Каст . 18, 2024 12:37 Back to list

Spline Gauge Measurement for Precision Engineering Applications and Manufacturing

Understanding Spline Gauges A Comprehensive Overview

Spline gauges, a critical tool in precision engineering and manufacturing, play a fundamental role in ensuring the accuracy and quality of components that feature spline profiles. A spline is a mechanical joint used to transmit torque between two parts. This is particularly prevalent in various applications such as automotive, aerospace, and industrial machinery. This article delves into what spline gauges are, their applications, and their significance in precision measurement.

At its core, a spline gauge is a precision instrument designed to measure the dimensions and geometrical characteristics of splines. Typically made from high-quality steel or other durable materials, these gauges are engineered to provide accurate readings of tooth spacing, profile depth, and overall spline dimensions. The design of a spline can vary greatly, featuring different forms such as involute, square, or keyway splines, which influence the selection and construction of the gauge.

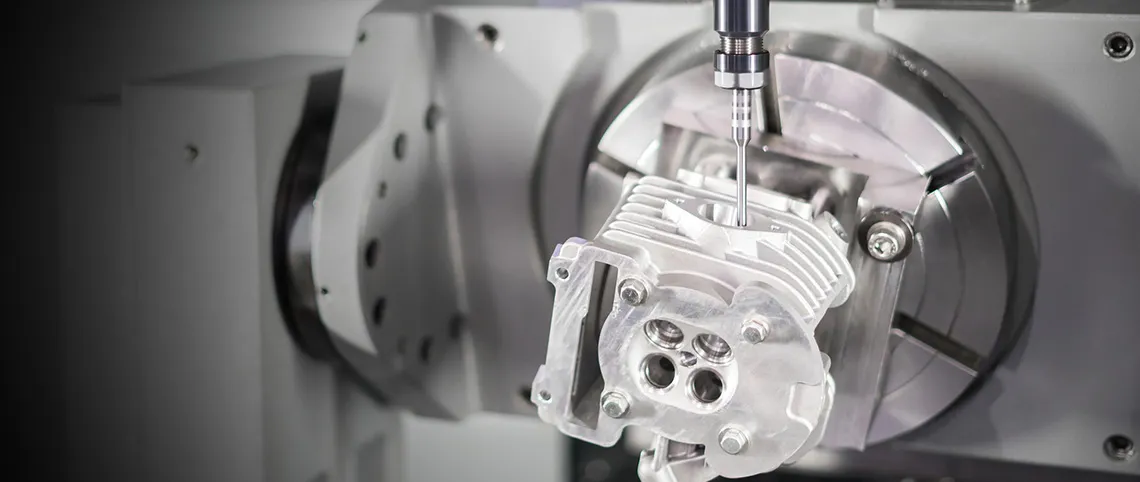

One of the primary applications of spline gauges is in the automotive industry

. Here, they are used to ensure that the splines on shafts and hubs fit together perfectly, allowing for the efficient transfer of power. Any misalignment or manufacturing defect could lead to mechanical failure, which underscores the importance of precise measurements. Spline gauges help manufacturers control the quality of their products, ultimately ensuring safety and reliability.spline gauge

In addition to automotive applications, spline gauges are also essential in manufacturing environments that produce equipment for industrial machinery. Properly fitted spline joints are crucial in assemblies that undergo high levels of stress and torque. By utilizing spline gauges, engineers and machinists can achieve the tight tolerances required for these applications, thus enhancing the durability and functioning of the machinery.

The significance of spline gauges extends beyond the industries mentioned. In the realm of aerospace, for instance, these gauges are invaluable for measuring parts that undergo rigorous performance testing. Even slight discrepancies in the dimensions of splines could lead to catastrophic failures in flight, hence the uncompromising standards of measurement upheld by aerospace manufacturers.

Moreover, spline gauges come in various types, each catering to specific spline designs and applications. Fixed gauges give a direct measurement, while adjustable gauges allow for flexibility in accommodating different spline sizes. Electronic spline gauges are also available and provide digital readings, which enhance the ease and accuracy of measurement.

In conclusion, spline gauges are indispensable tools in the world of precision engineering. Their ability to ensure the accuracy of spline dimensions directly influences the performance and safety of mechanical systems across various industries. As technology continues to evolve, so too will the design and application of spline gauges, making them even more crucial in the quest for precision in manufacturing. Understanding the role of these gauges is pivotal for engineers and manufacturing professionals committed to excellence and reliability in their work.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS