নভে. . 16, 2024 15:34 Back to list

Guide to Quality Assessment for Cast Iron Products and Inspection Standards

Understanding Cast Iron Inspection Table A Guide

Cast iron has been a critical material in various industries, especially in construction, automotive, and manufacturing. Its durability, resistance to wear, and versatility make it an ideal choice for a plethora of applications. However, to ensure the quality and reliability of cast iron products, rigorous inspection is essential. This article delves into the importance of cast iron inspection tables and the methodologies involved.

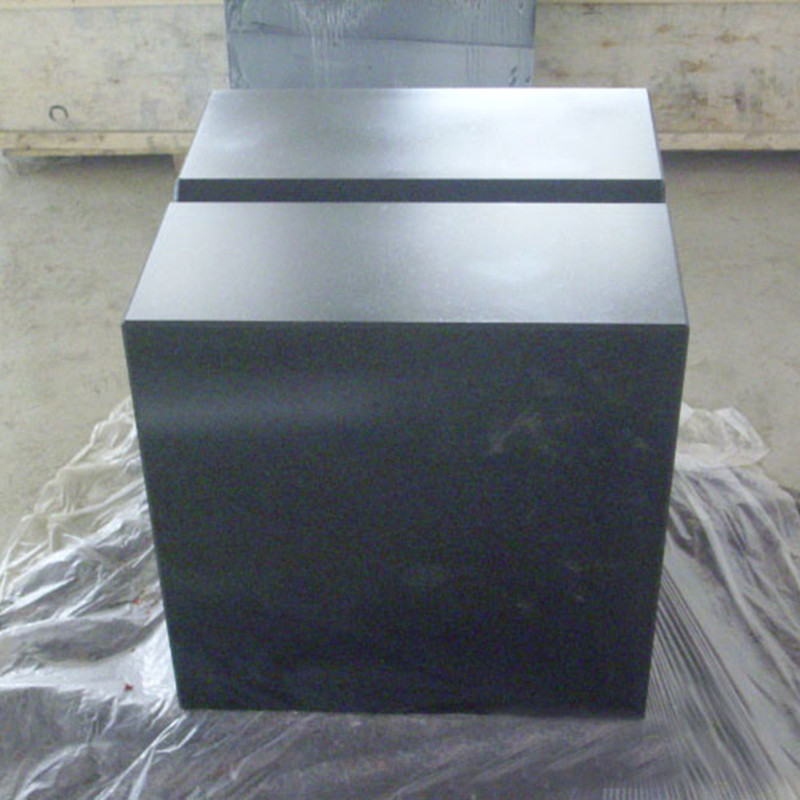

What is a Cast Iron Inspection Table?

A cast iron inspection table is a sturdy, flat surface used for measuring and examining various components made of cast iron. These tables serve as a benchmark for precision measurements, ensuring that the cast iron pieces meet industry standards and specifications. Typically made of high-quality cast iron, these tables are designed to remain stable and free from distortion, providing an accurate reference point for inspections.

Importance of Inspection

The inspection process is vital for several reasons

1. Quality Assurance By employing a cast iron inspection table, manufacturers can ensure the cast iron components conform to the required tolerances and specifications. This not only enhances the product's quality but also minimizes the risk of defects.

2. Cost Efficiency Identifying flaws during the inspection stage can save manufacturers significant costs associated with defects that only become apparent later in the production process or post-deployment.

3. Safety Standards Many industries require stringent safety regulations for their products. Regular inspections help ensure that cast iron components will not fail under operational stresses, thereby protecting both the equipment and its operators.

cast iron inspection table

4. Longevity Inspections can also identify wear and tear over time, helping in the maintenance of equipment. Regular checks contribute to the longer lifespan of components, saving on future replacement costs.

Common Inspection Methods

1. Visual Inspection This is the first step in the inspection process. Inspectors look for visible defects such as cracks, chips, or surface inconsistencies.

2. Dimensional Measurement Using precision tools like calipers or micrometers, inspectors measure various dimensions of the cast iron parts to ensure they meet the specified requirements.

3. Non-Destructive Testing (NDT) Techniques such as ultrasonic testing or magnetic particle inspection are employed to detect internal flaws without damaging the component.

4. Hardness Testing The hardness of the cast iron is tested to ensure it meets the necessary specifications for its intended use. This can involve methods such as Rockwell or Brinell hardness tests.

5. Chemical Composition Analysis Inspectors may analyze samples to determine the exact composition of the cast iron, ensuring it meets industry standards for alloying elements.

Conclusion

In conclusion, a cast iron inspection table plays a pivotal role in the manufacturing and maintenance of cast iron components. By ensuring thorough inspections, manufacturers can uphold high standards of quality, safety, and performance. The detailed examination methods employed alongside the inspection tables lend to the durability and reliability of cast iron products in various applications. Emphasizing rigorous inspection protocols ultimately leads to enhanced customer satisfaction and product longevity.

-

Rising Demand for Corrosion-Resistant Metal Valves in Wholesale MarketsNewsMay.30,2025

-

Revolutionizing Industrial Workholding for Fabrication Table ClampsNewsMay.30,2025

-

Precision Measurement: Plug Gauges in Industrial Quality ControlNewsMay.30,2025

-

Material Selection and Durability in Heavy-Duty Welding Table WorkbenchesNewsMay.30,2025

-

Durability and Maintenance of Granite Fabrication TablesNewsMay.30,2025

-

Precision in Measurement: Why a Quality Inspection Platform MattersNewsMay.29,2025

Related PRODUCTS