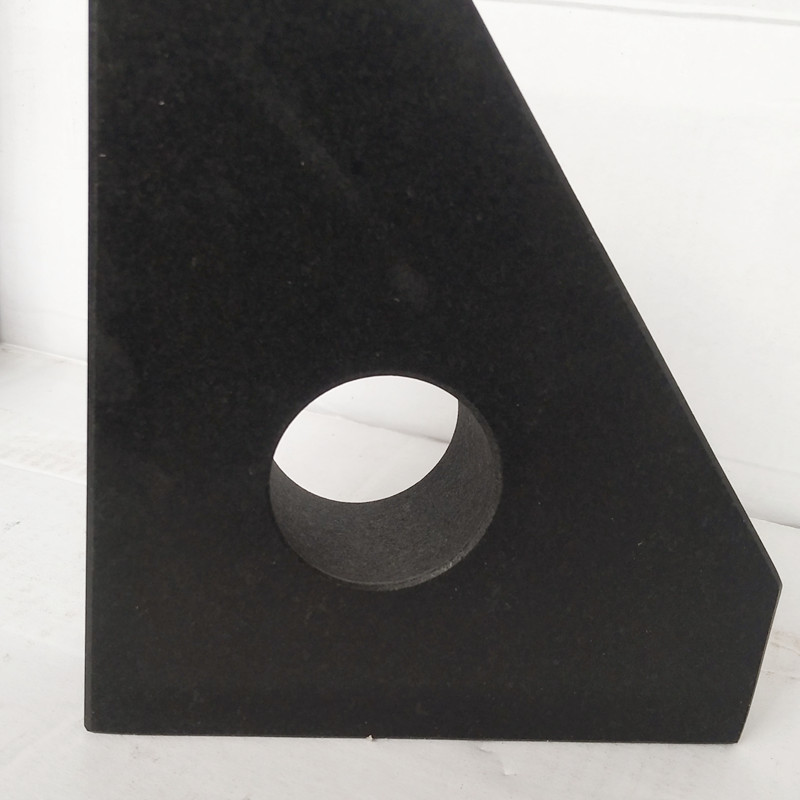

globe valve 3 4

Globe valves come in various sizes, and the 3-inch and 4-inch variants are common in industrial applications. The choice between these sizes typically depends on the desired flow rate and the design specifications of the piping system.

3-Inch Globe Valve - Typically used in applications where space is a constraint but adequate flow control is necessary. - Ideal for smaller industrial processes, HVAC systems, and irrigation setups. - Offers good throttling performance without taking too much space.

4-Inch Globe Valve - Suitable for larger systems that require higher flow rates. - Often seen in chemical processing plants, power stations, and large-scale irrigation. - Provides a robust design that can handle greater pressure and volume compared to smaller valves.

Both these sizes can be found in various materials and designs, offering flexibility based on the media being controlled—ranging from water to steam, gases, and even corrosive fluids.

Applications in Various Industries

Globe valves play a vital role across multiple sectors, including

- Oil and Gas Essential for controlling the flow of crude oil, natural gas, and refinery products. - Water Treatment Used in filtration and distribution systems to regulate the flow of treated water. - Power Generation Integral to cooling systems and steam control in power plants. - HVAC Controls heating and cooling media within complex building systems.

In conclusion, globe valves, particularly the 3-inch and 4-inch models, are pivotal in ensuring the efficient and reliable operation of system processes across various industries. Their ability to precisely control fluid flow and adapt to specific requirements makes them a preferred choice in many piping systems. Understanding their design and applications can help engineers and technicians make informed decisions when designing or maintaining such systems, ensuring optimal performance and safety.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS