снеж . 12, 2024 18:33 Back to list

precision tool and gage

Precision Tools and Gages Essential Instruments for Quality Control

In the modern manufacturing landscape, precision tools and gages play a crucial role in ensuring product quality and reliability. As industries evolve and demand for higher standards intensifies, the need for accurately measuring and monitoring manufacturing processes has never been more critical. This article explores the importance of precision tools and gages, their types, application areas, and the benefits they provide in today's manufacturing environment.

Understanding Precision Tools and Gages

Precision tools are instruments used to perform tasks with high accuracy and minimal error. They are essential in industries such as automotive, aerospace, electronics, and medical devices, where even the slightest variation can significantly impact performance and safety. Gages, on the other hand, are devices specifically designed to measure an object's dimensions, tolerances, and angles. They ensure that manufactured parts conform to specified standards and tolerances.

Types of Precision Tools and Gages

1. Calipers One of the most common precision tools, calipers can measure internal, external, and depth dimensions. They may be digital or analog and provide measurements in both metric and imperial units.

2. Micrometers Used for measuring small distances with extreme accuracy, micrometers are fundamental in precision engineering. They can measure thickness, outside diameter, and inside diameter with precision up to one-thousandth of a millimeter.

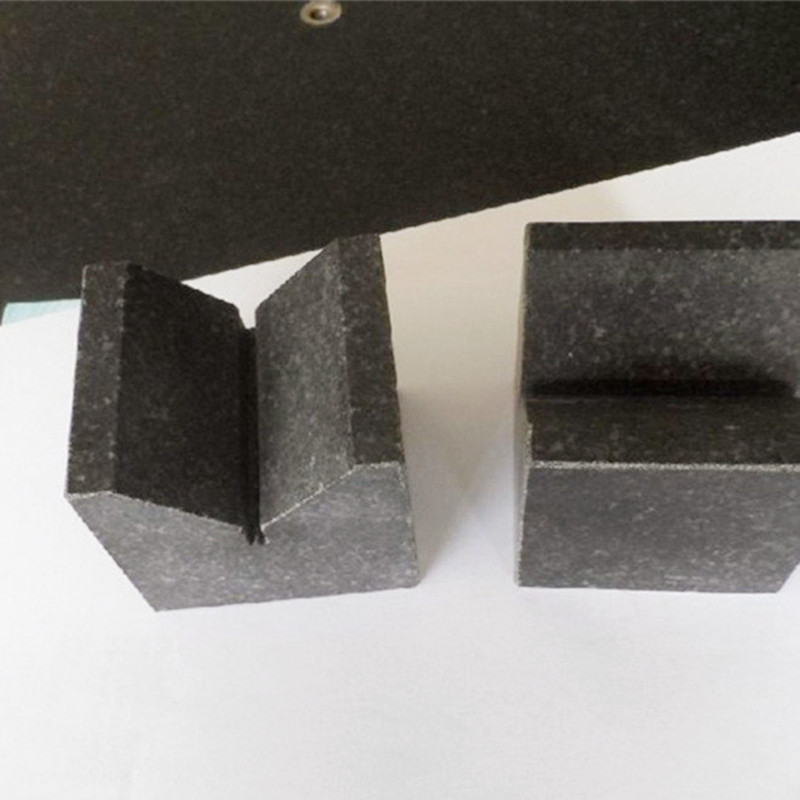

3. Gage Blocks Also known as slip gauges, gage blocks are used for calibrating other measuring tools. They provide a reference standard for length measurements and are essential in achieving high accuracy.

4. Dial Indicators These are used to measure small distances or variations in position. A dial indicator features a dial that displays measurement readings, allowing operators to observe deviations and ensure proper alignment and fit of the parts.

5. Height Gages Height gages measure the height of an object concerning a reference surface. These tools are invaluable in setting up machines and ensuring parts are manufactured to the exact specifications required.

Applications in Industries

Precision tools and gages find extensive applications across various industries

precision tool and gage

- Manufacturing and Assembly In manufacturing, these tools ensure that parts are manufactured to precise specifications, which is crucial for assembly lines. Ensuring that components fit together accurately can minimize assembly errors and reduce production costs.

- Quality Control Quality control departments utilize precision gages to perform inspections and tests on finished products

. The correct use of gages helps maintain consistent quality, reducing the risk of defects that could lead to product failure.- Research and Development In R&D, engineers and designers use precision tools to test prototype components and ensure they meet design specifications before full-scale production begins.

- Maintenance For maintenance technicians, precision tools are essential for evaluating equipment and machinery. Regular measurements can help identify wear and tear, allowing for timely repairs and maintaining operational efficiency.

Benefits of Using Precision Tools and Gages

Incorporating precision tools and gages into manufacturing processes offers numerous benefits

- Improved Accuracy Precision tools allow for the accurate measurement of dimensions, leading to a better fit and function of parts.

- Reduced Waste By ensuring parts are produced to precise specifications, manufacturers can significantly reduce material waste caused by faulty components.

- Enhanced Efficiency Accurate measurements streamline the manufacturing process and reduce the need for rework or adjustments, resulting in more efficient production cycles.

- Increased Customer Satisfaction High-quality products that meet strict tolerances help manufacturers build a reputation for reliability, leading to increased customer loyalty and satisfaction.

Conclusion

Precision tools and gages are indispensable in ensuring the accuracy and quality of manufactured products. As industries continue to advance, the demand for more sophisticated precision instruments will only grow. By embracing these essential tools, businesses can not only enhance their manufacturing processes but also set a benchmark for quality that resonates with customers and stakeholders alike. Investing in precision tools and gages is not merely an option; it’s a necessity for any organization striving for excellence in today’s competitive marketplace.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS