জুলাই . 09, 2025 11:46 ফিরে তালিকায়

Features of Granite Inspection Block

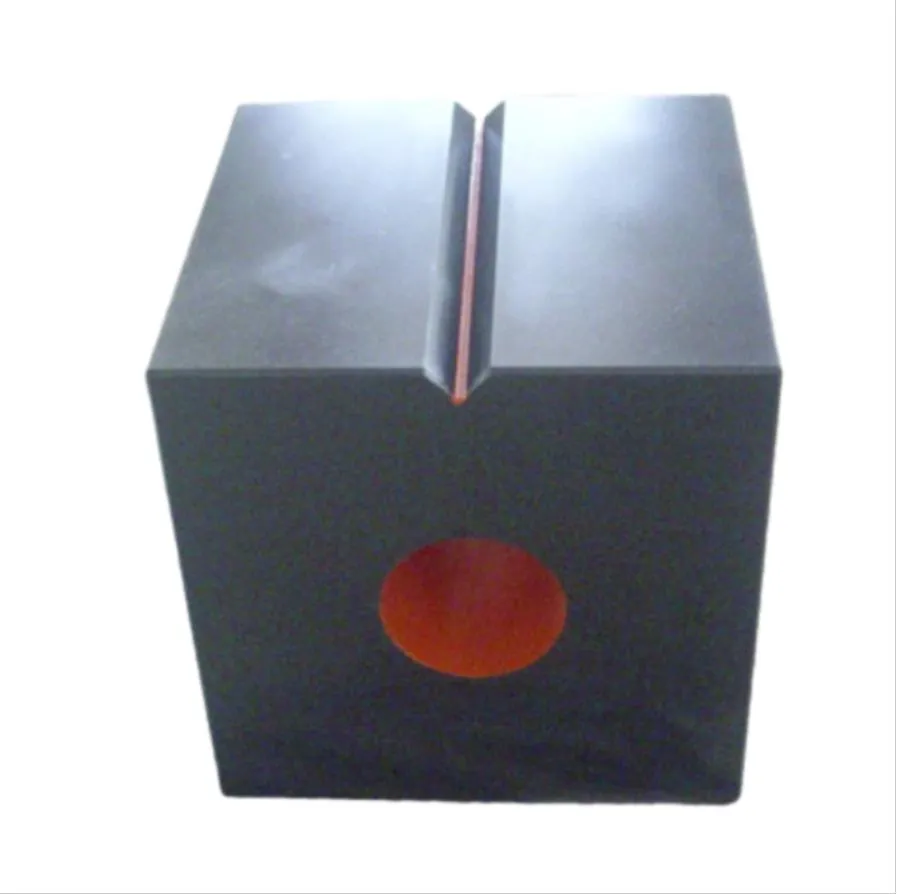

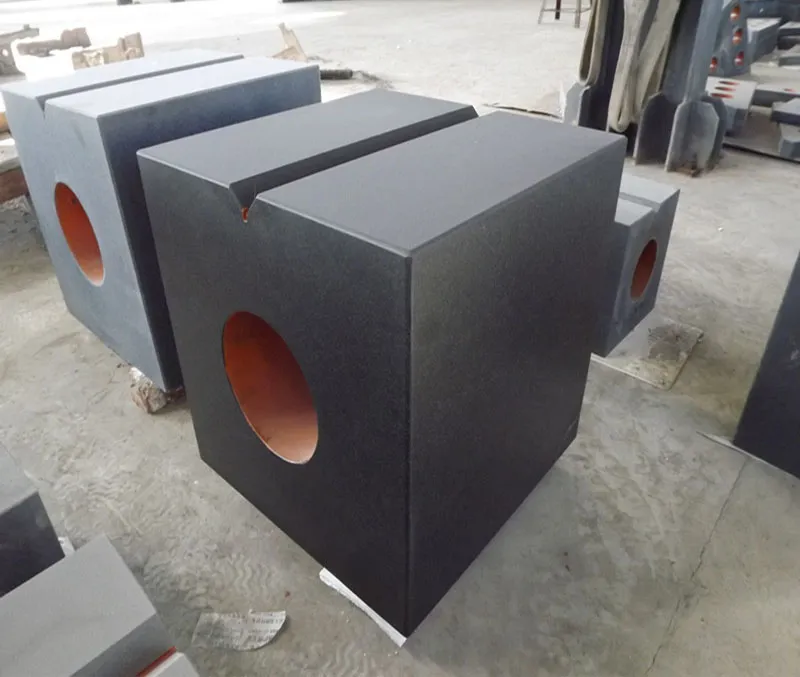

When precision measurement matters, granite inspection block products provide unmatched stability and accuracy. These premium square marble box instruments offer superior performance for metrology applications. Let's examine the key characteristics of these essential measurement tools.

Material Advantages of Granite Box

- Jinan blue stone construction provides exceptional durability for granite inspection block পণ্য

• Natural black luster with uniform texture ensures consistent performance in square marble box applications

• Non-rusting properties make granite box ideal for humid or corrosive environments

• Acid/alkali resistance maintains surface integrity of granite inspection block over time

• Non-magnetic characteristics prevent interference in sensitive measurement applications

|

Specification of granite square boxes |

Parallel Precision grade (μm) |

Planeness Precision grade (μm) |

Verticality Precision grade (μm) |

|

|

|

|

স্পেসিফিকেশন (মিমি) |

00 |

0 |

00 |

0 |

00 |

0 |

|

100×100×100 |

1 |

2 |

1 |

2 |

1 |

2 |

|

150×150×150 |

1.5 |

3 |

1 |

2 |

1.5 |

3 |

|

200×200×200 |

2 |

4 |

1.5 |

3 |

2 |

4 |

|

300×300×300 |

3 |

6 |

1.5 |

3 |

3 |

6 |

|

400×400×400 |

4 |

8 |

2 |

4 |

4 |

8 |

|

500×500×500 |

5 |

10 |

2.5 |

5 |

5 |

10 |

|

600×600×600 |

6 |

12 |

3 |

6 |

6 |

12 |

|

800×800×800 |

8 |

16 |

4 |

8 |

8 |

16 |

Precision Engineering of Square Marble Box

- Manual precision grinding creates ultra-flat surfaces on granite boxপণ্য

• Maintains high accuracy (typically 0.005mm) under normal working conditions

• Stable structure prevents deformation in granite inspection blockduring use

• HS70+ Shore hardness provides exceptional wear resistance for square marble box

• Minimal thermal expansion (4.6×10-6/°C) ensures dimensional stability

Technical Specifications of Granite Box

- Available sizes range from 100×100mm to 800×800mm granite inspection blockoptions

• Specific gravity of 2970-3070kg/m³ gives square marble boxsubstantial mass for stability

• Compressive strength of 245-254N/mm² makes granite box suitable for heavy loads

• Water absorption rate below 0.13% prevents moisture-related issues

• Standard packaging in plywood boxes protects granite inspection block during shipping

Industrial Applications of Square Marble Box

- Ideal reference surface for precision measurement in granite boxapplications

• Essential for quality control stations using granite inspection blocktechnology

• Perfect base for coordinate measuring machines with square marble box platforms

• Used in automotive/aerospace industries requiring granite box accuracy

• Critical for optical/laser measurement systems needing granite inspection block stability

Maintenance Guidelines for Granite Inspection Block

- Clean square marble boxsurfaces with mild detergent and soft cloth only

• Store granite boxin temperature-controlled environments when possible

• Use lifting equipment for large granite inspection block units to prevent damage

• Avoid direct impacts that could chip square marble box edges

• Regular calibration ensures ongoing accuracy of granite box surfaces

গ্রানাইট বক্স FAQS

Q: What are the key advantages of using a granite box in precision measurement tasks?

A: A granite box offers exceptional stability due to granite’s low thermal expansion and high density. Its smooth, non - magnetic surface resists wear and corrosion, ensuring long - term accuracy for tasks like aligning components or checking squareness in engineering setups.

Q: How does a granite inspection block differ from a standard granite box in application?

A: A granite inspection block is often a flat, precise surface for single - plane measurements (e.g., checking tool flatness). In contrast, a granite box has multiple orthogonal surfaces, making it ideal for 3D squareness, parallelism checks, and holding workpieces in multi - directional precision setups.

Q: Can a square marble box replace a granite box in industrial metrology?

A: While both use stone (marble/granite) for precision, a square marble box may be less durable than a granite box in heavy - use environments. Granite’s higher hardness and abrasion resistance make it better for long - term, high - precision industrial metrology, though marble works for lighter, less abrasive tasks.

Q: What maintenance do granite box and granite inspection block require?

A: Clean them regularly with a lint - free cloth and mild cleaner to remove debris. Avoid dropping or impact (granite is brittle). Re - calibrate periodically (per industry standards, like annually) to ensure flatness, parallelism, and squareness stay within tolerance.

Q: How to choose between a granite box and a square marble box for a workshop?

A: Consider your needs: if you need multi - surface, heavy - duty precision (e.g., machining setups), a granite box is better. For lighter, lower - cost, single - plane or less abrasive tasks (e.g., small - part inspection), a square marble box can suffice, balancing cost and basic precision.

Step into the world of Storaen (Cangzhou) International Trading Co., where manufacturing meets mastery! Hailing from Botou, China’s industrial epicenter, we're not just a company—we're architects of precision. Our diverse portfolio, from robust cast iron welding platforms to intricate measuring tools and reliable valves, is a testament to our commitment to quality.

Think of us as the alchemists of industry, transforming raw materials into products that redefine durability. Our strategic location fuels our innovation, while our dedication to sustainability paves the way for a greener future. At Storaen, we don’t just meet expectations—we shatter them. Join us at www.strmachinery.com and discover industrial solutions that are truly in a league of their own.

-

thread-plug-gauge-our-promise-of-measurement-excellenceখবরAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyখবরAug.22,2025

-

check-valve-types-for-high-rise-buildingsখবরAug.22,2025

-

water-control-valve-for-irrigation-systemsখবরAug.22,2025

-

gate-valve-with-soft-seal-technologyখবরAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsখবরAug.22,2025

সংশ্লিষ্ট পণ্য