nov . 11, 2024 12:34 Back to list

spline gage calibration

Spline Gage Calibration Ensuring Precision in Measurement

Calibration is a critical process in the field of measurement, ensuring that instruments provide accurate and reliable data. Among the various measurement tools, spline gages play a vital role in industries that require precise dimensions and geometrical accuracy. Spline gage calibration is essential for maintaining the integrity of manufacturing processes, ensuring quality control, and ultimately delivering products that meet or exceed performance standards.

Understanding Spline Gages

Spline gages are specialized tools used to measure the width and depth of spline grooves in various mechanical components such as gears, shafts, and couplings. A spline is a linear feature that engages with a corresponding feature to transmit torque or motion. Accurate measurement of splines is crucial as any discrepancies can lead to misalignments, performance issues, or outright mechanical failures. Spline gages typically come in various shapes and sizes, designed to fit specific spline profiles and configurations.

Importance of Calibration

Calibration is the process of comparing an instrument's output with a known standard. For spline gages, this involves checking their dimensions against reference values defined by industry standards. The primary goal is to ensure that measurements taken with the gage are accurate and consistent over time. Regular calibration is essential for several reasons

1. Quality Assurance In manufacturing, maintaining product quality is paramount. A calibrated spline gage ensures that every measurement taken is reliable, thus preventing defects and reducing the cost associated with rework or scrap.

2. Compliance Many industries are subject to stringent regulations that require accurate measurement of components. Calibration helps companies adhere to these regulations, avoiding potential fines or penalties.

3. Preventive Maintenance Over time, gages can wear out or be subject to environmental factors that affect their accuracy. Regular calibration helps identify any drift in measurements, enabling proactive maintenance before issues arise.

4. Improved Efficiency Accurate measurements reduce the time spent in troubleshooting and re-evaluating components. This leads to smoother production processes, enhancing overall productivity.

spline gage calibration

Calibration Process

The calibration of spline gages typically involves several key steps

1. Preparation Ensure that the calibration environment is clean and controlled. Factors like temperature, humidity, and vibration can affect the measurement process.

2. Selection of Standards Use certified reference standards that are traceable to national or international standards. These references serve as the baseline for checking the spline gage's accuracy.

3. Measurement Use the spline gage to take measurements on the reference standards. This process may involve multiple readings to assess consistency.

4. Comparison and Adjustment Compare the measurements taken with the standards. If discrepancies are found, the gage may need to be adjusted or repaired.

5. Documentation Record all calibration results, adjustments, and any maintenance performed. This documentation is crucial for quality assurance and regulatory compliance.

6. Recalibration Frequency Establish a regular recalibration schedule based on the gage's usage, the environment, and industry standards. Regular checks are vital to maintaining accuracy over time.

Conclusion

In a world where precision is paramount, the importance of calibrating spline gages cannot be overstated. This vital process ensures that measurements are not only accurate but also reliable, ultimately resulting in superior product quality and performance. As industries continue to evolve and demand higher standards, effective calibration practices will remain a cornerstone of successful manufacturing operations. Investing in proper calibration techniques not only enhances productivity but also bolsters a company’s reputation in the competitive landscape of modern manufacturing.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

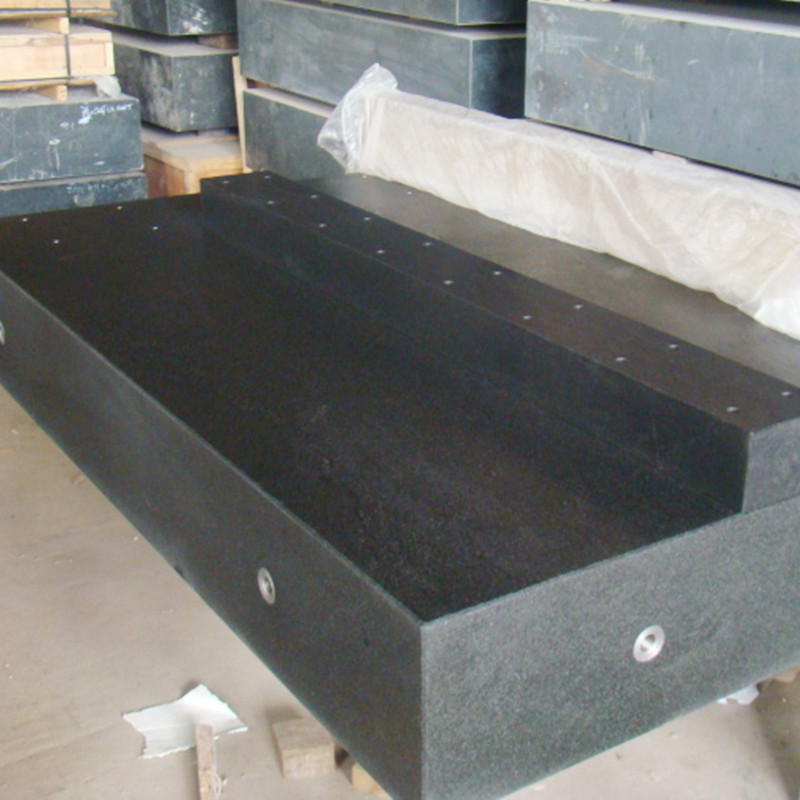

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS