Butterfly Valves

Съдържание на продукта

Centerline butt-clamp soft seal butterfly valve, double eccentric flanged butterfly valve compact structure, 90 ° rotary switch easily, reliable sealing, long service life, is widely used in water mills, power plants, steel mills, papermaking, chemical industry, catering and other systems of water supply and drainage, as a regulator and cut-off use.

Описание на продукта

Butterfly valve, referred to as butterfly valve (butterfly valve), refers to the closing member (valve flap or butterfly plate) for the disk, rotating around the valve axis to achieve the opening and closing of a kind of valve, in the pipeline is mainly used for cutting off and throttling. Butterfly valve opening and closing member is a disc-shaped butterfly plate, rotating around its own axis in the valve body, so as to achieve the purpose of opening and closing or regulation. Butterfly valve full open to full closed is usually less than 90 °, butterfly valve and butterfly stem itself does not have the ability to self-locking, in order to the positioning of the butterfly plate, to be installed on the valve stem worm gear reducer. The use of worm gear reducer, not only can make the butterfly plate with self-locking ability, so that the butterfly plate stops in any position, but also improve the operating performance of the valve.

The characteristics of industrial special butterfly valve can withstand high temperature, the applicable pressure range is also higher, the valve nominal diameter is large, the valve body is made of carbon steel, the sealing ring of the valve plate is made of metal ring instead of rubber ring. Large high-temperature butterfly valves are made of welded steel plate and are mainly used for high-temperature medium flue gas ducts and gas pipelines.

Three Core Technical Designs of High-Performance Butterfly Valves

STORAEN’s butterfly valves redefine industrial flow control through innovative engineering, combining precision sealing, material resilience, and smart actuation to deliver unmatched performance in diverse applications. As a leading provider of butterfly valve types and solutions, our designs address the critical challenges of leakage, wear, and operational efficiency. Here’s how three core technologies set our butterfly valves apart.

1. Eccentric Sealing Systems for Zero-Leak Performance

The heart of our high-performance butterfly valve lies in its advanced eccentric designs, eliminating the common leakage issues plaguing traditional valves:

Double Eccentric Geometry: An offset disc axis (1st eccentricity) and seat angle (2nd eccentricity) create a “line-contact” seal when closed, reducing friction by 40% compared to concentric models. This design ensures bubble-tight shutoff for gases and liquids, even at high pressures (up to PN16.0MPa), making it ideal for butterfly valve applications in chemical pipelines and steam systems.

Triple Eccentric Innovation: For extreme conditions (450°C+ flue gas or abrasive media), our triple-eccentric valves add a third offset (disc face tilt), allowing metal-to-metal sealing without seat wear. This technology surpasses globe valve limitations in high-temperature isolation, ensuring long-term reliability in power plant exhaust systems.

2. Material Science for Harsh Environment Resilience

We engineer valve components to withstand the toughest working condition, matching butterfly valve types to specific media demands:

Body & Disc Materials: Choose from HT300 cast iron (cost-effective for water/gas, -10°C~200°C), WCB carbon steel (heavy-duty industrial, -29°C~425°C), or 316L stainless steel (corrosion-resistant for chemicals, -40°C~450°C). Our 6-inch and 4-inch butterfly valves feature thickened disc ribs to prevent deformation under high flow velocity, outperforming standard designs by 25% in cycle life.

Seal Combinations: Soft seals (NBR/EPDM) offer ≤0.1mm leakage tolerance for water and wastewater, while hard seals (stainless steel + graphite) handle particle-laden media without erosion, critical for mining slurry or cement plants.

3. Intelligent Actuation for Precision Control

Our butterfly valves integrate advanced mechanisms to enhance operational efficiency and safety:

Worm Gear Reducers: Standard on manual valves, these provide 5:1 torque multiplication and self-locking functionality, enabling easy 90° operation even for 12-inch diameters while eliminating backdrive risks in vertical pipelines.

Automation-Ready Design: Pneumatic, electric, or hydraulic actuators mount directly to ISO 5211 top flanges, supporting fail-safe positions (open/close/hold) and 4-20mA feedback for PLC integration. This makes our valves ideal for automated processes, reducing response time by 30% compared to legacy globe valve systems.

Elevate Your Flow Control with STORAEN

From water distribution to high-temperature industrial processes, our butterfly valves deliver the precision, durability, and adaptability your system demands. With innovative sealing, premium materials, and smart actuation, we’ve transformed the butterfly valve from a simple shutoff device into a high-performance control solution. Explore our butterfly valves for sale today and experience the difference that engineering excellence makes—because in flow control, performance is everything.

STORAEN Butterfly Valves: Custom Solutions and Quality Assurance

STORAEN redefines industrial flow control with tailor-made butterfly valve solutions and uncompromising quality standards, ensuring every valve meets your unique operational demands. From material selection to performance certification, our butterfly valve types combine engineering flexibility with rigorous quality assurance—here’s how we deliver precision for your specific needs.

Customization: Engineered to Your Exact Specifications

1. Tailored Sizing & Configurations

Covering DN40 to DN1200, our 4-inch butterfly valve and 6-inch butterfly valve models (and beyond) adapt to pipe networks of any scale. Non-standard sizes? We craft custom diameters for unique installations, from compact HVAC systems to massive industrial pipelines.

Choose from wafer, lug, flanged, or welded connections to match ASME, DIN, or JIS standards—eliminating adapter hassles in global projects.

2. Material & Seal Optimization

Body Materials: Select HT300 cast iron (water/gas), WCB carbon steel (heavy industry), or 316L stainless steel (corrosion resistance) to suit media from -40°C to 450°C.

Seal Types: Soft seals (NBR/EPDM) for water/wastewater (≤0.1mm leakage), or hard metal seals (stainless steel + graphite) for high-temperature/flue gas—outperforming globe valve durability in abrasive conditions.

3. Actuation & Functionality

Manual (worm gear), pneumatic, electric, or hydraulic actuators with ISO 5211 mounting ensure precise control. Add fail-safe mechanisms (air-to-open/close) or 4-20mA feedback for automated processes.

Specialized designs: Cryogenic valves (-196°C), high-vacuum models, or fire-safe configurations for safety-critical applications.

Uncompromising Quality: From Design to Delivery

1. Rigorous Testing Regime

Hydrostatic Tests: 1.5x pressure rating for shells, 1.1x for seats, verifying zero leakage.

Cycle Testing: 5,000+ operations for soft seals, 10,000+ for hard seals—proving durability surpassing industry norms.

Material Traceability: Every component includes a mill certificate, ensuring compliance with chemical resistance and temperature requirements.

2. Warranty & After-Sales Support

1-year warranty covers seal performance and mechanical defects, with 24/7 technical support for installation, maintenance, or troubleshooting.

Spare parts availability: Quick delivery of replacement seats, discs, or actuators to minimize downtime—ideal for customers purchasing butterfly valves for sale in bulk.

Why Choose STORAEN for Custom Butterfly Valves?

Application Expertise: Whether you need a concentric butterfly valve for water treatment or a triple-eccentric model for petrochemical plants, our engineers align butterfly valve types and applications to your exact process parameters.

Total Cost Efficiency: Customized solutions reduce over-engineering costs, while durable designs cut maintenance by 30% compared to generic valves.

Elevate Your System with Tailored Precision

Don’t settle for off-the-shelf when your operations demand excellence. STORAEN’s custom butterfly valves—backed by rigorous quality assurance—deliver the performance, reliability, and adaptability your projects deserve. Explore our butterfly valves for sale today and discover how tailored engineering transforms flow control.

Чертеж на детайл на продукта

Product Classification

Classification by structure form

(1)Center Sealed Butterfly Valve

(2)Single Eccentric Sealed Butterfly Valve

(3) double eccentric seal butterfly valve

(4) three eccentric seal butterfly valve

According to the sealing surface material classification

(1) soft seal butterfly valve:

1) sealing vice by non-metallic soft material to non-metallic soft material composition.

2) sealing vice by metal hard material to non-metallic soft material composition.

(2) metal hard seal butterfly valve: sealing vice by metal hard material to metal hard material composition.

Classification by sealing form

(1) forced seal butterfly valve

1) elastic seal butterfly valve. Seal specific pressure by the valve plate extrusion valve seat when the valve is closed, the valve seat or valve plate elasticity generated.

2) external torque seal butterfly valve. Sealing pressure is generated by the torque applied to the valve shaft.

(2) Pressurized seal butterfly valve. The sealing specific pressure is generated by the valve seat or valve plate on the poppet sealing element filling pressure.

(3) Automatic sealing butterfly valve. Sealing pressure is automatically generated by the medium pressure.

Classification by working pressure

(1) vacuum butterfly valve. Working pressure below the standard pile of atmospheric calendar butterfly valve.

(2) low pressure butterfly valve. Nominal pressure PN <1.6MPa butterfly valve.

(3) medium pressure butterfly valve. Nominal pressure PN 2.5 - 6.4MPa butterfly valve.

(4) high-pressure butterfly valve. Nominal pressure PN 10.0 - 80.0MPa butterfly valve.

(5) ultra-high pressure butterfly valve. Nominal pressure PN>100MPa butterfly valve.

Classification by operating temperature

(1) high temperature butterfly valve. t>450 C butterfly valve

(2)Medium temperature butterfly valve. 120 C<t<450 ℃ butterfly valve.

(3) Normal temperature butterfly valve. A 40 C<t<; 120 C butterfly valve.

(4) Low temperature butterfly valve. A butterfly valve of 100 <t< a 40 C.

(5) Ultra-low temperature butterfly valve. t< a 100 C butterfly valve.

Classification by connection

(1) Butterfly valve.

The butterfly plate of the butt-clamp butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, the angle of rotation between 0 ° - 90 °, rotated to 90 °, the valve is fully open state.

Butterfly valve is simple in structure, small in size and light in weight, and consists of only a few parts. And only need to rotate 90 ° can quickly open and close, simple operation, at the same time the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics. Butterfly valve has two types of sealing: elastic seal and metal seal. Elastic seal valve, the seal can be set in the valve body or attached to the butterfly plate around.

(2) flanged butterfly valve.

Flanged butterfly valve for vertical plate structure, the valve stem for the integral metal hard seal valve sealing ring for flexible graphite plate and stainless steel plate composite structure, mounted on the valve body, butterfly plate sealing surface surfaces welded stainless steel. The sealing ring of the soft seal valve is made of nitrile rubber, which is installed on the butterfly plate.

(3)Lug type butterfly valve.

(4) Welded butterfly valve.

Welded butterfly valve is a non-closed type butterfly valve, widely used in building materials, metallurgy, mining, electric power and other production processes, the medium temperature ≤ 300 ℃ nominal pressure of 0.1Mpa pipeline, used to connect, open and close or adjust the amount of media.

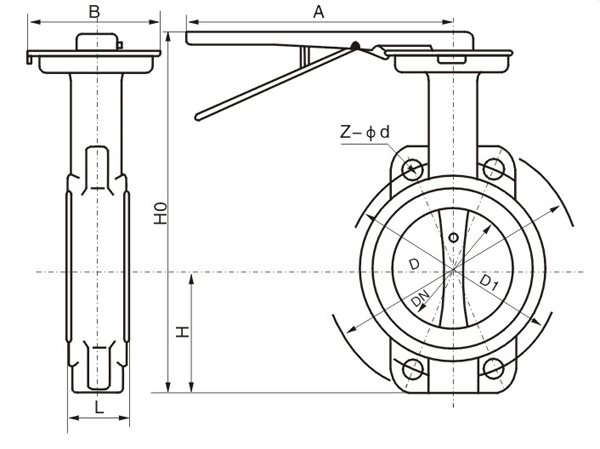

Clamped soft seal butterfly valve main shape connection size Unit: mm

Параметър на продукта

|

DN |

L |

H |

HO |

A |

B |

0.6MPa |

1.0MPa |

1.6MPa |

|||

|

DO |

n-d |

DO |

n-d |

DO |

n-d |

||||||

|

50 |

43 |

63 |

235 |

270 |

110 |

110 |

4-14 |

125 |

4-18 |

125 |

4-18 |

|

65 |

46 |

70 |

250 |

270 |

110 |

130 |

4-14 |

145 |

4-18 |

145 |

4-18 |

|

80 |

46 |

83 |

275 |

270 |

110 |

150 |

4-18 |

160 |

8-18 |

160 |

8-18 |

|

100 |

52 |

105 |

316 |

270 |

110 |

170 |

4-18 |

180 |

8-18 |

180 |

8-18 |

|

125 |

56 |

115 |

340 |

310 |

110 |

200 |

8-18 |

210 |

8-18 |

210 |

8-18 |

|

150 |

56 |

137 |

376 |

310 |

110 |

225 |

8-18 |

240 |

8-22 |

240 |

8-22 |

|

200 |

60 |

164 |

430 |

353 |

150 |

280 |

8-18 |

295 |

8-22 |

295 |

8-22 |

|

250 |

68 |

206 |

499 |

353 |

150 |

335 |

12-18 |

350 |

12-22 |

355 |

12-26 |

|

300 |

78 |

230 |

570 |

380 |

150 |

395 |

12-22 |

400 |

12-22 |

410 |

12-26 |

What is a Butterfly Valve Used For?

A butterfly valve is a type of quarter-turn valve that utilizes a rotating disc to regulate fluid flow. Its design incorporates various features that make it suitable for specific applications in various industries, including water supply, wastewater treatment, chemical processing, and HVAC systems. Understanding the functionalities and advantages of a butterfly valve can help you make informed decisions on its use in different scenarios.

One primary purpose of a butterfly valve is to control the flow of liquids and gases. The disc within the valve pivots around a central axis, allowing for quick and efficient operation. This quarter-turn mechanism is particularly advantageous when rapid adjustments to flow rates are needed. For instance, in water treatment plants or industrial applications where precise control is crucial, a butterfly valve can serve as an effective solution.

Furthermore, butterfly valves are recognized for their lightweight and compact design. Compared to other types of valves, they occupy less space, making them ideal for installations in tight spaces or when weight considerations are critical. Whether in pipelines or confined areas, a butterfly valve's minimalist design allows for versatility without sacrificing functionality.

Another significant application of a butterfly valve is in system isolation. By fully closing the disc, the valve creates a tight seal that prevents fluid flow. This is particularly useful in maintenance scenarios where isolating sections of a pipeline is necessary. The ability to quickly and reliably cut off flow makes butterfly valves an essential component in controlling systems and ensuring safety in various industrial processes.

In summary, a butterfly valve is employed in numerous applications to regulate flow, isolate systems, and enhance operational efficiency. Its compact design, quick operation, and reliability make it a popular choice in many industries. Understanding what a butterfly valve is used for will enable you to appreciate the critical role it plays in fluid control and management. Whether you're involved in engineering, maintenance, or industrial design, having a solid grasp of butterfly valve applications will serve you well in your professional endeavors.

The Advantages of Butterfly Valves

One significant advantage of butterfly valves is their compact design. Unlike traditional valves that tend to be bulky, butterfly valves consist of a simple disc mounted on a shaft. This streamlined structure allows for installation in tight spaces, making them an ideal option for projects with limited room for equipment. Additionally, their lightweight nature reduces the overall weight of piping systems, leading to easier handling and installation.

Another critical benefit of butterfly valves is their quick operation. The design facilitates rapid opening and closing, with a rotation of only 90 degrees required for full movement. This feature is particularly valuable in applications where timely control of flow is paramount, such as in water treatment facilities or chemical processing plants. The swift responsiveness of butterfly valves contributes to enhanced operational efficiency and reduced downtime.

Moreover, butterfly valves offer excellent flow regulation. When partially opened, these valves can create a streamlined flow path while effectively controlling the media passing through. This characteristic is essential in applications where precise flow management is crucial, allowing for consistent system performance.

Butterfly valves also exhibit durability and low maintenance needs. Constructed from robust materials like stainless steel or PVC, they are resistant to corrosion, making them suitable for various substances, including aggressive chemicals and corrosive environments. Their simple mechanism reduces the likelihood of mechanical failure, further minimizing maintenance requirements and operational costs.

Finally, the adaptability of butterfly valves makes them suitable for diverse applications across different industries. From HVAC systems to water supply and wastewater treatment, these valves can handle a wide range of fluids, enhancing their utility across multiple fields.

What Is the Difference Between a Gate Valve and a Butterfly Valve?

Operating Mechanism

The primary difference between gate valves and butterfly valves lies in their design and operating mechanisms. A gate valve utilizes a linear motion to lift or lower a gate to control the flow. This mechanism is ideal for on-off control but does not perform well in throttling applications. Conversely, a butterfly valve comprises a rotating disc that pivots around a central shaft to regulate flow. This design allows for quick operation and is particularly effective in throttling.

Flow Control and Efficiency

Another critical distinction is the flow characteristics. Butterfly valves are known for their ability to provide a consistent flow rate with minimal pressure drop. This efficiency is highly advantageous in large-volume applications and where space is limited. In contrast, gate valves are less efficient in throttling and can create turbulence, leading to a performance deficit in high-flow scenarios.

Space and Weight Considerations

Butterfly valves are generally more compact and lighter than gate valves. This space-saving design makes butterfly valves suitable for installation in tight spaces, where traditional gate valves may prove cumbersome. The reduced weight of butterfly valves simplifies handling during installation and maintenance.

Application Suitability

Both valve types have specific applications where they excel. Gate valves are typically used in applications requiring minimal pressure loss and where full isolation is paramount. Conversely, butterfly valves are favored in systems requiring quick operation and frequent flow adjustments, making them ideal for HVAC systems, water distribution, and wastewater treatment.

What Are the Three Types of Butterfly Valves?

1. Concentric Butterfly Valves

Concentric butterfly valves are characterized by their simple design, where the disc is aligned eccentrically with the valve body. In this configuration, the disc rotates around an axis that lies parallel to the flow of fluid. Concentric butterfly valves are primarily used in low-pressure applications, making them ideal for water and wastewater treatment. Their straightforward design allows for efficient flow control and minimal pressure drop, which ensures optimal performance in various settings.

2. Eccentric Butterfly Valves

Eccentric butterfly valves, also known as high-performance butterfly valves, feature a unique design that allows the disc to be offset from the valve seat. This design improves sealing capabilities and reduces wear on the valve components. Eccentric butterfly valves are well-suited for more demanding applications, including those involving higher pressures and temperatures. They excel in services such as the handling of slurries, corrosive fluids, and other challenging media, ensuring long-lasting operation and reliability.

3. Double Eccentric Butterfly Valves

Double eccentric butterfly valves, or triple offset butterfly valves, take the design of eccentric valves a step further. With two offsets—one for the disc's rotation and another for the sealing surface—these valves offer enhanced performance, particularly in demanding conditions. The double eccentric design results in lower friction between the disc and seat, allowing for a tight seal without the wear associated with traditional valve designs. They are the ideal choice for high-pressure, high-temperature applications and frequently find use in industries such as oil and gas, power generation, and pharmaceuticals.

Свързани ПРОДУКТИ

СВЪРЗАНИ НОВИНИ

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.