ডিসে. . 11, 2024 12:05 Back to list

magnetic v block size

The Importance of Magnetic V Blocks Understanding Size, Functionality, and Applications

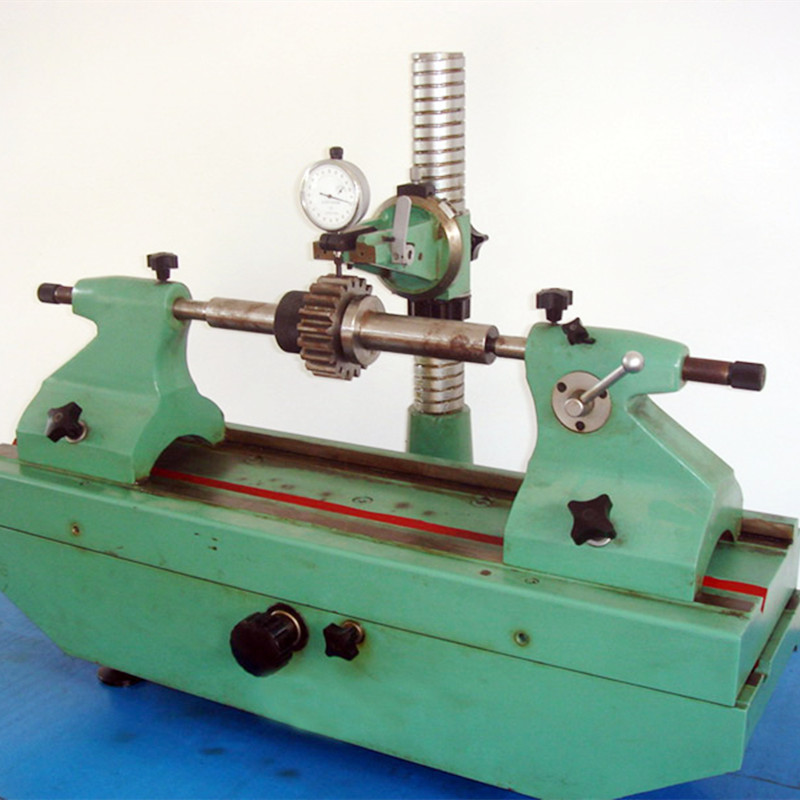

Magnetic V blocks are essential tools in the machining and metalworking industries, primarily used for securing workpieces during inspection, grinding, and machining processes. The size of these magnetic V blocks plays a critical role in their effectiveness and versatility. This article will explore the significance of magnetic V block sizes, their functionality, and varied applications across different industries.

What are Magnetic V Blocks?

Magnetic V blocks are precision-engineered tools made from durable materials with strong magnetic capabilities. They feature a V-shaped groove, allowing for the secure positioning of cylindrical objects, such as rods and shafts. The unique design ensures that the workpiece remains stable during various procedures, enhancing accuracy and safety.

Importance of Size

The size of a magnetic V block can significantly impact its usability and effectiveness. Here are several factors to consider

1. Workpiece Dimensions The primary consideration when selecting a magnetic V block is the size of the workpiece. Smaller blocks are suitable for holding smaller items, while larger blocks provide enhanced support for bigger workpieces. An appropriate size not only increases holding power but also optimizes stability.

2. Workspace Constraints The physical workspace available can also dictate the size of the V block chosen. In a limited workspace, a compact magnetic V block will be essential to ensure that operations can be conducted without obstruction. Conversely, larger V blocks may be necessary in more expansive setups where different types of workpieces are handled.

3. Weight Capacity Different sizes of magnetic V blocks come with varying weight capacities. It's crucial to select a block that can support the specific workpiece to be machined or inspected. Using an inadequate size may lead to accidents or damage to both the workpiece and the machinery.

Functionality

A properly sized magnetic V block enhances productivity through its unique features

magnetic v block size

1. Strong Magnetic Hold The magnets embedded within the V blocks offer a robust grip, ensuring that the workpiece stays in place. This strength is particularly important during high-speed machining processes, where any movement can lead to inaccuracies.

2. Ease of Adjustment Magnetic V blocks are designed for easy manipulation. Technicians can quickly adjust the position of the workpiece by releasing and reengaging the magnetic hold, improving efficiency when setting up for different operations.

3. Versatility Available in various sizes, magnetic V blocks can cater to a wide range of workpieces and operations. From flat surfaces to intricate shapes, these tools provide flexibility in securing items for a diverse array of machining tasks.

Applications Across Industries

Magnetic V blocks find applications in several industries, including

1. Manufacturing In production lines, these blocks are crucial for maintaining the precision of components during machining. They help in holding workpieces steady, enhancing the overall efficiency of the manufacturing process.

2. Metalworking Metalworkers utilize magnetic V blocks to inspect and grind components. Their ability to hold various shapes securely makes them invaluable in ensuring that critical tolerances and surface finishes are achieved.

3. Automotive and Aerospace Industries that require high levels of accuracy, such as automotive and aerospace, frequently rely on magnetic V blocks for engine component machining and inspections. The stability provided by these blocks ensures safety and compliance with stringent industry standards.

4. Education and Training In technical education and training programs, magnetic V blocks are often used to teach students about machining processes. Their ease of use and effectiveness make them excellent tools for hands-on learning.

Conclusion

Understanding the importance of size in magnetic V blocks is critical for anyone involved in machining and metalworking. Their role in providing stability and precision cannot be overstated, as they enhance productivity and ensure safety within various industrial applications. By selecting the appropriate size, technicians can optimize their workflow, ensuring superior results in their projects. As manufacturing processes continue to evolve, the significance of tools like magnetic V blocks remains a cornerstone of operational success.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS