ডিসে. . 07, 2024 07:53 Back to list

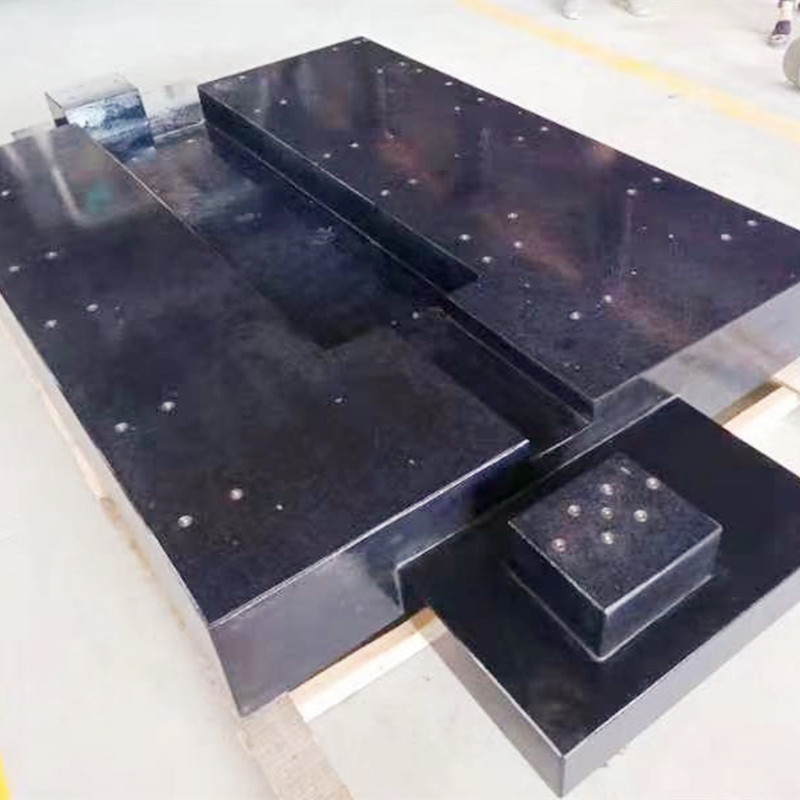

pin gauge

Understanding Pin Gauges Precision Tools for Quality Control

Pin gauges play a crucial role in ensuring the quality and precision of various manufactured products. These simple yet effective measurement tools are widely used in industries such as manufacturing, engineering, and assembly, where exact specifications are paramount. In this article, we will explore what pin gauges are, their applications, advantages, and how they contribute to maintaining high standards in quality control.

What are Pin Gauges?

Pin gauges are small, cylindrical measuring devices that come in various diameters. They are typically made from high-quality materials, such as hardened steel, to withstand wear and tear. The primary purpose of a pin gauge is to check the diameter of holes, slots, or any other dimensional features in a workpiece.

Available in sets, pin gauges are often used to determine whether a specific opening meets the required tolerance levels. They can be either go or no-go gauges, where the go pin must fit into the hole, indicating that the dimension is acceptable, while the no-go pin is too large to fit, signaling that the dimension exceeds specified limits.

Applications of Pin Gauges

Pin gauges are versatile tools employed across various applications

1. Quality Control In manufacturing processes, pin gauges are integral to quality assurance. They allow technicians to verify that parts meet engineering specifications, helping to catch defects early in the production cycle.

2. Machining and Assembly During machining operations, pin gauges help to ensure that holes and slots are correctly sized before assembly. This is vital in industries like automotive and aerospace, where even minor discrepancies can lead to significant issues.

3. Tool Making Pin gauges are often used in tool making to check the dimensions of tools and molds. This ensures that the tools produced will work effectively in their intended applications.

4. Testing and Calibration Pin gauges can be used for testing and calibrating measuring instruments themselves. By comparing the gauge pins to the measurements of these instruments, users can verify their accuracy.

Advantages of Using Pin Gauges

pin gauge

The use of pin gauges offers several advantages

- High Accuracy Due to their precise manufacturing process, pin gauges provide high levels of accuracy. This makes them indispensable in applications where precision is critical.

- Simplicity and Ease of Use Pin gauges are straightforward to use. Operators simply insert the pin into the hole or slot to check for fit, making it an efficient process.

- Cost-Effective Compared to complex measurement systems, pin gauges are relatively inexpensive. They provide an excellent solution for organizations seeking to maintain quality without significant financial investment.

- Durability Made from hardened materials, pin gauges have a long service life, retaining their accuracy over time, which adds to their overall cost-effectiveness.

Maintaining Pin Gauges

To ensure the longevity and accuracy of pin gauges, regular maintenance is essential. Here are some tips

1. Cleaning After each use, it is crucial to clean pin gauges to remove any dirt, oil, or debris. This helps to prevent corrosion and maintain accuracy.

2. Storage Proper storage is vital. Pin gauges should be kept in protective cases or racks to prevent damage and misalignment.

3. Calibration Periodic calibration against a master gauge is necessary to maintain accuracy over time. This helps ensure that the gauges remain within their specified tolerances.

Conclusion

Pin gauges are an essential tool in the realm of manufacturing and quality control. Their simplicity, accuracy, and cost-effectiveness make them invaluable for checking the dimensional integrity of components. By providing a reliable means of measurement, they help industries uphold quality standards and deliver products that meet specifications. As technology continues to evolve, the fundamental role of pin gauges in maintaining precision and quality will remain indispensable, ensuring that industries continue to function smoothly and efficiently.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS