окт. . 14, 2024 14:54 Back to list

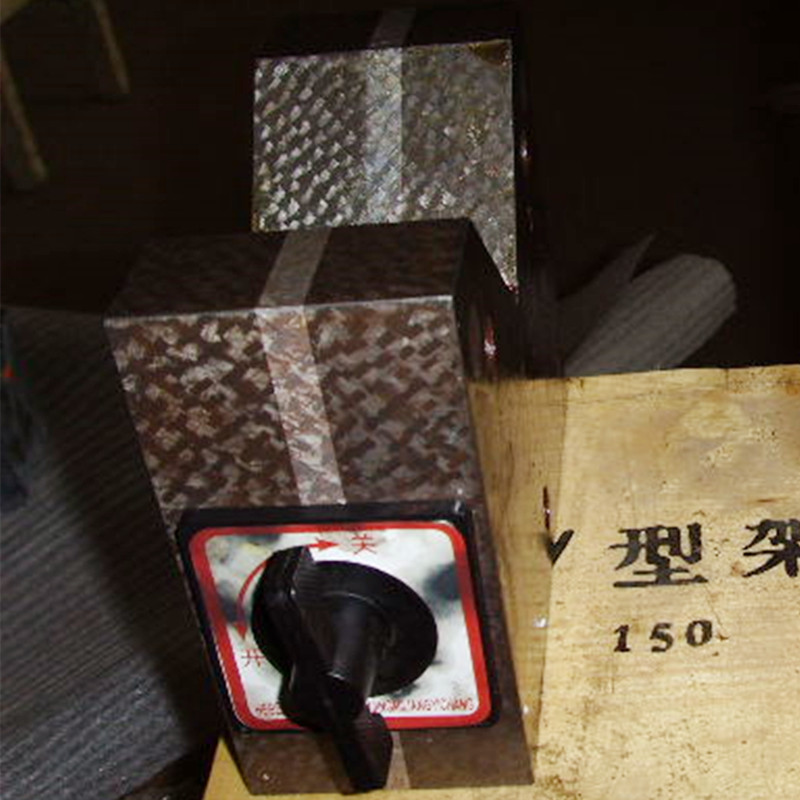

butterfly valve

Understanding Butterfly Valves Their Importance and Applications

Butterfly valves are pivotal components in various industrial applications, serving as essential devices for controlling the flow of fluids. Their design is characterized by a rotating disc that regulates the passage of fluids through the valve, effectively opening or closing the flow with minimal resistance. This article explores the construction, functionality, applications, and benefits of butterfly valves.

Construction and Operation

The butterfly valve consists of a few key components the body, disc, stem, and actuator. The body is the main part of the valve that houses the internal mechanisms, typically made from materials such as cast iron, stainless steel, or plastic, depending on the application. The disc is a circular plate that pivots around a central axis and is the part that opens or closes the valve. Attached to the disc is a stem, which connects to an actuator.

Actuators can be manual, pneumatic, or electric, allowing the valve to be operated remotely or automatically. When the actuator turns the stem, the disc rotates, permitting or restricting the flow of fluid. When in the fully open position, the disc is parallel to the flow, leading to minimal pressure loss and friction, which makes butterfly valves efficient for large flows.

Types of Butterfly Valves

There are several types of butterfly valves designed for various applications. The most common include

1. Concentric Butterfly Valves These have the disc and seat in a single plane and are typically used in low-pressure applications. 2. Eccentric Butterfly Valves In these valves, the disc is positioned off-center, allowing for better sealing and is suitable for higher-pressure applications. 3. Double Eccentric Butterfly Valves Featuring two offsets, these valves reduce the friction between the disc and the seat, resulting in improved sealing and longer life. 4. Triple Eccentric Butterfly Valves These are designed for high-temperature and high-pressure applications, utilizing a unique design that minimizes wear and tear.

butterfly valve

Applications

Butterfly valves are widely used across various industries, including

- Water and Wastewater Treatment They control the flow of water in treatment plants and distribution systems. - Oil and Gas Used in pipelines for fluid control, they are crucial in preventing leaks and maintaining system integrity. - HVAC Systems They regulate air and water flow in heating, ventilation, and air conditioning systems. - Food and Beverage Industry Stainless steel butterfly valves are used to maintain hygiene and control processes in food production.

Advantages

The advantages of butterfly valves make them a popular choice among engineers and industry experts

1. Compact Design Their compact size makes them suitable for applications with limited space. 2. Light Weight Butterfly valves are lighter than other valve types, reducing the load on piping systems. 3. Quick Operation The quarter-turn operation allows for fast valve actuation, enhancing efficiency. 4. Low Pressure Drop Their design provides excellent flow characteristics with minimal pressure loss. 5. Versatile Butterfly valves can handle a wide range of fluids, including gases, liquids, and slurries, making them adaptable to various applications.

Conclusion

In summary, butterfly valves are integral to modern industrial systems, providing efficient flow control across various applications. Their simple design, combined with their versatility and effectiveness, underscores their importance in many sectors. As industries evolve and seek innovative solutions for fluid management, butterfly valves continue to be a reliable choice, ensuring operational efficiency and safety. Understanding their construction, types, and applications is essential for anyone involved in the design and management of fluid systems.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS