sep . 13, 2024 15:07 Povratak na listu

Exploring V Blocks for Sale

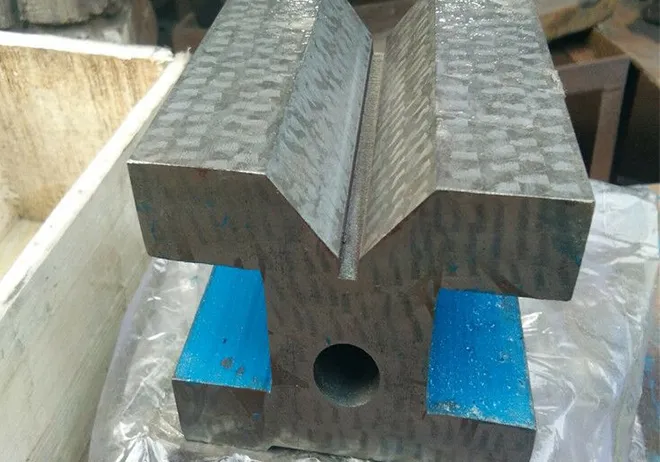

V blocks are critical tools used in metalworking and machining, primarily designed to support cylindrical components such as shafts, tubes, and sleeve-shaped parts. These blocks are often used for securing, inspecting, or marking workpieces to ensure precision during manufacturing processes. V blocks for sale are available in a range of sizes and materials, with cast iron and metal being the most popular for industrial applications due to their durability and high accuracy.

V blocks are supplied in pairs, ensuring that cylindrical components can be securely held in place while keeping the axial lead parallel to the working surface. These tools are widely applied in various industrial tasks such as lineation (marking lines for cutting or machining), fixing positions, and clamping in the production of precision shaft-like parts.

Common Uses:

- Supporting cylinder-shaped components for machining.

- Ensuring the axial lead remains parallel to the platform surface.

- Marking, clamping, and positioning during production processes.

The Benefits of a Frame V Block in Precision Machining

Frame V blocks are specifically designed to provide secure support for cylindrical workpieces in both machining and inspection tasks. These blocks are known for their sturdy frame structure, which makes them ideal for tasks that require a stable and reliable base. The V-shaped groove in the block holds the component tightly in place, allowing for high precision during drilling, milling, and grinding operations.

The frame V block is commonly used in industries such as automotive manufacturing, aerospace, and general machining, where accurate positioning and stability are crucial for the production of high-quality components. These blocks are typically made from materials such as hardened steel or cast iron to ensure long-lasting performance and resistance to wear.

Key Features:

- Sturdy frame structure ensures stability during operations.

- Ideal for holding cylindrical components in place.

- Provides high precision in machining tasks like drilling and milling.

Versatility of Vee Blocks for Industrial Tasks

Vee blocks (also spelled as V blocks) are widely used in machining and metalworking for securely holding cylindrical or shaft-like parts in place during various operations. The V-shaped groove, which gives the block its name, allows it to grip round objects securely, making it ideal for positioning, clamping, and inspection tasks.

Vee blocks are incredibly versatile, as they can be used in a variety of applications, including:

- Marking and lineation: These blocks allow operators to mark accurate lines on cylindrical parts before machining.

- Inspection: Used to check whether cylindrical components are straight and true by rotating the part within the groove.

- Clamping: Vee blockscan be used with clamps to securely hold the part in place during machining operations like milling, drilling, or grinding.

Available in both magnetic and non-magnetic versions, vee blocks are essential for tasks requiring precision and stability, especially in environments where metal parts need to be positioned and machined accurately.

Applications:

- Securely holding round or cylindrical workpieces during machining.

- Ensuring accurate positioning and inspection of parts.

- Suitable for drilling, milling, and marking operations.

High-Performance Cast Iron V Blocks for Heavy-Duty Tasks

Cast iron V blocks are known for their robust construction, making them ideal for supporting heavy cylindrical components during machining and inspection processes. Cast iron offers excellent durability and stability, which are critical when working with large or heavy parts, ensuring that the component remains securely in place without shifting.

These cast iron V blocks are widely used for tasks such as:

- Precision machining: Supporting shaft-like parts during grinding, milling, or drilling.

- Inspection: Checking cylindrical components for accuracy and alignment.

- Clamping and positioning: Ensuring the workpiece is properly aligned and held in place for various manufacturing processes.

Cast iron V blocks are often supplied in pairs to allow for consistent support on both ends of the workpiece, providing stability and ensuring that the axial lead remains parallel to the working surface. The heavy-duty nature of these blocks makes them a preferred choice for machine shops and industries where precision is paramount.

Advantages:

- Strong and durable cast iron construction for heavy-duty use.

- Ideal for supporting large cylindrical components.

- Provides stable support for precision machining and inspection.

Precision and Stability with Metal V Blocks

Metal V blocks are precision tools used to hold cylindrical or shaft-like workpieces securely in place during machining operations. Available in various materials, including steel and cast iron, metal V blocks are designed to provide high accuracy, stability, and durability in industrial applications.

These blocks are often used for:

- Grinding and milling: Holding components steady to ensure precision during metal removal processes.

- Inspection: Checking for straightness or alignment by rotating the cylindrical part in the V-groove.

- Marking and lineation: Accurate marking of cylindrical parts before they are machined.

Metal V blocks are essential in industries that require high levels of precision and durability, such as automotive manufacturing, aerospace, and heavy equipment production. The blocks are designed to withstand the wear and tear of regular use while maintaining accuracy, making them a valuable addition to any machine shop.

Features:

- Available in steel, cast iron, or hardened metal for long-lasting performance.

- Provides secure positioning for precision machining tasks.

- Suitable for holding and inspecting cylindrical components.

V blocks, including frame V blocks, vee blocks, and cast iron V blocks, are essential tools in metalworking and precision machining. These blocks provide stable and secure support for cylindrical components during machining, inspection, and marking processes. Whether you're working with small or large components, metal V blocks ensure high precision and durability, making them indispensable in industries like automotive manufacturing, aerospace, and general machining.

Explore our selection of V blocks for your precision machining needs and ensure the stability and accuracy of your cylindrical components in every project!

-

Thread Plug Gauge Requires Careful HandlingVijestiJul.29,2025

-

Surface plate calibrationVijestiJul.29,2025

-

Ring Gauge Ensures Machining AccuracyVijestiJul.29,2025

-

Pad Iron Reinforces Anchor PointsVijestiJul.29,2025

-

Ground anchor stabilizes embankmentsVijestiJul.29,2025

-

Granite Box Maintains Precision FlatnessVijestiJul.29,2025

Srodni proizvodi