ное. . 19, 2024 23:47 Back to list

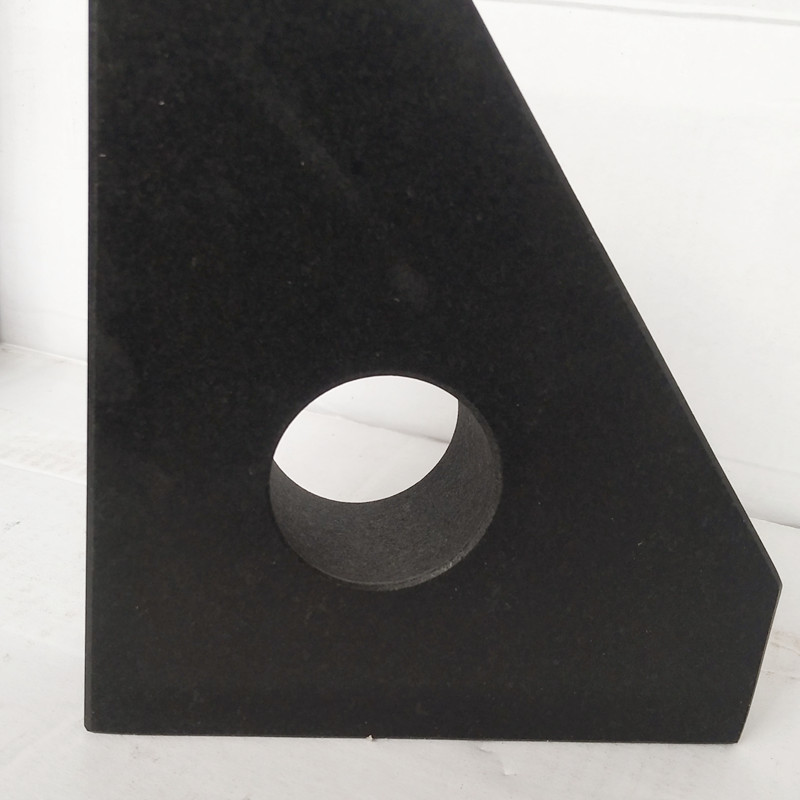

full flow check valve

Understanding Full Flow Check Valves Mechanisms and Applications

In various industrial applications, the effective management of fluid flow is crucial. One of the key components used in fluid systems is the check valve. Among the various types, the full flow check valve stands out due to its design and functionality that allows for the uninterrupted flow of liquids or gases while preventing backflow. This article delves into the mechanics, advantages, and applications of full flow check valves, highlighting their importance in modern infrastructure.

What is a Full Flow Check Valve?

A check valve, in general, is a device that permits the flow of fluid in one direction while preventing its reverse flow. The full flow check valve is designed to allow fluid to flow freely with minimal resistance, helping maintain system efficiency. The design of these valves is such that they provide a larger passage for the fluid, significantly reducing pressure drops compared to traditional check valves. This optimization is vital in applications where pressure conservation is critical.

Mechanism of Operation

The operational mechanics of a full flow check valve primarily involve a movable element known as a disc, ball, or flap that opens with the flow of the fluid. When the fluid moves in the desired direction, it pushes the disc off its seat, allowing the flow to pass through. Conversely, when flow attempts to reverse, the disc automatically returns to its seat, effectively blocking any backflow.

This mechanism can be influenced by the fluid's velocity, pressure, and gravity, depending on the specific installation and operation conditions. One of the advantages of full flow check valves is their ability to respond quickly to changes in flow direction, thus securing the system against backflow consequences such as contamination, pressure spikes, and water hammer effects.

Advantages of Full Flow Check Valves

1. Minimal Pressure Drop One of the primary advantages is that they feature a larger flow area, resulting in minimal pressure drops compared to other types of check valves. This efficiency is essential in systems where maintaining pressure is crucial for operational effectiveness.

full flow check valve

2. Durability and Reliability Full flow check valves are generally constructed from durable materials that can withstand harsh operating conditions, including high temperatures and corrosive environments. This durability enhances their reliability and longevity.

3. Low Maintenance Requirements With fewer moving parts and robust construction, these valves often require less maintenance than traditional check valves. This is particularly beneficial in automated systems where reducing downtime is critical.

4. Versatile Applications Full flow check valves can be used in a wide range of applications, from water and wastewater management to oil and gas, chemical processing, and HVAC systems. Their adaptability makes them a preferred choice in various industries.

Applications of Full Flow Check Valves

- Water Treatment and Distribution In municipal water systems, full flow check valves are used to prevent backflow and protect the quality of potable water. - Pumping Systems In various pumping applications, these valves help maintain system efficiency by ensuring fluid flows in the desired direction, preventing reverse flow during pump shutdowns.

- Oil and Gas In oil and natural gas pipelines, these valves prevent backflow that could lead to contamination and operational hazards.

- Cooling Systems In HVAC systems, full flow check valves are crucial for maintaining the efficiency of cooling cycles and preventing backflow that could disrupt system operations.

Conclusion

Full flow check valves are essential components in many fluid management systems, offering several advantages over traditional check valves, including reduced pressure drops, enhanced durability, and low maintenance needs. Their reliability and versatility make them a valuable asset in industrial applications ranging from water distribution to chemical processing. Understanding the mechanics and benefits of these valves can help engineers and technicians optimize their systems for better performance and longevity. As industries continue to evolve, the role of full flow check valves will remain a significant aspect of effective fluid control.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS